Gravity drive microfluidic device for preparing monodispersed emulsion and method thereof

A microfluidic device and gravity-driven technology, applied in chemical instruments and methods, laboratory containers, colloid chemistry, etc., can solve the problems of high production cost, uneven particle size, and difficulty, and achieve low cost and systematic Simple, overcoming costly and error-prone effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

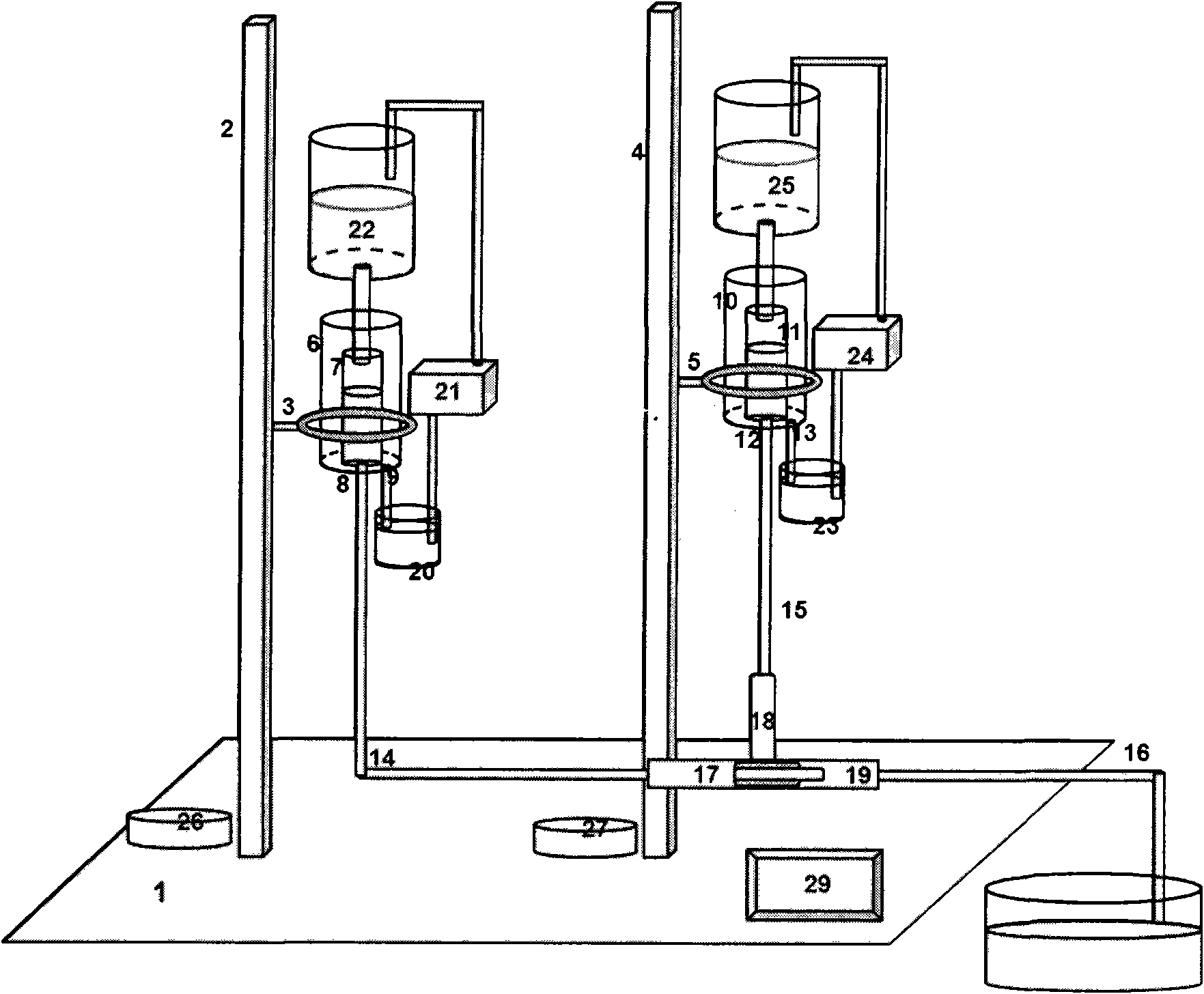

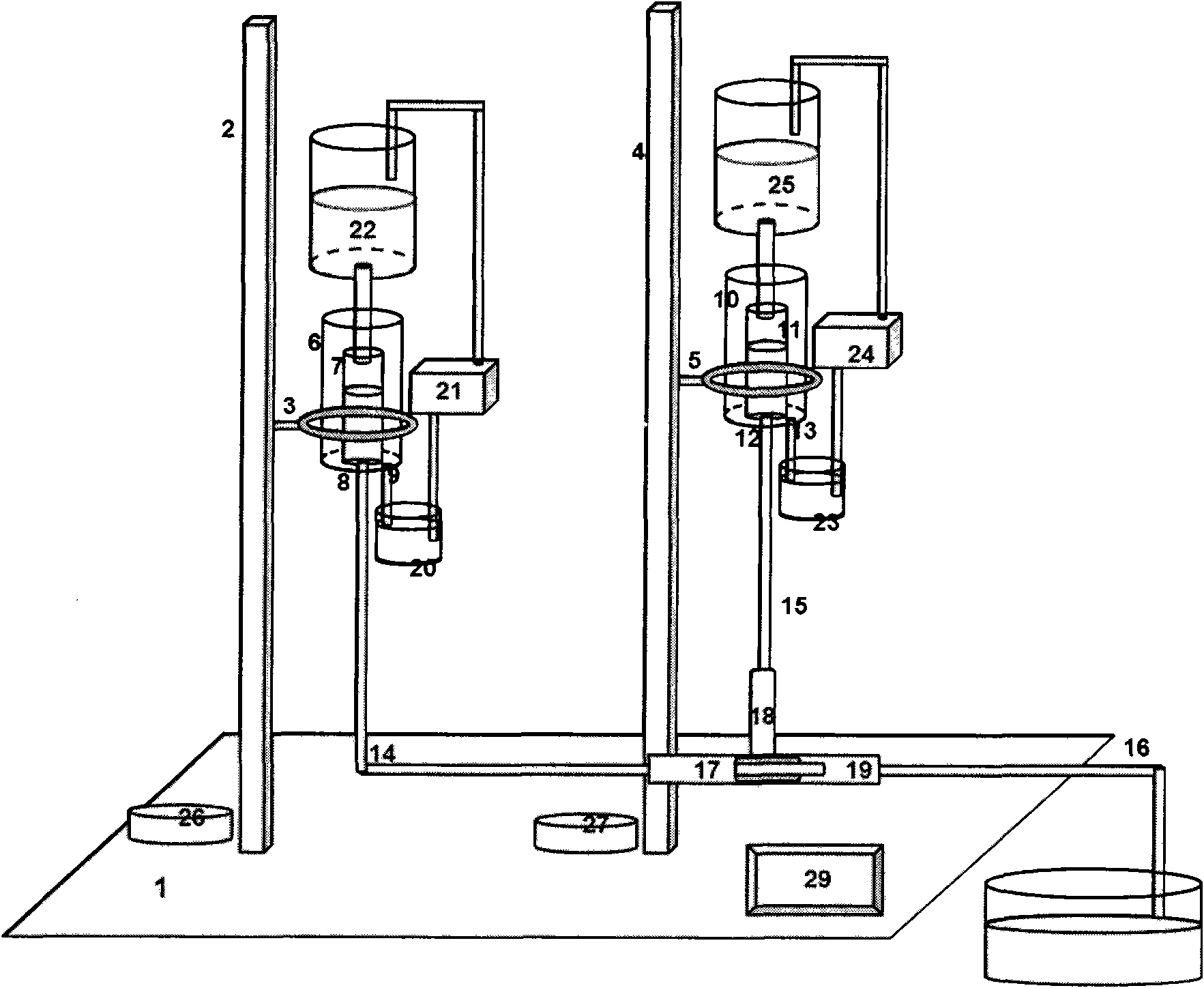

[0022] The present invention designs and manufactures a gravity-driven microfluidic device; the device generates a constant speed based on the fluid gravity of the liquid column, drives the microfluidic system, and controls the height of the liquid column to generate constant driving speeds of different sizes. The shear force and surface tension of the continuous phase fluid on the dispersed phase liquid can prepare droplet templates of different sizes; by controlling the continuous sample feeding parts, the large-scale and continuous preparation of droplets can be realized; and then through curing and drying or ultraviolet polymerization, forming Polymer microspheres that meet the carrier requirements for biological analysis and protein, gene, drug screening, etc.

[0023] Based on the fluid in a liquid column of constant height, a constant flow rate is generated as the driving speed of the microfluidic channel system; the microfluidic channel system is used to make the emulsi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com