Handle operation mechanism with self-locking device used on isolation switch

A technology of isolating switches and self-locking devices, applied in the direction of electric switches, electrical components, circuits, etc., can solve the problems of affecting the service life of products, high dimensional accuracy of parts, and danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

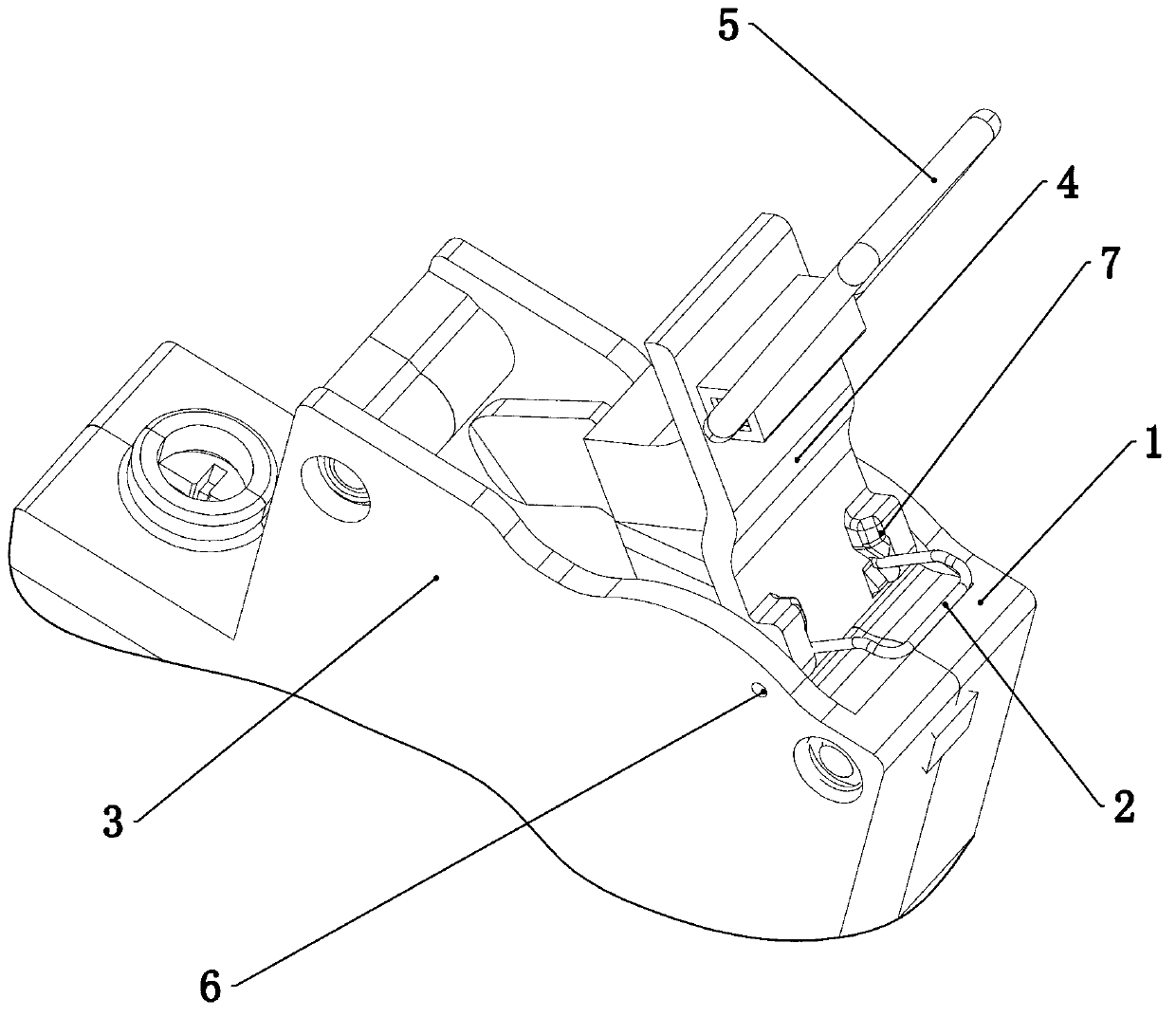

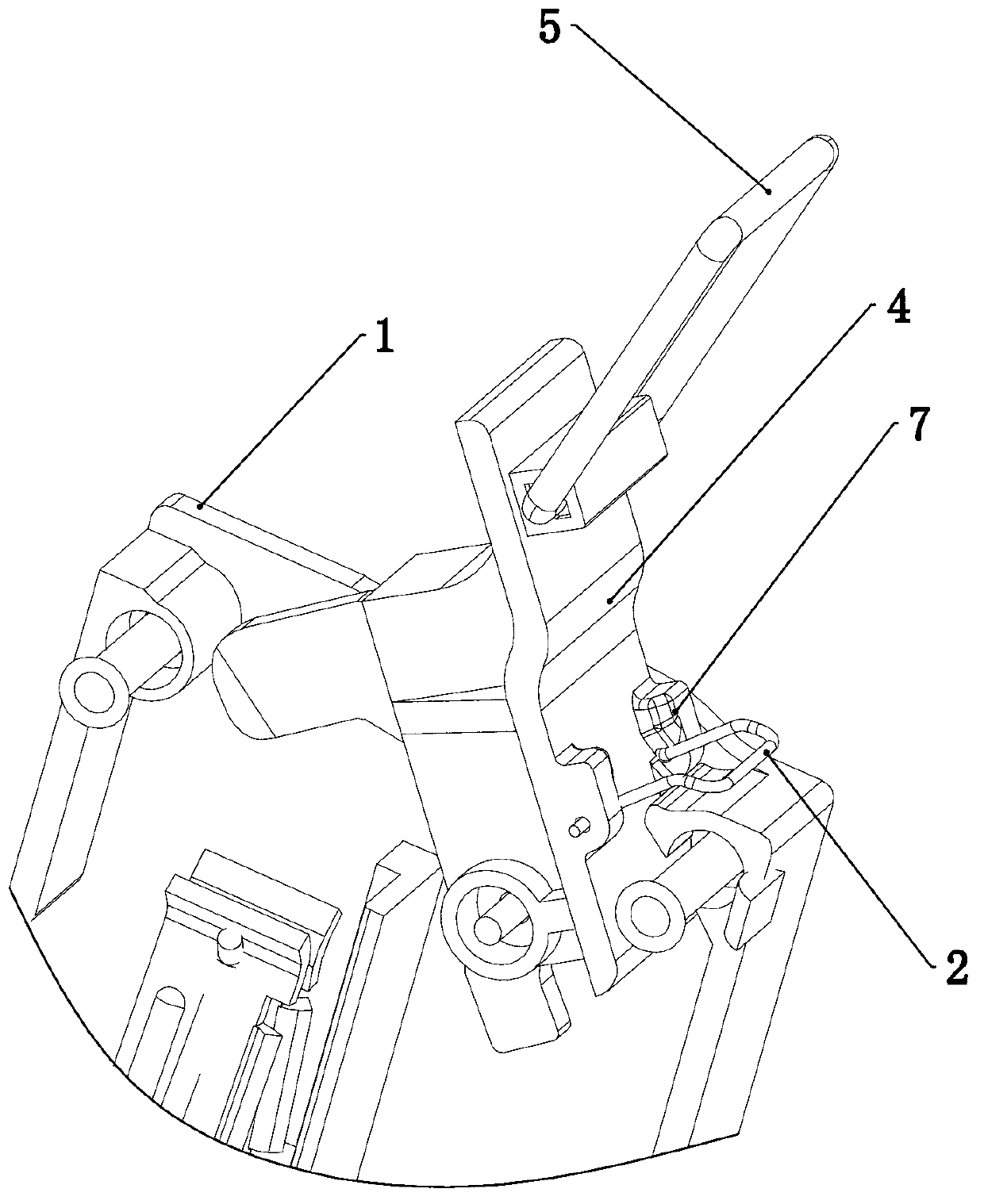

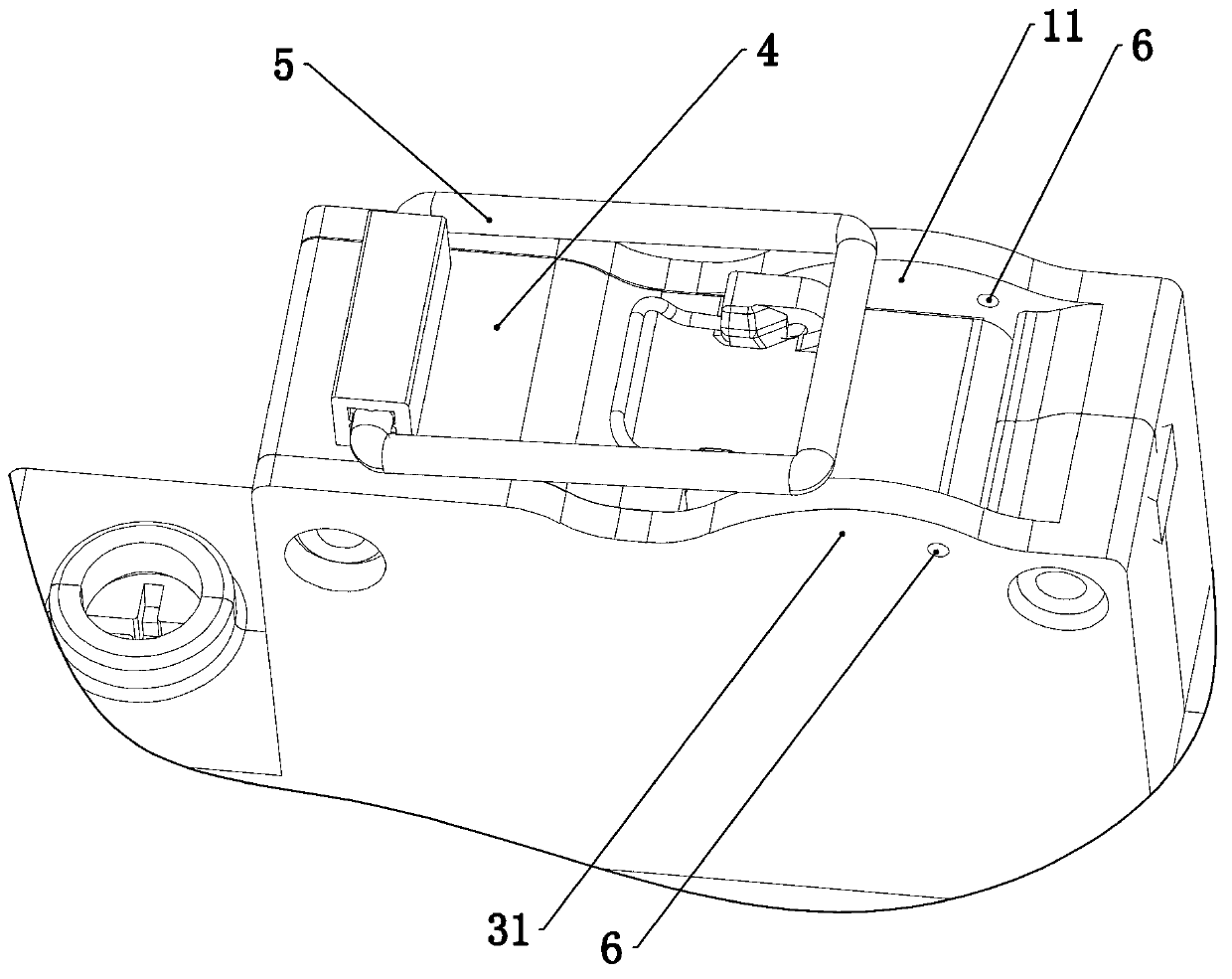

[0017] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, a handle operating mechanism with a self-locking device used on a disconnector includes an insulating handle 4 hingedly arranged on the base 1 and cover 3 of the disconnector, and the inner side of the handle 4 is provided with a moving contact , the outer back of the handle 4 is provided with an elastic member 2, specifically as long as the elastic member 2 is firmly arranged on the handle 4, at least one end of the elastic member 2 is an extension end that can automatically extend along the width direction of the handle 3 21. The elastic part 2 is provided with a force-receiving part 22 that can be pressed by a tool or hand to reset the extended end. Lock the matching lock hole 6 or lock groove, and the stretching end 21 of the elastic part automatically stretches and slides into the lock hole 6 or lock groove after the isolation switch opening handle 4 is tilted to form an automatic conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com