Improved two-stage regeneration method and equipment for catalytic cracking catalyst

A technology for catalytic cracking and regeneration equipment, which is applied in the direction of catalyst regeneration/reactivation, physical/chemical process catalysts, chemical instruments and methods, etc., and can solve problems such as high gas velocity in the coking section of the bed, low catalyst concentration, and destruction of pressure balance , to achieve stable control of the reaction temperature, reduce energy consumption, and improve the effect of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

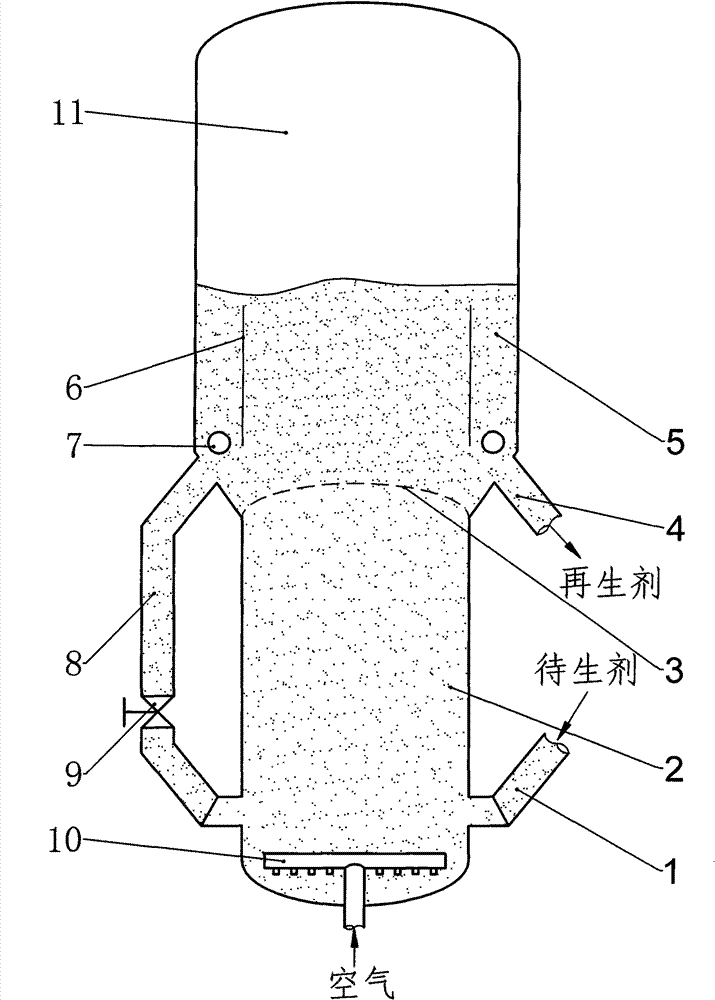

Embodiment 1

[0038] figure 1 A specific structure of the catalytic cracking two-stage regeneration equipment of the present invention is shown. As shown in the figure, when the catalytic cracking two-stage regeneration equipment of this embodiment utilizes the catalytic cracking two-stage regeneration equipment of the present invention to perform coke regeneration of the catalyst, the coke-containing standby catalyst (spent catalyst) passes through the standby standpipe 1 From the bottom of the burnt pot regenerator 2, it enters the burnt pot regeneration section (that is, the first stage of the burnt pot regenerator), the superficial gas velocity is 1.0-3.0m / s, the operating temperature is 630-740°C, and the residence time of the catalyst is 0.5~1.2min. A main wind enters the bottom of the first-stage coke tank regenerator evenly from the gas distributor 10, and its flow rate accounts for 85-99% of the total main air flow of the regenerator, and the coke on the standby agent burns with t...

Embodiment 2

[0041] figure 2 An embodiment of another technical solution of the present invention is shown. The difference from Example 1 is that a dilute-phase conveying pipe 12 is installed at the bottom of the burnt tank regenerator 2, and its gas velocity is 3-7m / s. The catalyst transported by the catalyst circulation pipe 8 of the layer regenerator first enters the bottom of the dilute phase transport pipe 12 and then enters the coke tank 2 together. Due to the high gas velocity in the dilute-phase conveying pipe 12, the turbulent intensity of the particles is relatively high, which is conducive to better contact heat exchange between the two streams of catalysts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com