Ocean source Bacillus barbaricus SCSIO 02429 and method for preparing squid small peptide by using same

A technology for squid and squid viscera is applied in the field of preparing squid small peptides, which can solve the problems of excessive hydrolysis, difficult absorption and utilization of crude protein, low hydrolysis rate of crude protein, etc. The effect of reducing seedling mortality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

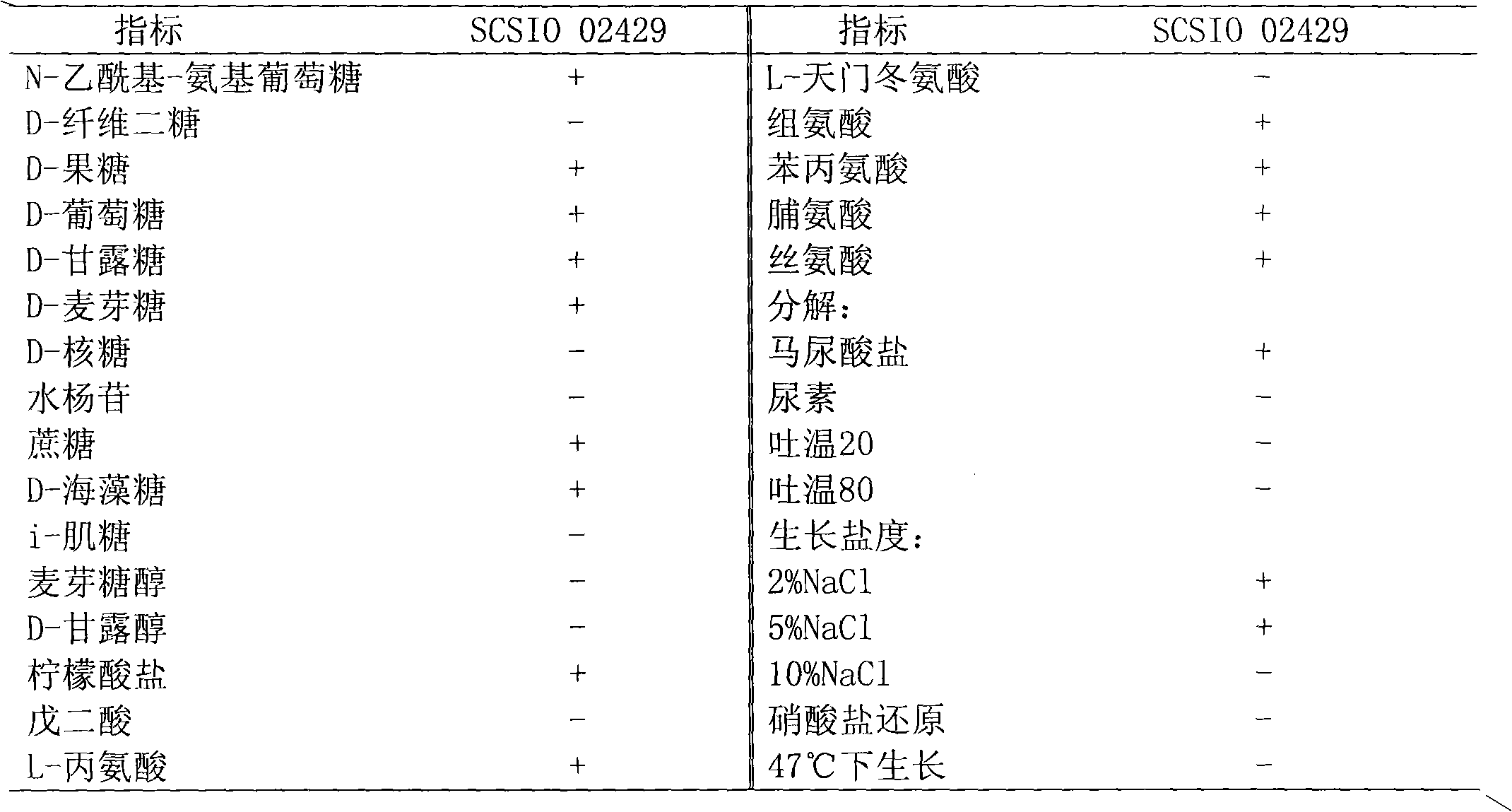

Image

Examples

Embodiment 1

[0021] Add 10 g of peptone, 5 g of yeast extract, 10 g of sodium chloride, and 15 g of agar into 1 L of water, and adjust the pH to 7.0 to obtain a strain activation medium.

[0022] Weigh squid viscera slurry 100g, peptone 25g, yeast extract 25g, compound salt 50g, add deionized water 5000mL, heat and dissolve, adjust pH to 7.0, move into fermenter, steam sterilization, obtain enzyme-producing fermentation medium, wherein The compound salt is composed of 20.9g of sodium chloride, 8.3g of potassium sulfate, 8.3g of magnesium chloride and 12.5g of ammonium chloride.

[0023] The strain of Bacillus barbaricus SCSIO 02429 was transferred to the strain activation medium and cultured at 30°C for 24h. After activation, add the strain into a fermenter with 5L enzyme-producing fermentation medium, and ferment for 24 hours at pH=7.0, 30°C, stirring speed 100r / min, and aeration ratio 0.2. When the protease activity reaches 2000 units / mL, Fermentation was completed when the aminopolysac...

Embodiment 2

[0030] Add 10 g of peptone, 5 g of yeast extract, 10 g of sodium chloride, and 15 g of agar into 1 L of water, and adjust the pH to 7.0 to obtain a strain activation medium.

[0031] Weigh 150g of squid pulp, 25g of peptone, 25g of yeast extract, 50g of compound salt, add 5000mL of deionized water, heat to dissolve, adjust the pH to 8.0, move into a fermenter, and steam sterilize to obtain an enzyme-producing fermentation medium, in which the compound The salt consisted of 26.6g of sodium chloride, 6.7g of potassium sulfate, 6.7g of magnesium chloride and 10.0g of ammonium chloride.

[0032] The strain of Bacillus barbaricus SCSIO 02429 was transferred to the strain activation medium and cultured at 37°C for 18h. After activation, add the strain into a fermenter with 5L enzyme-producing fermentation medium, and ferment for 12 hours at pH=8.0, 37°C, stirring speed 100r / min, and aeration ratio 0.2. When the protease activity reaches 3000 units / mL, Fermentation was completed whe...

Embodiment 3

[0036] Oni tilapia larvae are provided by Guangdong Baishilian Tilapia Fry Breeding Farm, which is the same batch of Oni tilapia larvae that have been filmed for 1 day. Before the experiment, the larvae were domesticated for 2 days in a 50-liter plastic bucket, and no bait was fed during the domestication period.

[0037] Oni tilapia fry were divided into 1 control group and 4 experimental groups, wherein the feed formula used in the control group was 46% fish meal, 15% malt root, 19% cassava powder, 3% yeast, 1% soybean lecithin, Choline 0.5%, calcium hydrogen phosphate 0.5%, multivitamin 0.4%, combined mineral salt 0.6%, cellulose 8%, soybean oil 1%, sodium alginate 1%, gelatin 4%, the feed formula used in the experimental group 1 was fish meal 41%, the squid small peptide 5% that embodiment 1 obtains, malt root 15%, barley powder 19%, yeast 3%, soybean lecithin 1%, choline 0.5%, calcium hydrogen phosphate 0.5%, multivitamin 0.4%, 0.6% of compound mineral salt, 8% of cellul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com