Polycaprolactone/calcium sulfate composite material and preparation method thereof

A technology of polycaprolactone and composite materials, applied in the field of polycaprolactone/calcium sulfate composite materials and its preparation, can solve the problem of affecting the biocompatibility and degradability of polycaprolactone, restricting application fields, and affecting material mechanics Performance and other issues, to achieve the effect of increased strength, wide range of clinical application fields, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

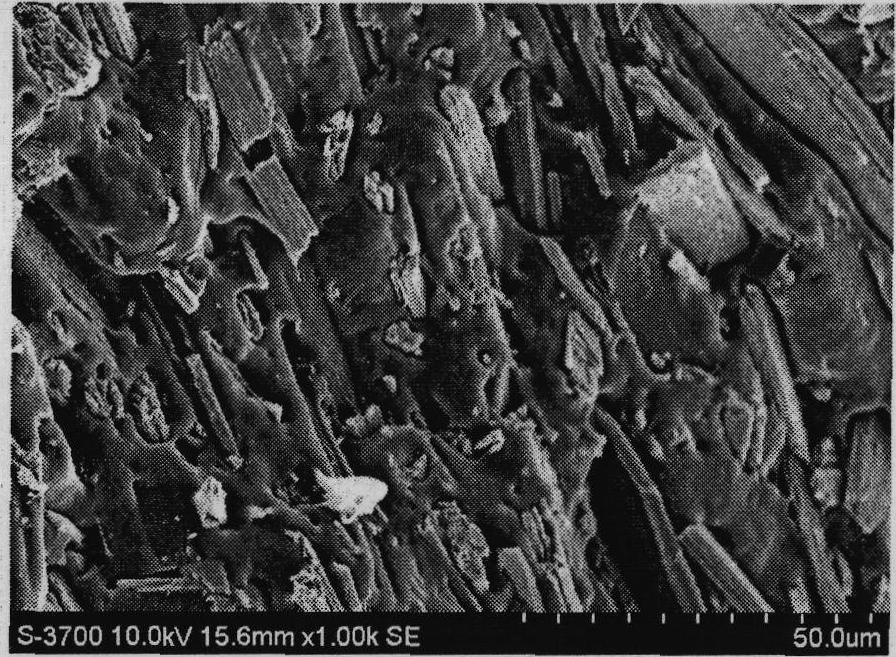

[0028] (1) Co-precipitation method to prepare polycaprolactone and anhydrous calcium sulfate composite materials

[0029] Weigh 16g of polycaprolactone and stir it in a constant temperature water bath at 58°C for 1 hour to completely dissolve it in tetrahydrofuran; weigh 2.4g of anhydrous calcium sulfate powder and stir it at room temperature for 50 minutes to uniformly disperse it in tetrahydrofuran; Pour the tetrahydrofuran solution of caprolactone into the tetrahydrofuran suspension of anhydrous calcium sulfate and mix, and stir with a magnet at room temperature for 2 hours; after ultrasonication for 15 minutes, stir for another 2 hours; quickly pour it into a beaker containing 750ml of absolute ethanol that is being ultrasonicated In the process, a white precipitate was precipitated; the precipitate was repeatedly washed with absolute ethanol; dried in a vacuum oven at 45°C for 1 day to obtain a powdery mixture of polycaprolactone and anhydrous calcium sulfate.

[0030] (2...

Embodiment 2

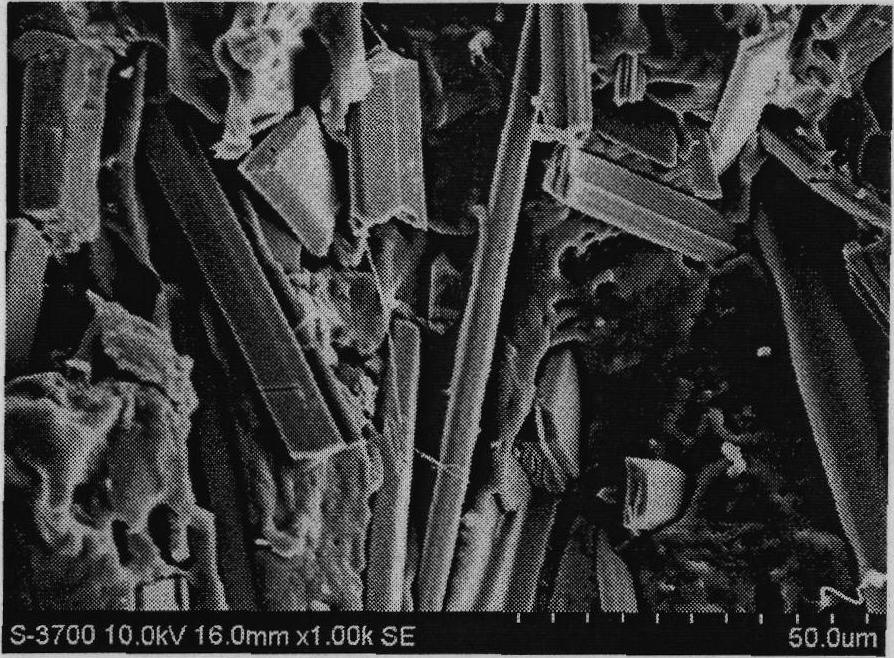

[0033] (1) Co-precipitation method to prepare polycaprolactone and calcium sulfate whisker composite materials

[0034] Weigh 16g of polycaprolactone and stir it in a constant temperature water bath at 50°C for 1 hour to completely dissolve it in tetrahydrofuran; weigh 2.4g of modified anhydrous calcium sulfate powder and stir it at room temperature for 50 minutes to evenly disperse it in tetrahydrofuran ;Pour the tetrahydrofuran solution of polycaprolactone into the tetrahydrofuran suspension of calcium sulfate whiskers and mix, and stir for 2 hours at room temperature; after ultrasonication for 15 minutes, stir for another 2 hours; In the ethanol beaker, a white precipitate was precipitated; the precipitate was repeatedly washed with absolute ethanol; dried in a vacuum oven at 35°C for 1 day to obtain a powdery mixture of polycaprolactone and calcium sulfate whiskers.

[0035] (2) Compression molding of polycaprolactone and modified calcium sulfate whisker composite material...

Embodiment 3

[0038] (1) Surface modification of anhydrous calcium sulfate

[0039] Weigh 0.75g of lecithin and dissolve it in 220ml of absolute ethanol, stir at 35°C for 5 hours, and filter with suction 5 times until impurities are removed. Then add 15g of calcium sulfate, stir for 30 minutes, sonicate for 10 minutes, and stir for another 30 minutes; filter with absolute ethanol and wash 5 times; dry at 50°C in a vacuum oven for 20 hours to obtain surface-modified anhydrous sulfuric acid calcium.

[0040] (2) Co-precipitation method to prepare polycaprolactone and modified anhydrous calcium sulfate composite materials

[0041] Weigh 16g of polycaprolactone and stir it in a constant temperature water bath at 60°C for 1 hour to completely dissolve it in tetrahydrofuran; weigh 2.4g of modified anhydrous calcium sulfate powder and stir it at room temperature for 50 minutes to evenly disperse it in tetrahydrofuran ;Pour the tetrahydrofuran solution of polycaprolactone into the tetrahydrofuran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com