Method for preparing high-purity mono-disperse silicon dioxide hydrosol

A silicon dioxide, monodisperse technology, applied in chemical instruments and methods, inorganic chemistry, silicon compounds, etc., can solve problems such as inconvenience in work, introduction of metal impurities, and restrictions on the localization of HPLC chromatographic packing, so as to improve catalytic activity and accelerate Reaction process, the effect of ensuring high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

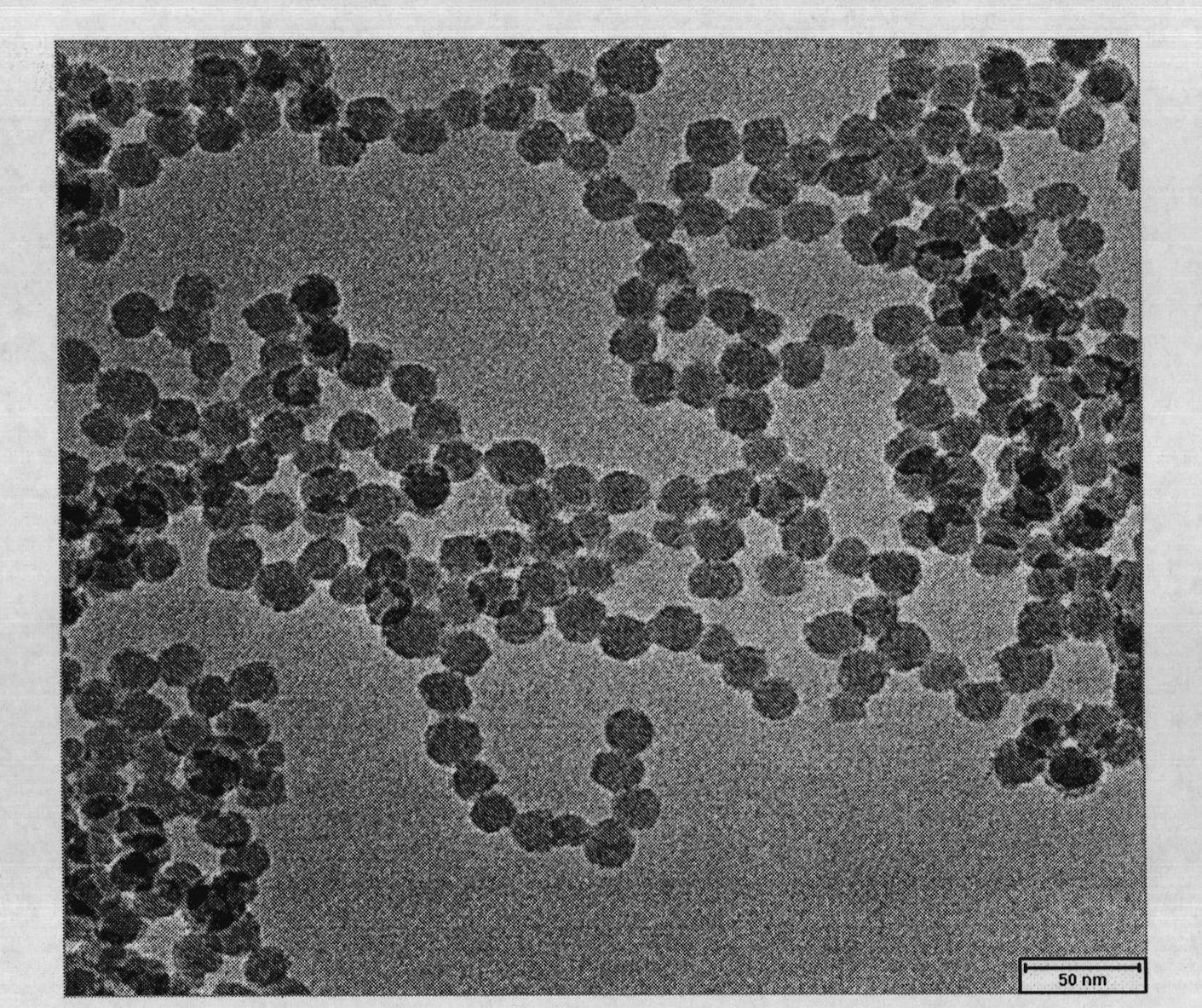

Image

Examples

Embodiment 1

[0021] In the 500ml there-necked flask equipped with a reflux device, add 180ml concentration of 25%-28% analytical pure ammonia water, turn on the water bath and heat up to 50°C, turn on the stirring, set the stirrer speed to 400rpm, add the silicon powder (99.99 %, 200 mesh) about 16.0g (±0.1g), continue to heat up. Wait until the temperature of the water bath reaches 80°C and keep warm, then add 50ml of ammonia water to the reaction vessel at the rate of 10ml drops for half an hour. After keeping warm for about 2 hours, start to feed ammonia gas intermittently, and keep the pH value of the reaction solution not less than 11, and finish the reaction after 4 hours. The obtained silica hydrosol was filtered to remove unreacted silica powder.

[0022] Take three 20ml beakers, label and weigh them respectively. Weigh 2.00g (±0.02g) of the filtered silicon hydrosol into three beakers, weigh the beakers, put them in an oven and dry them at 70°C. Take out the beakers after dryin...

Embodiment 2

[0025]In the 500ml there-necked flask equipped with a reflux device, add 160ml concentration of 25%-28% analytical pure ammonia water, turn on the water bath and heat up to 50°C, turn on the stirring, set the speed of the stirrer to 600rpm, add the silicon powder weighed in advance (99.99 %, 200 mesh) about 16.0g (±0.1g), continue to heat up. Keep warm until the water bath temperature reaches 80°C, then add 40ml of ammonia water to the reaction vessel at the rate of 20ml drops for 1 hour. After keeping warm for about 2 hours, start to feed ammonia gas intermittently, and keep the pH value of the reaction solution not less than 11, and finish the reaction after 4 hours. The obtained silica hydrosol was filtered to remove unreacted silica powder.

[0026] Take three 20ml beakers, label and weigh them respectively. Weigh 2.00g (±0.02g) of the filtered silica sol into three beakers, weigh the beakers and place them in an oven to dry at 70°C. Take out the beakers after drying, w...

Embodiment 3

[0028] In the 500ml there-necked bottle equipped with a reflux device, add 200ml concentration of 25%-28% analytically pure ammonia water, turn on the water bath and heat up to 50°C, turn on the stirring, set the stirrer speed to 600rpm, add the silicon powder (99.99 %, 200 mesh) about 16.0g (±0.1g), continue to heat up. Wait until the temperature of the water bath reaches 80°C and keep warm, then add 60ml of ammonia water to the reaction vessel at the rate of 10ml drops for half an hour. After keeping warm for about 2 hours, start to feed ammonia gas intermittently, and keep the pH value of the reaction solution not less than 11, and finish the reaction after 4 hours. The obtained silica hydrosol was filtered to remove unreacted silica powder.

[0029] Take three 20ml beakers, label and weigh them respectively. Weigh 2.00g (±0.02g) of the filtered silicon hydrosol into three beakers, weigh the beakers, put them in an oven and dry them at 70°C. Take out the beakers after dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com