Method for preparing silver micro-powder for high-temperature sintering silver pastes

A technology of high-temperature sintering and silver micropowder, which is applied in the field of preparation of functional silver micropowder, can solve problems such as difficult batch production, difficulty in solid-liquid separation and collection, high energy consumption of high-speed centrifugal separation, etc., and achieve stable industrial production and easy collection and washing , Improve the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention is a method for preparing silver micropowder for high-temperature sintered silver paste, comprising the following steps:

[0030] (1) Prepare silver ammonia solution, add polymer thickener solution, fully stir and dissolve to form a sol-like silver liquid system. Wherein, the polymer thickener solution is selected from one or a mixed solution of gum arabic, gelatin, polyanion cellulose, methyl cellulose, sodium carboxymethyl cellulose.

[0031] (2) Prepare a reducing system composed of reducing agent, sodium hydroxide and polymer thickener solution, and fully stir to form a sol-like reducing system. In the system, one or more of vitamin C, formaldehyde, hydrazine hydrate, formic acid and sodium borohydride can be selected as the reducing agent, and the mass ratio of reducing agent to silver is 1:1-20; the mass ratio of silver ion to sodium hydroxide It is 4~6:1. Optimally, the mass ratio of reducing agent to silver is 1:1.2-15; the mass ratio of silver i...

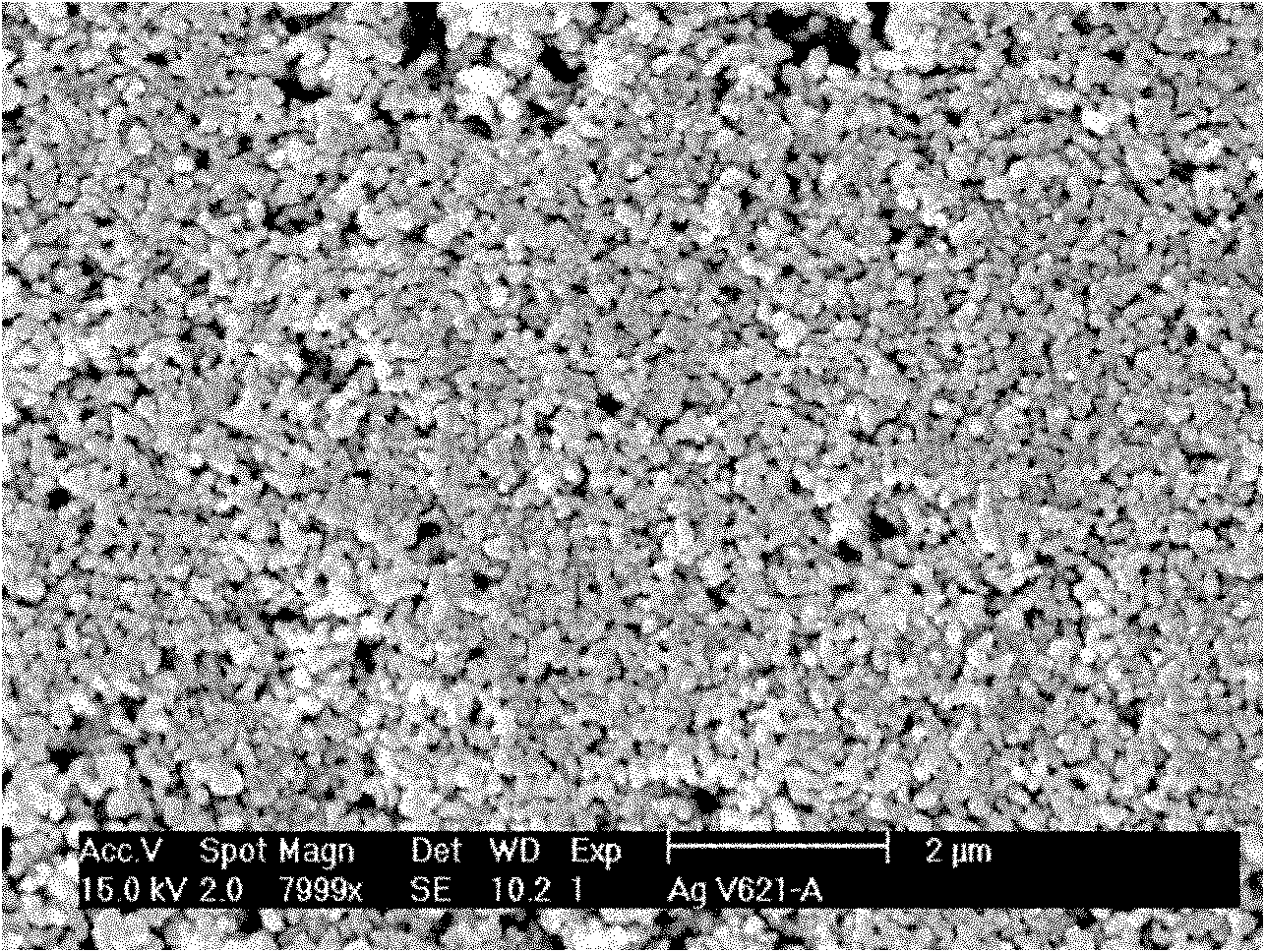

Embodiment 1

[0038] (1) Weigh 50 g of polyanionic cellulose and dissolve it in 1000 ml of deionized water, stir well to dissolve into sol A with a mass ratio of 5%.

[0039] (2) Weigh 40g of analytically pure AgNO 3 Dissolve it in 200ml of deionized water to make a silver nitrate solution; add 30-40ml of 25-28% ammonia water to the silver nitrate solution until the solution turns from turbid to clear to obtain a silver ammonia solution. Then add 20ml of formulated sol A, add deionized water to dilute to 400ml, stir and mix well to obtain a silver sol system.

[0040](3) Weigh 5g of analytically pure NaOH and dissolve it in 200ml of deionized water. After stirring to dissolve fully, add 5ml of 80% analytically pure hydrazine hydrate and 20ml of formulated sol A, and finally add deionized water to dilute to 400ml. Thoroughly stir and mix uniformly to obtain a reduced sol system.

[0041] (4) Weigh 1.5g of polyvinylpyrrolidone PVP, heat and dissolve it in 200ml of deionized water to prepare...

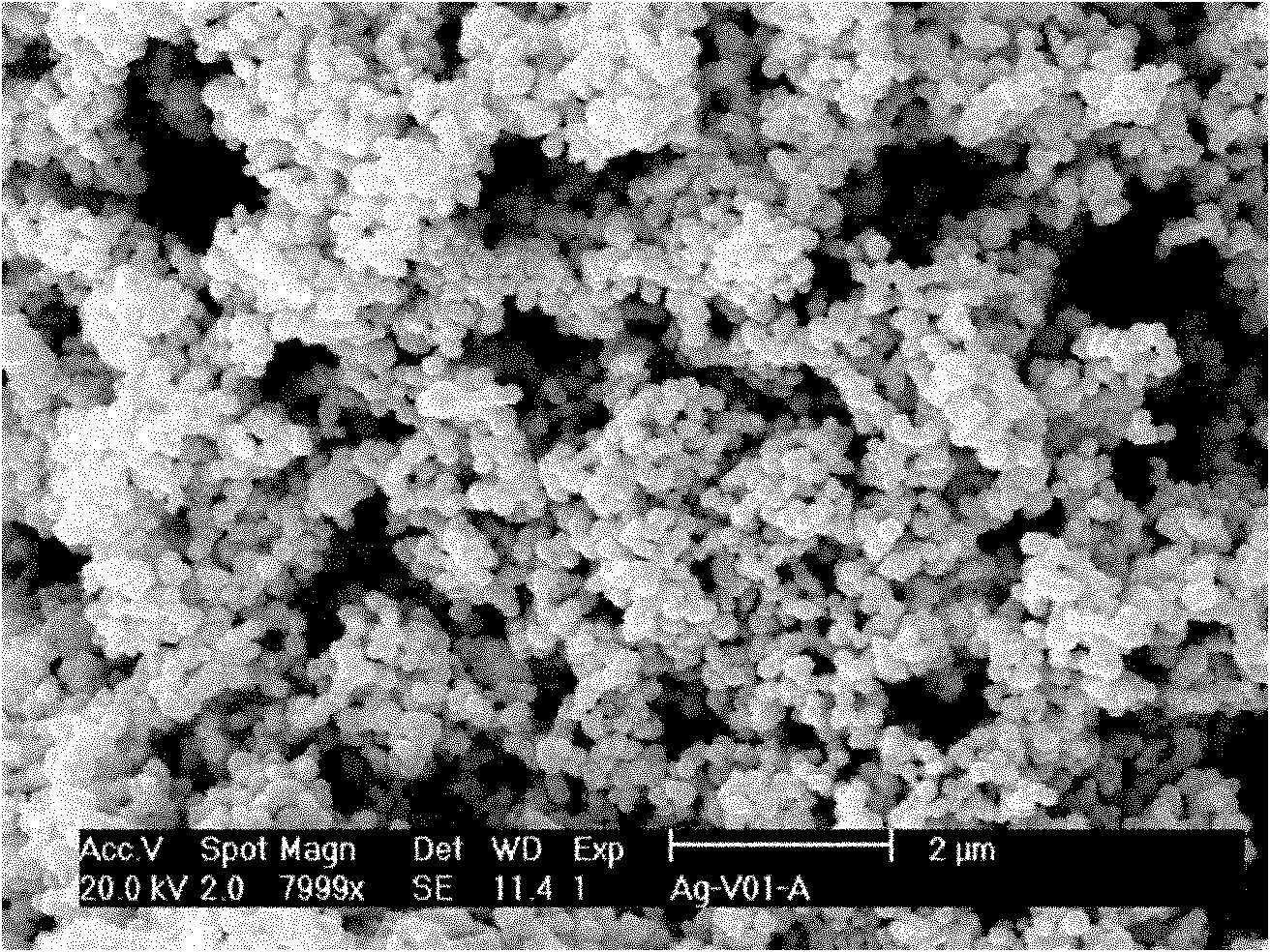

Embodiment 2

[0046] (1) Weigh 50 g of polyanionic cellulose and dissolve it in 1000 ml of deionized water, stir well to dissolve into sol A with a mass ratio of 5%.

[0047] (2) Weigh 40g of analytically pure AgNO 3 Dissolve it in 200ml of deionized water to make a silver nitrate solution; add 30-40ml of 25-28% ammonia water to the silver nitrate solution until the solution turns from turbid to clear to obtain a silver ammonia solution. Then add 10ml of formulated sol A, add deionized water to dilute to 400ml, stir and mix well to obtain a silver sol system.

[0048] (3) Weigh 5g of analytically pure NaOH and dissolve it in 200ml of deionized water. After stirring to dissolve fully, add 5g of analytically pure formaldehyde and 10ml of formulated sol A, and finally add deionized water to dilute to 400ml, stir and mix evenly to obtain Reduce the sol system.

[0049] (4) Weigh 1.5g of polyvinylpyrrolidone PVP, heat and dissolve it in 200ml of deionized water to prepare a protective solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com