Method for reinforcement repair of pipeline by using metal hot spraying and fibrous composite

A technology of fiber composite materials and composite materials, which is applied in the field of on-site reinforcement and repair of pipe defects, can solve the problems of large shrinkage of resin fillers, low bonding strength of composite materials and steel pipes, and unstable quality of resin fillers. It achieves the effects of low shrinkage, easy control of spraying thickness and good economic benefits

Inactive Publication Date: 2011-02-09

CHENGDU DONGLI REINFORCEMENT TECH

View PDF7 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The metal alloy / fiber composite material reinforcement repair system has been developed, which solves the problem of low bonding strength between composite material and steel pipe body, large shrinkage rate of resin filler, and poor quality of resin filler in traditional composite material reinforcement repair technology. unstable problem

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0023] In order to further illustrate the construction technology involved in the present technology, the following examples are given. However, these examples do not limit the scope of the present invention in any way.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Login to View More

Abstract

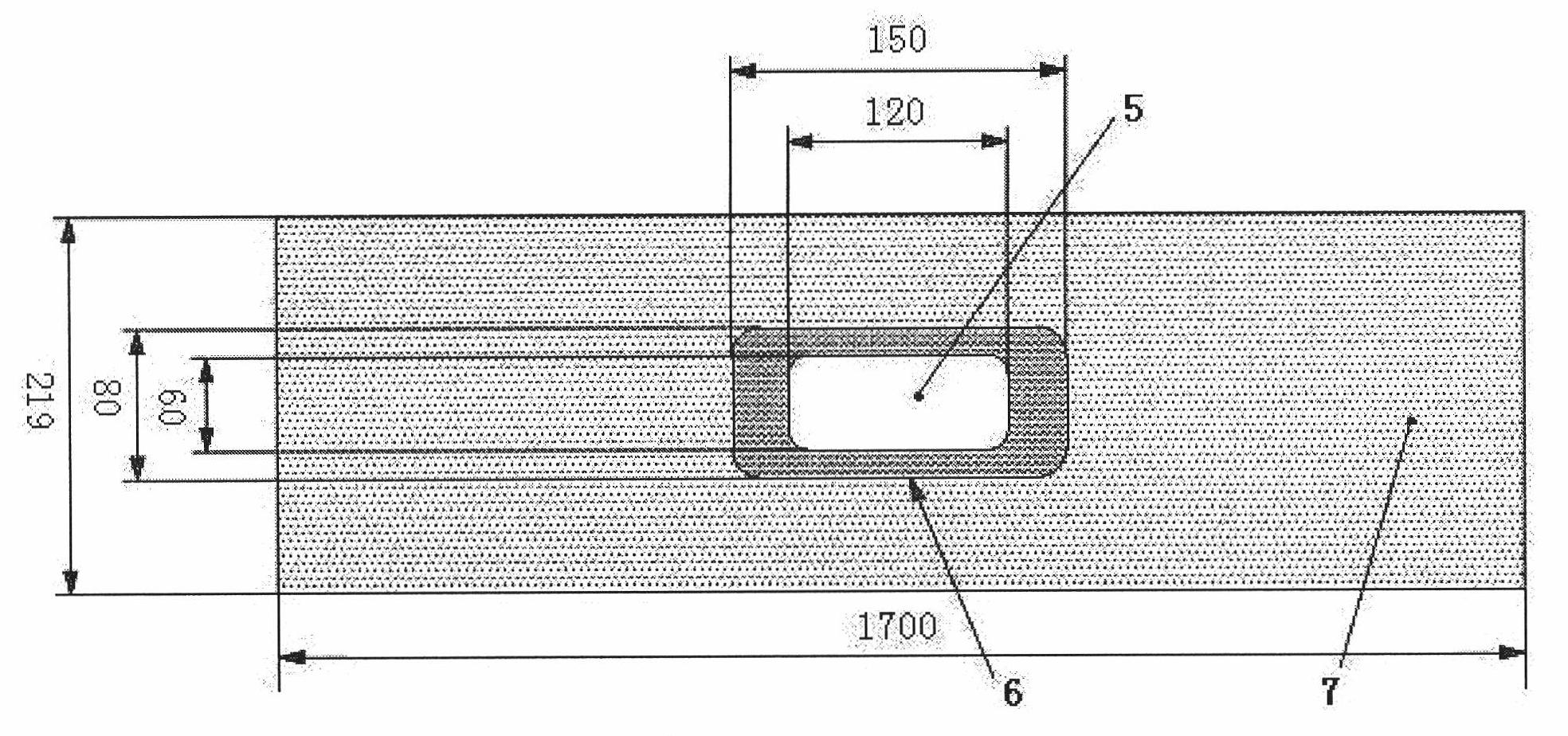

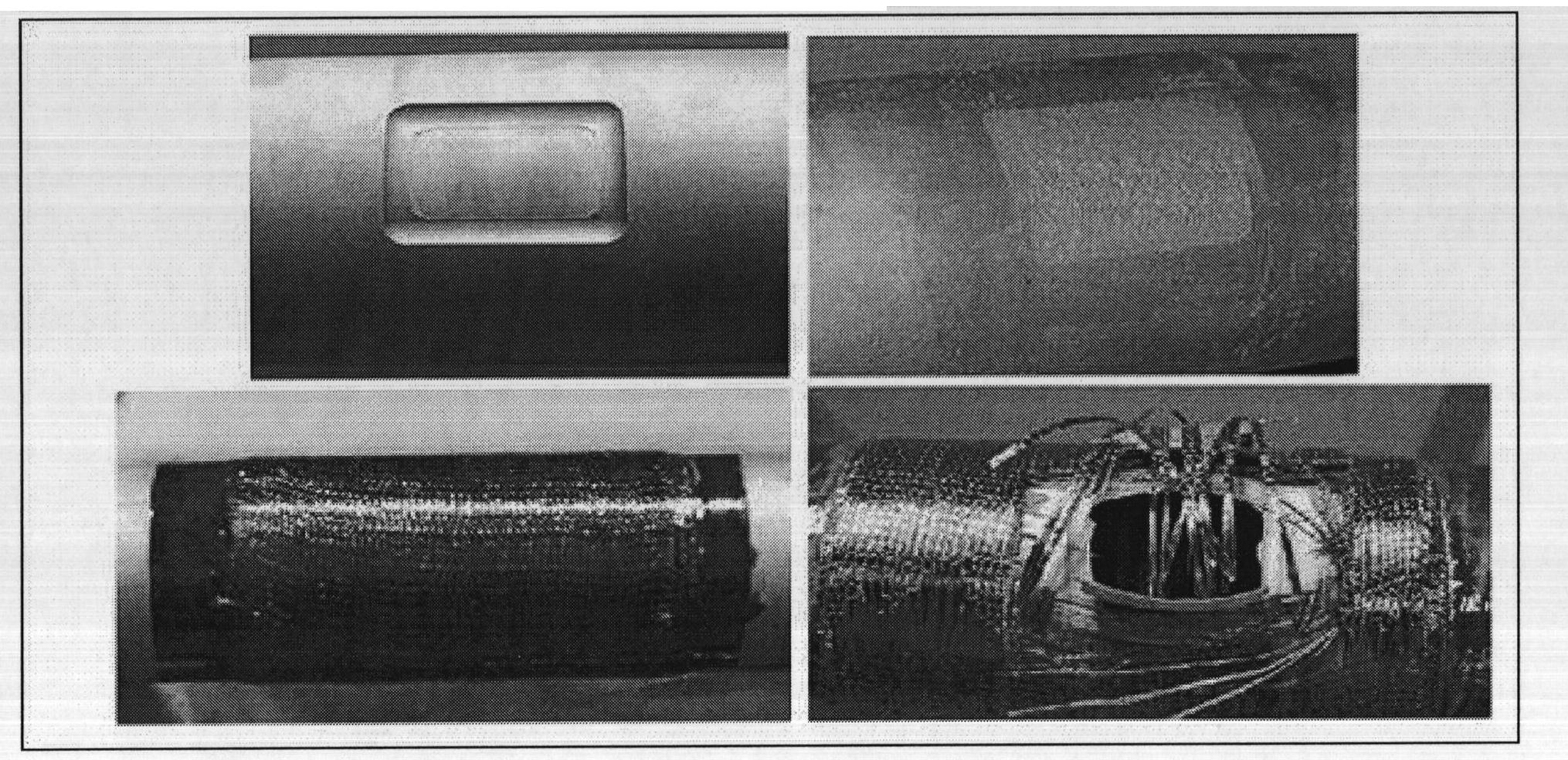

The invention relates to a method for reinforcement repair of a metal pipeline with the defect, which is particularly suitable for on-site operations under the condition of continuous transmission of the pipeline. The method is characterized in that: after the surface of a pipe body is treated by using sand blast (recommended) or an electric angle grinder, the defect 2 is filled and leveled up by hot spraying metal alloy, and the surface of the integral circle of the pipe body 1 is sprayed to form a metal alloy basement layer 3, wherein the metal alloy basement layer has the excellent compression strength; a fiber resin composite 4 formed by fibers and an epoxy bonder is wound on the basement layer, the cured fiber resin composite has the high tensile strength and elastic modulus, so the fiber resin composite limits the radial dilatational strain at the defect, and reduces the stretching stress and stretching strain at the defect through the metal alloy basement layer to realize the reinforcement repair on the defect of the pipeline.

Description

technical field [0001] The invention relates to a method for reinforcing and repairing the pipe body defects of steel pressure pipes by utilizing externally wound fiber-reinforced plastic composite materials after metal thermal spraying. Reinforcement repair. Background technique [0002] Steel pipelines are the main carrier in my country's fluid medium transmission projects, but corrosion will occur under the action of the environment (atmosphere, soil, microorganisms, etc.) and the internal transmission medium, and the strength reduction and pitting and perforation caused by corrosion are very serious. Leakage Accidents happen from time to time, causing huge losses to the production of enterprises. For the repair of volume defects such as corrosion pits and grooves on the outer wall caused by corrosion, in the past, the methods of on-site welding to repair scars, sleeve sleeves or section cutting and re-welding of new pipe sections were mainly used. The ductile-brittle tr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C23C4/04

Inventor 周祥吴林玲

Owner CHENGDU DONGLI REINFORCEMENT TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com