Method for preparing ultrafine high-purity SiO2 from volcanic ash

A technology of volcanic ash and fine height, which is applied in the field of preparation of ultra-fine high-purity SiO2, which can solve the problems of high cost, uneven particle size, and narrow primary particle size distribution, and achieve the effect of reducing preparation cost, uniform distribution, and abundant reserves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

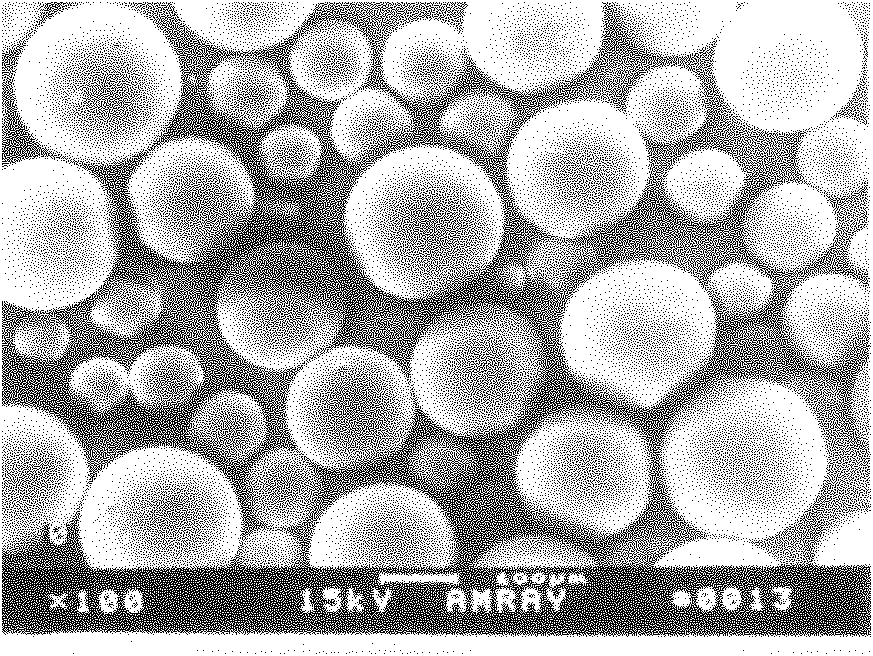

Image

Examples

Embodiment 1

[0022] A kind of superfine high-purity SiO prepared by volcanic ash 2 method, consisting of the following steps:

[0023] A. Weigh SiO 2 100 parts by weight of volcanic ash with a weight content of ≥50% is pulverized to a particle size of ≤1mm.

[0024] B. Add and disperse the volcanic ash into hydrochloric acid at 60°C, stir for 90 minutes, filter and wash with water to obtain purified volcanic ash;

[0025] C. Transfer the purified volcanic ash into 300 parts by weight of water, heat to 70°C, stir and add SiO in the volcanic ash 2 Equivalent NaOH forms a homogeneous sol system; another 3 parts by weight of hydrophobic substances are weighed and dispersed in the sol system; Microemulsion system, add acidic substances dropwise to produce precipitation, until no precipitation occurs; filter to obtain the precipitate, wash with water, and dry to obtain the product.

[0026] After testing, the ultrafine high-purity SiO produced in this example 2 The particle size is 90±15nm....

Embodiment 2-24

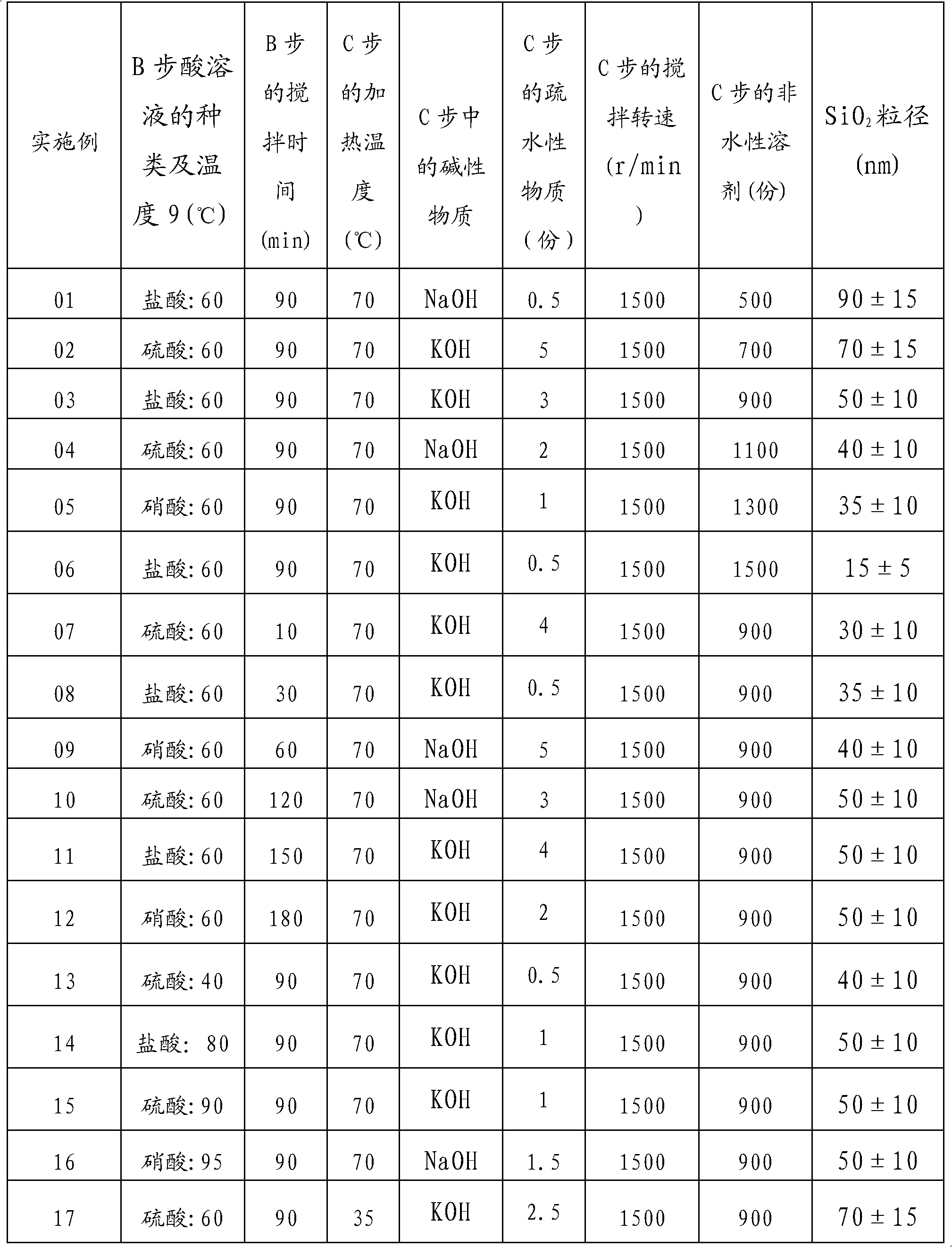

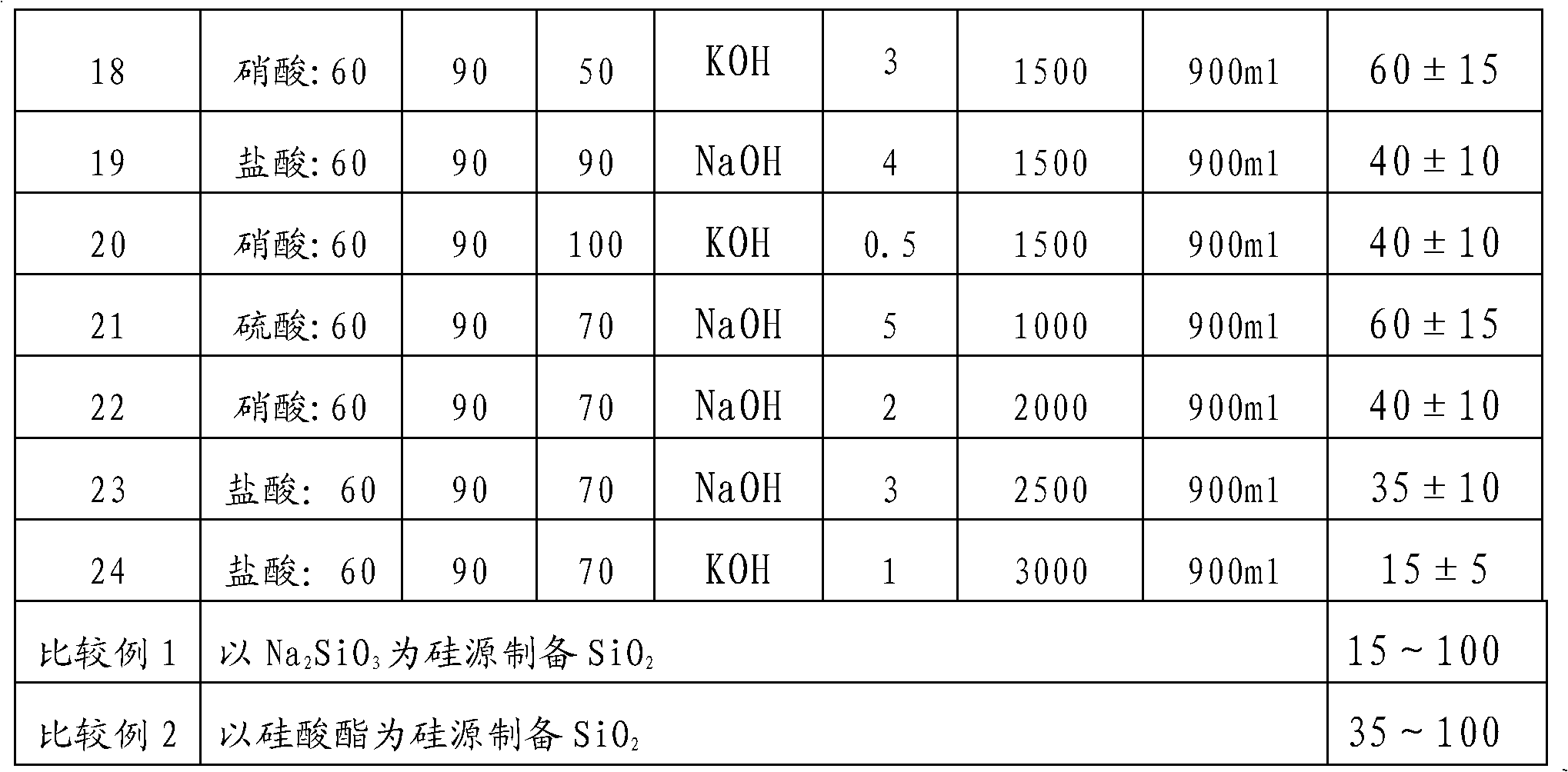

[0028] The preparation ultrafine high-purity SiO of embodiment 2-24 The method all is identical with the method for embodiment 1, and difference is only: the raw material type that each embodiment selects, proportioning and specific process parameter are changed into listed in the following table Corresponding raw material types, proportions and specific process parameters. Non-aqueous substances in the table refer to organic solvents that are immiscible with water.

[0029] The type of raw material, proportioning ratio, process parameters and the product SiO that are selected in embodiment 1-24 2 Particle size table

[0030]

[0031]

[0032] As can be seen from the above table, the prepared SiO of the present invention 2 Small particle size and uniform distribution.

[0033] The hydrophobic substance in the present invention can be any existing oil-soluble surfactant or silane coupling agent. The water-immiscible organic solvent used in the present invention is als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com