Method for preparing cobalt-based amorphous alloy wire

An amorphous alloy and cobalt-based technology, which is applied in the field of preparation of cobalt-based amorphous alloy wire, can solve problems such as no major breakthroughs, and achieve uniform performance, smooth surface, and high roundness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

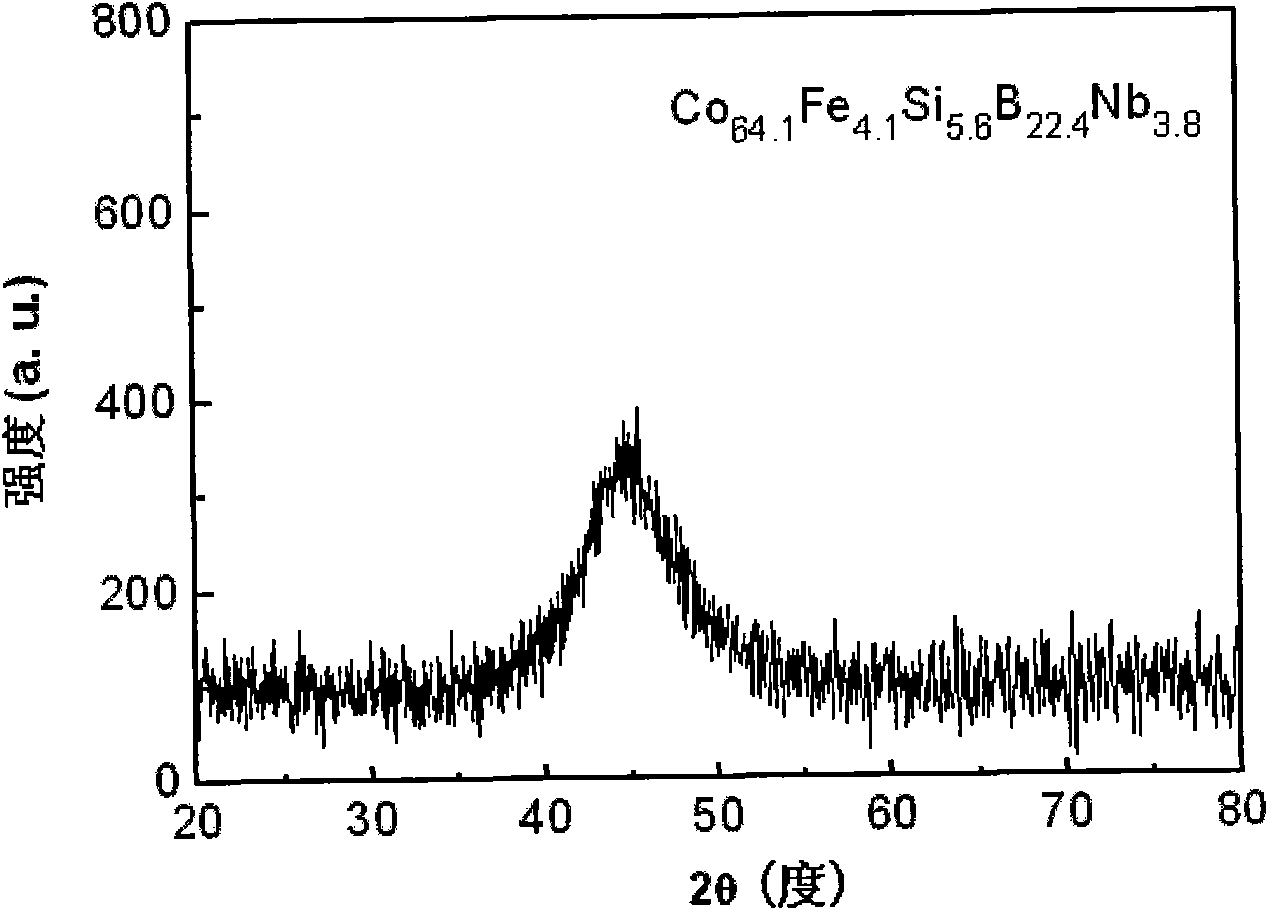

Embodiment 1

[0028] The composition molecular formula of the cobalt-based amorphous alloy wire of this example is Co 64.1 Fe 4.1 Si 5.6 B 22.4 Nb 3.8 , the preparation steps are as follows: prepare 50 grams of raw materials Co, Fe, B, Si and Nb with a purity greater than 99% according to the composition of the cobalt-based amorphous alloy wire of this embodiment, and then use a high-frequency induction melting furnace under the protection of argon to carry out For smelting, the smelting current is 6.5A, after the raw material is completely melted, it is refined for 12 minutes.

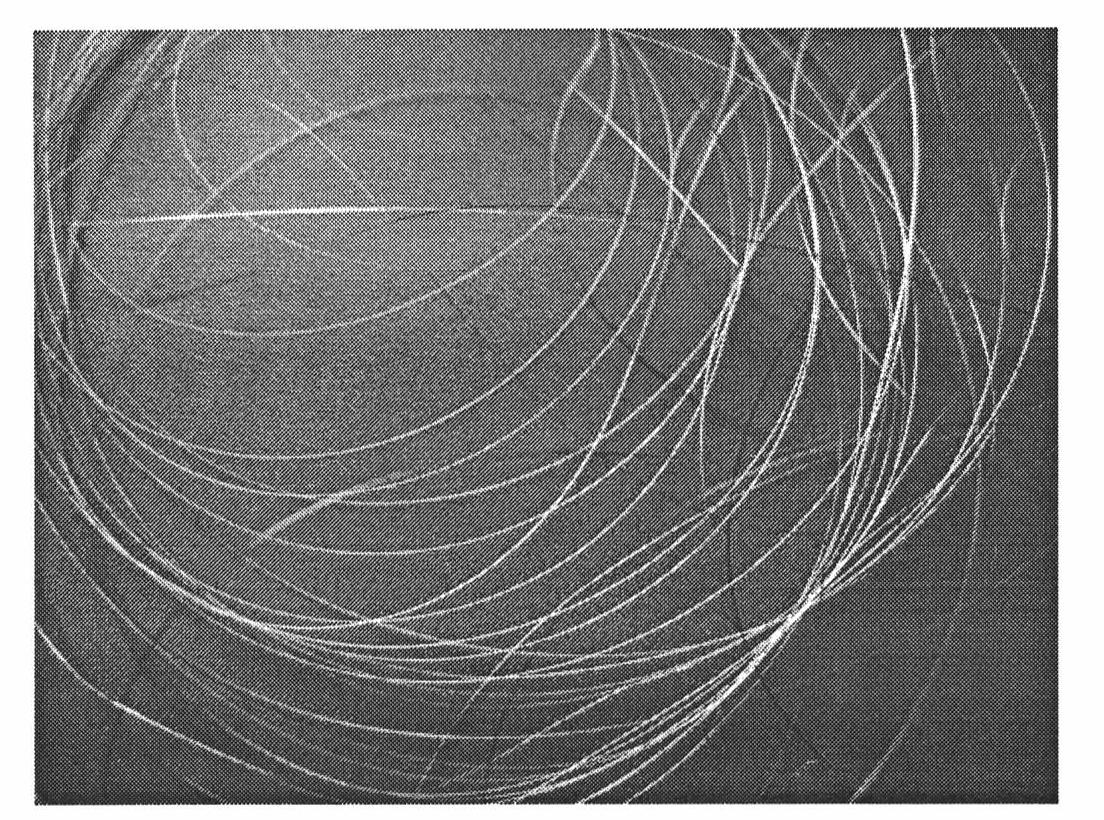

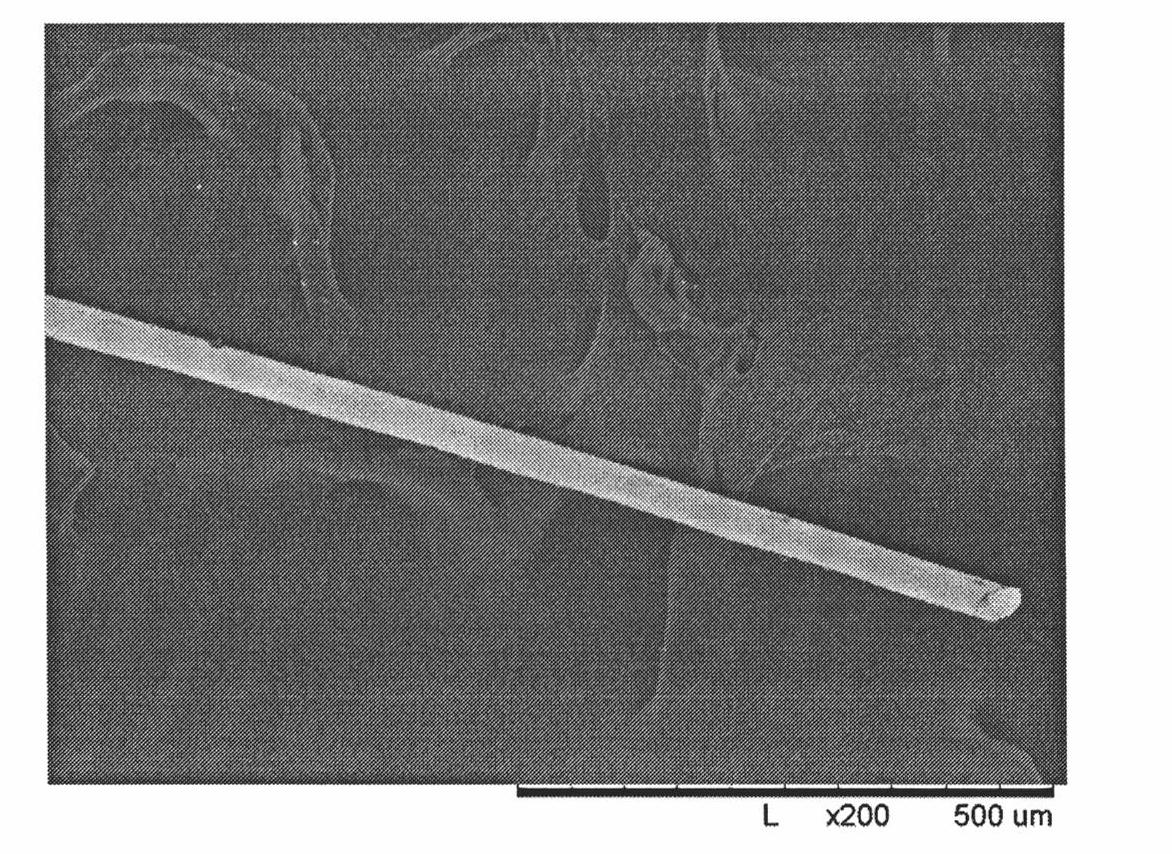

[0029] Cut the smelted alloy rod into short rods of about 10mm, put them into the crucible, and evacuate the entire cavity to reach 5×10 -3 After Pa, close the vacuum system and flush into 0.5 atmospheres of argon for protection. Then start the high-frequency induction melting device. After the master alloy is completely melted to form a steamed bun-like melt, start the copper roller and the copper roller wate...

Embodiment 2

[0031] The molecular formula of the cobalt-based amorphous alloy wire of this example is Co 64.1 Fe 4.1 Si 5.6 B 22.4 Nb 3.8 , the preparation steps are as follows: prepare 50 g of raw materials Co, Fe, B, Si and Nb with a purity greater than 99% according to the composition of the cobalt-based amorphous alloy wire of this embodiment, and then use a high-frequency induction melting furnace to melt under the protection of argon , the smelting current is 7.0A, after the raw material is completely melted, it will be refined for 15 minutes.

[0032] Cut the smelted alloy rod into short rods of about 10mm, put them into the crucible, and evacuate the entire cavity to reach 6×10 -3 After Pa, close the vacuum system and flush into 0.6 atmospheres of argon for protection. Then start the high-frequency induction melting device, and after the master alloy is completely melted to form a steamed bun-like melt, start the copper roller and the copper roller water cooling circuit, set t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com