Cable thermoplastic elastomer composition and preparation method thereof

A thermoplastic elastomer and composition technology, applied in the direction of plastic/resin/wax insulators, organic insulators, etc., can solve the problems of shortage and high entry threshold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 5

[0032] Embodiment operation process: the preparation method of thermoplastic elastomer composition for electric cable, has the following steps:

[0033] 1) Accurately weigh each component according to the mass percentage set by the formula;

[0034] 2) Divide the components of the above 1) into three parts according to the category of resin, flame retardant and small materials, small materials include char-forming agents, compatibilizers, flame-retardant synergists, antioxidants, processing aids, and Add weightless electronic scales respectively;

[0035] 3) Through the weight loss electronic weighing system, it enters the screw cylinder of the BUSS machine uniformly from the feeding port according to the preset ratio; through the unique reciprocating single-screw mixing process of the BUSS machine, the granulation process is completed by underwater granulation and the finished product is obtained.

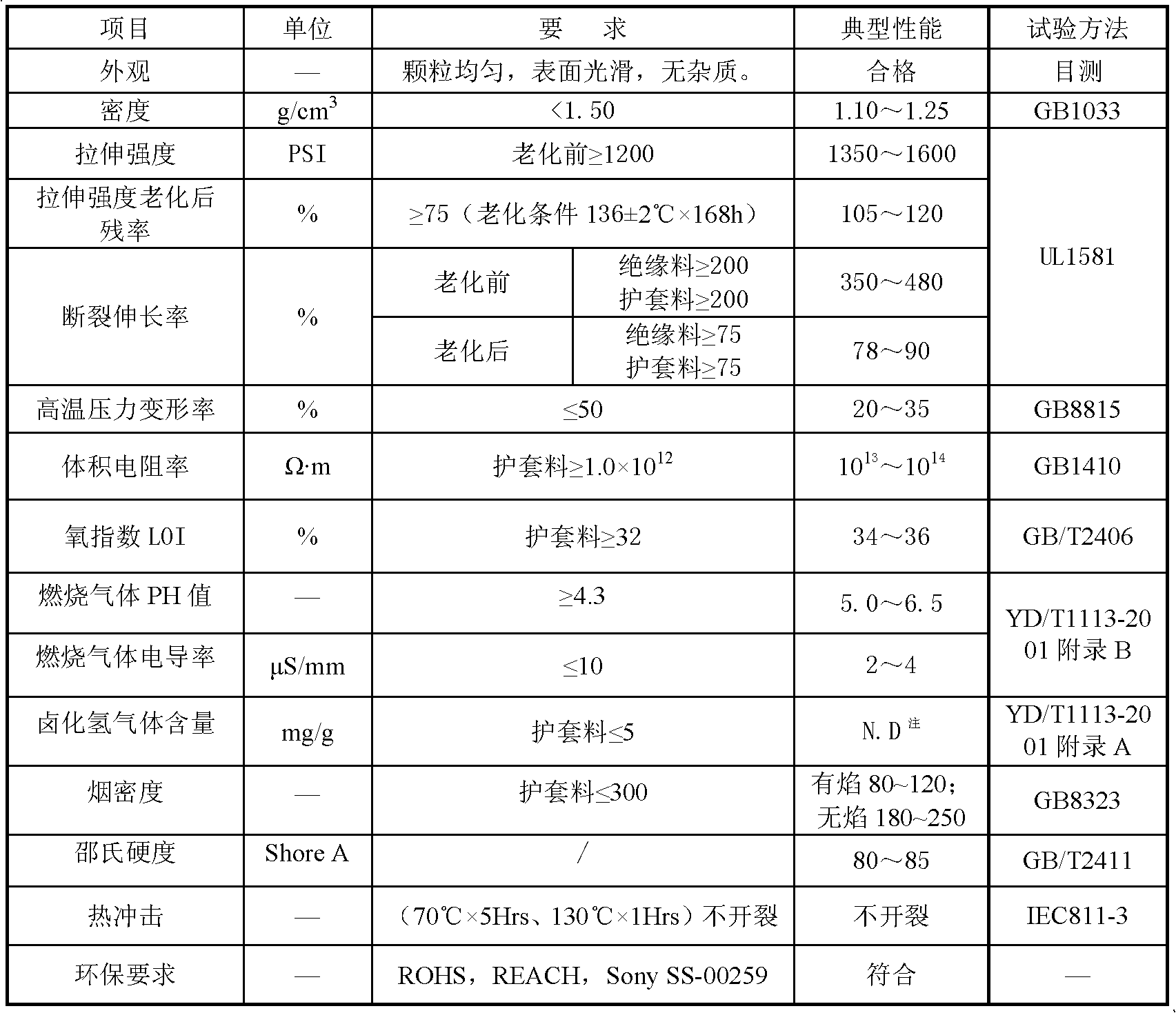

[0036] The following table is the relevant performance parameters of the raw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com