Thermally conductive molded body

A thermal conductivity and molding technology, applied in the direction of semiconductor devices, semiconductor/solid device parts, electric solid devices, etc., can solve the problems of liquid polymer viscosity increase, low flame retardancy, manufacturing difficulties, etc., to achieve oil leakage less, excellent flame retardancy, and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

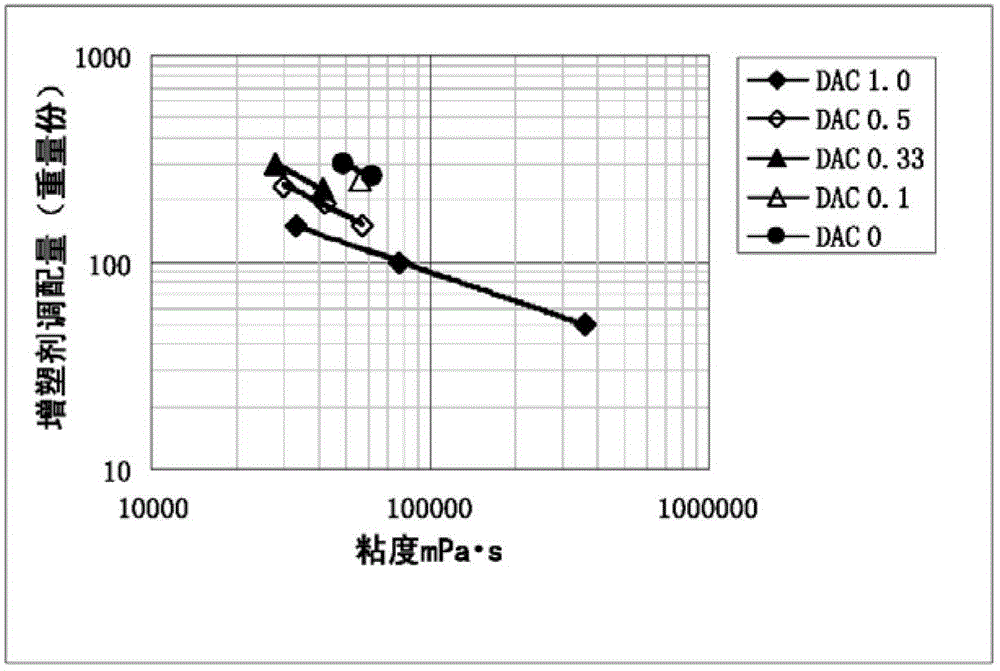

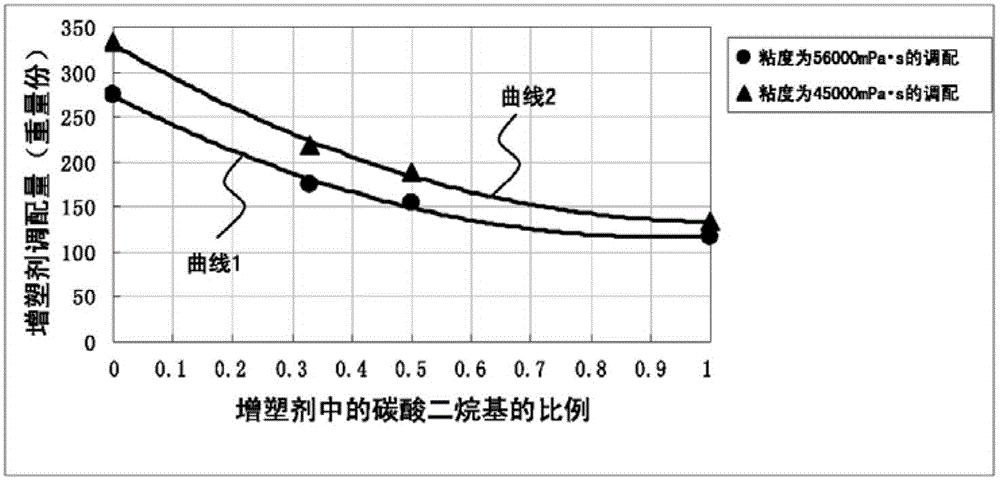

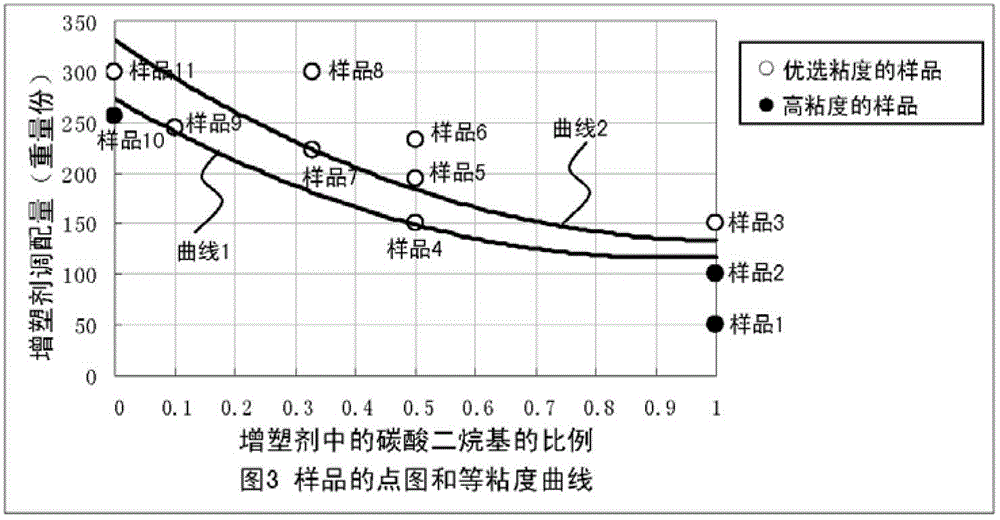

[0033] The thermally conductive molded article of the present invention is a polymer substrate composed of an olefin-based liquid resin, a plasticizer containing a specific proportion of dialkyl carbonate (Dialkyl) and a non-silicone-based oil with a flash point of 250°C or higher, A hardened body formed after hardening of a liquid mixed composition composed of a thermally conductive filler. The composition of the above materials will be described below.

[0034] Polymer substrate: Olefin-based liquid resin is used for the polymer substrate. Since the olefin-based liquid resin is a non-silicone-based polymer, contact failure due to low-molecular-weight siloxane does not occur. In addition, olefin-based liquid resins have excellent defoaming performance even in the production process of mixing thermally conductive fillers with non-silicone-based polymers, and can be adjusted to curable materials that have a relatively long pot life. Furthermore, it can also have the heat resi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ignition point | aaaaa | aaaaa |

| ignition point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com