Release film

A release film and release technology, applied in electronic equipment, applications, coatings, etc., can solve the problem of difficult to find polarizers, their missed inspections, etc., to improve the accuracy of foreign matter inspection, less bright spots, and high industrial value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

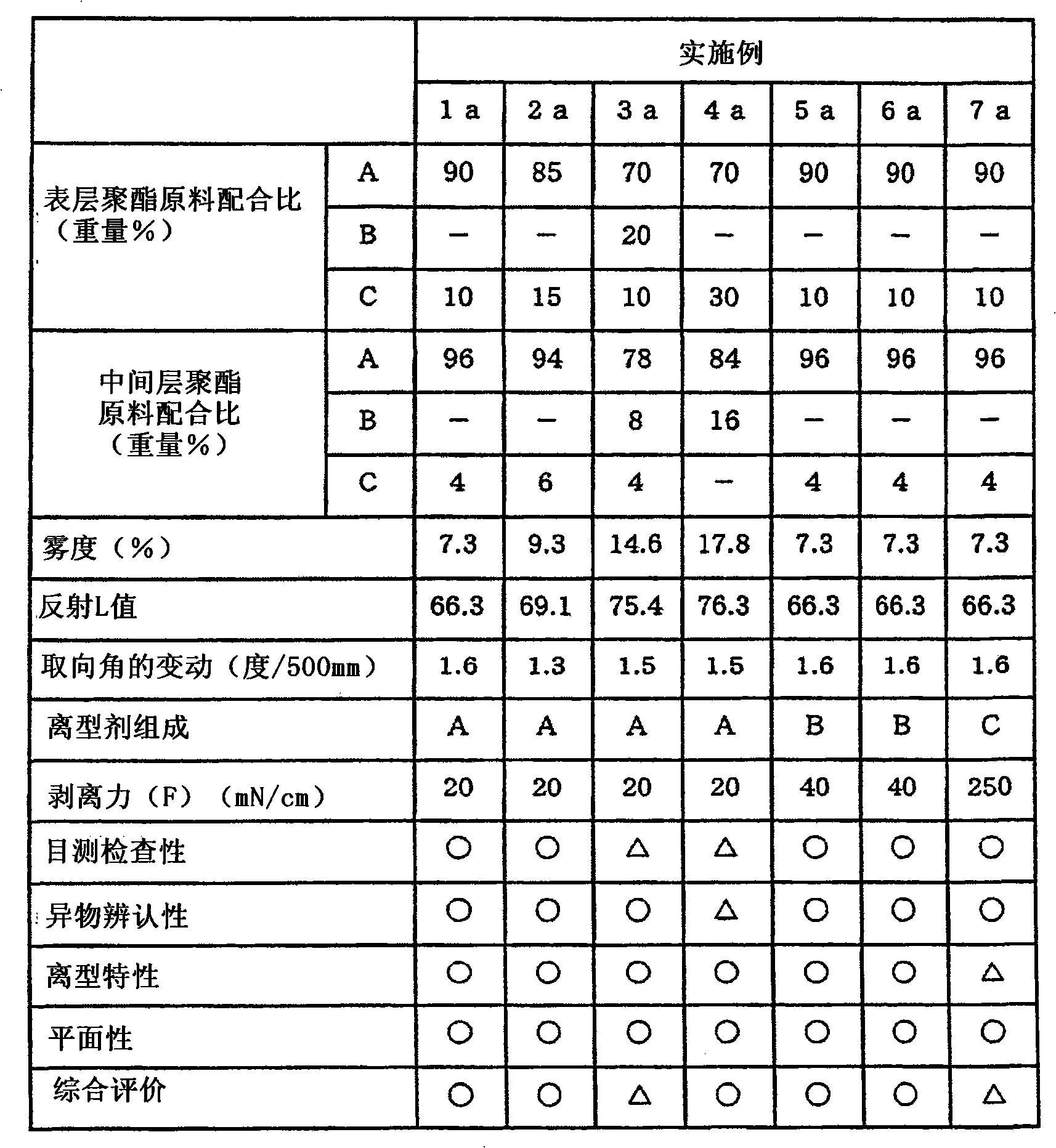

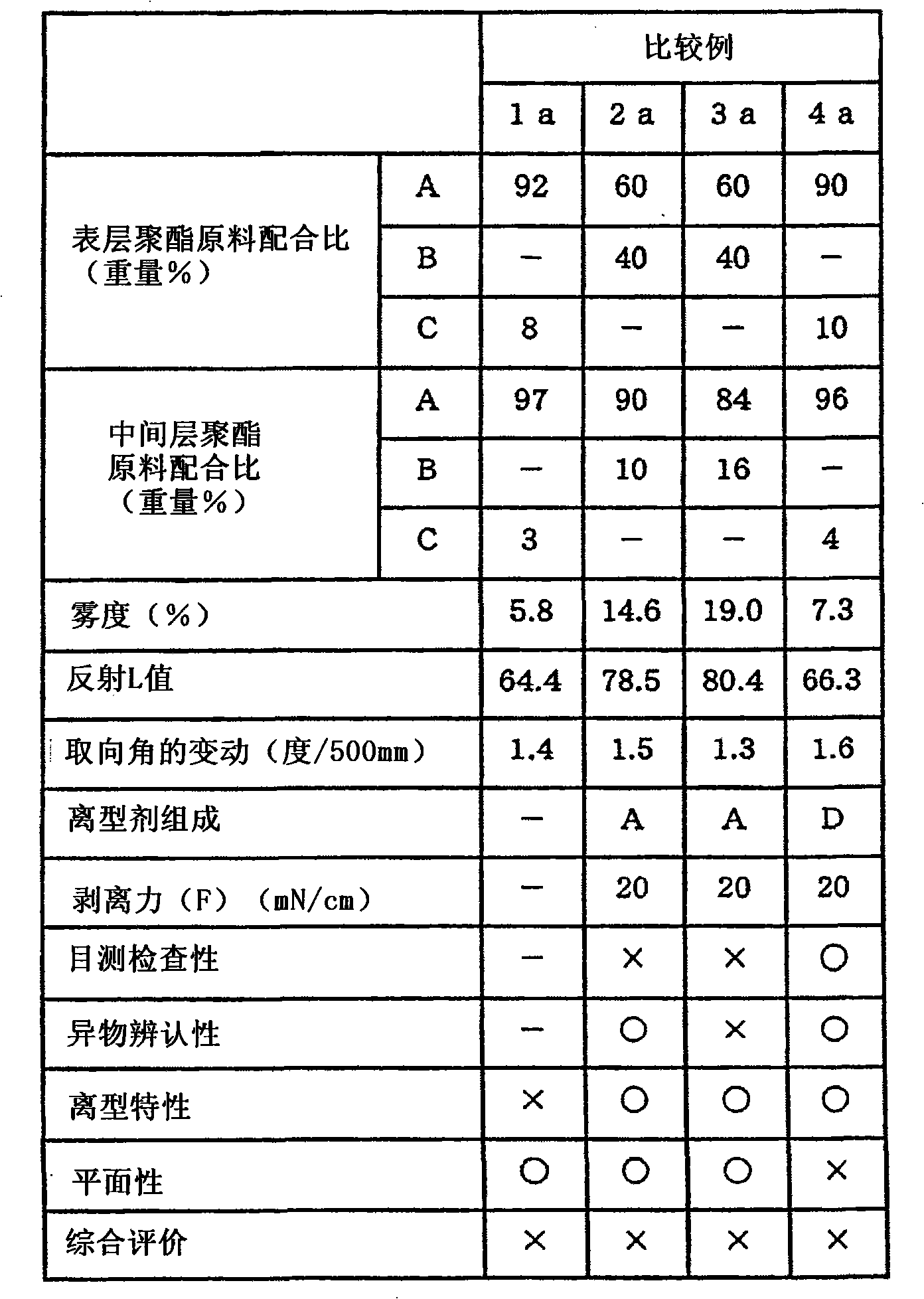

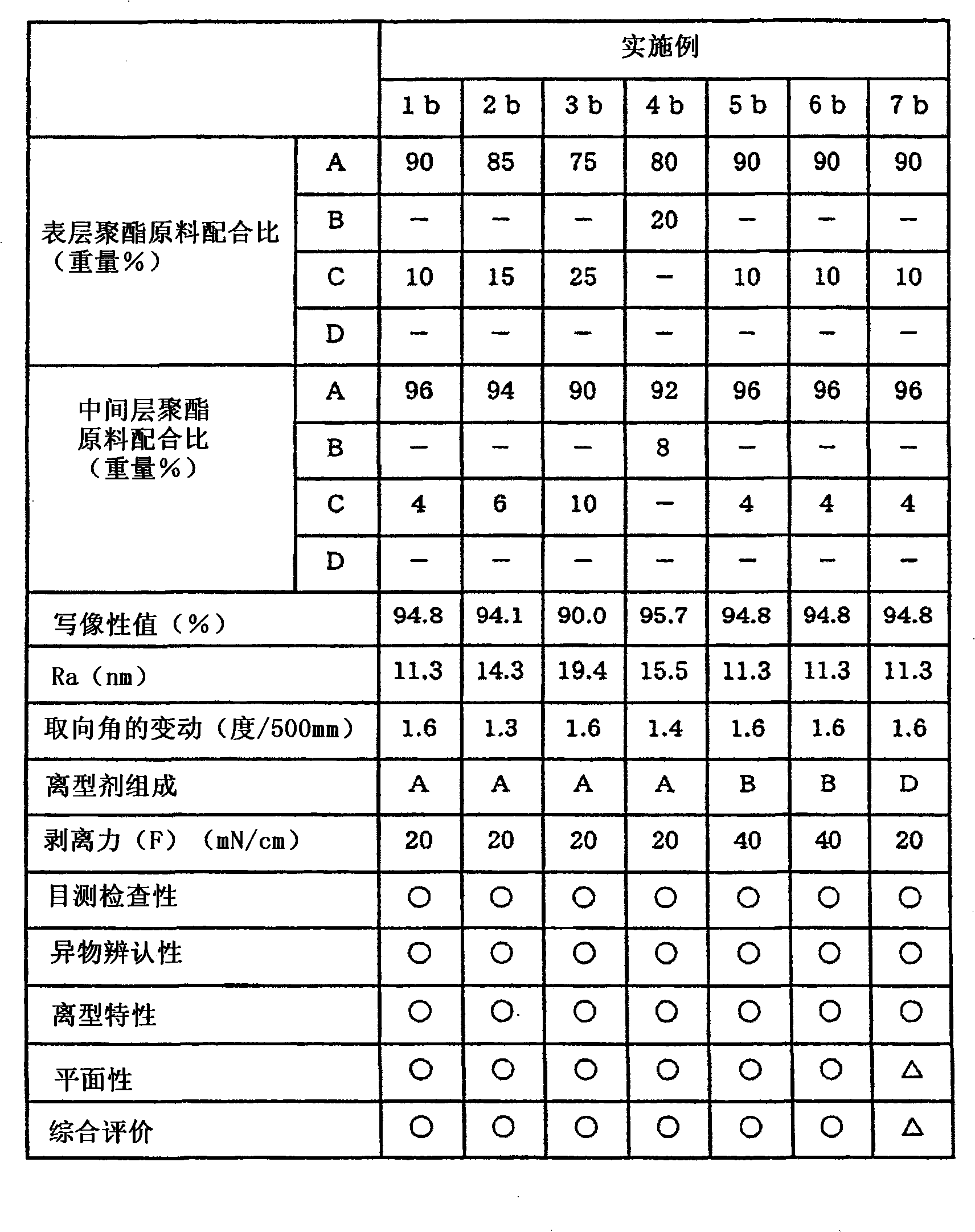

Embodiment

[0056] Hereinafter, the present invention will be described in more detail using examples, but the present invention is not limited to the following examples unless the gist thereof is exceeded. However, "parts" in Examples and Comparative Examples means "parts by weight". In addition, the measuring method used in this invention is as follows.

[0057] (1) Determination of intrinsic viscosity of polyester

[0058] 1 g of polyester was accurately weighed, dissolved in 100 ml of a mixed solvent of phenol / tetrachloroethane=50 / 50 (weight ratio), and measured at 30°C.

[0059] (2) Average particle size (d50)

[0060] The particle diameter at which the cumulative volume percentage is 50% in the equivalent spherical distribution measured using a centrifugal sedimentation type particle size distribution analyzer (SA-CP3 type) manufactured by Shimadzu Corporation was defined as the average particle diameter d50.

[0061] (3) Measurement of variation of orientation angle in film (deg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com