Gas nitriding process of 00Ni18Co8Mo5AlTi high-strength maraging steel

A technology of maraging steel and gas nitriding, which is applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve the problem that the nitriding layer cannot be formed, the gas nitriding process is still blank, and the activity is hindered. Nitrogen atom infiltration and other problems can achieve the effects of small distortion, improved wear resistance and fatigue resistance, and excellent strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

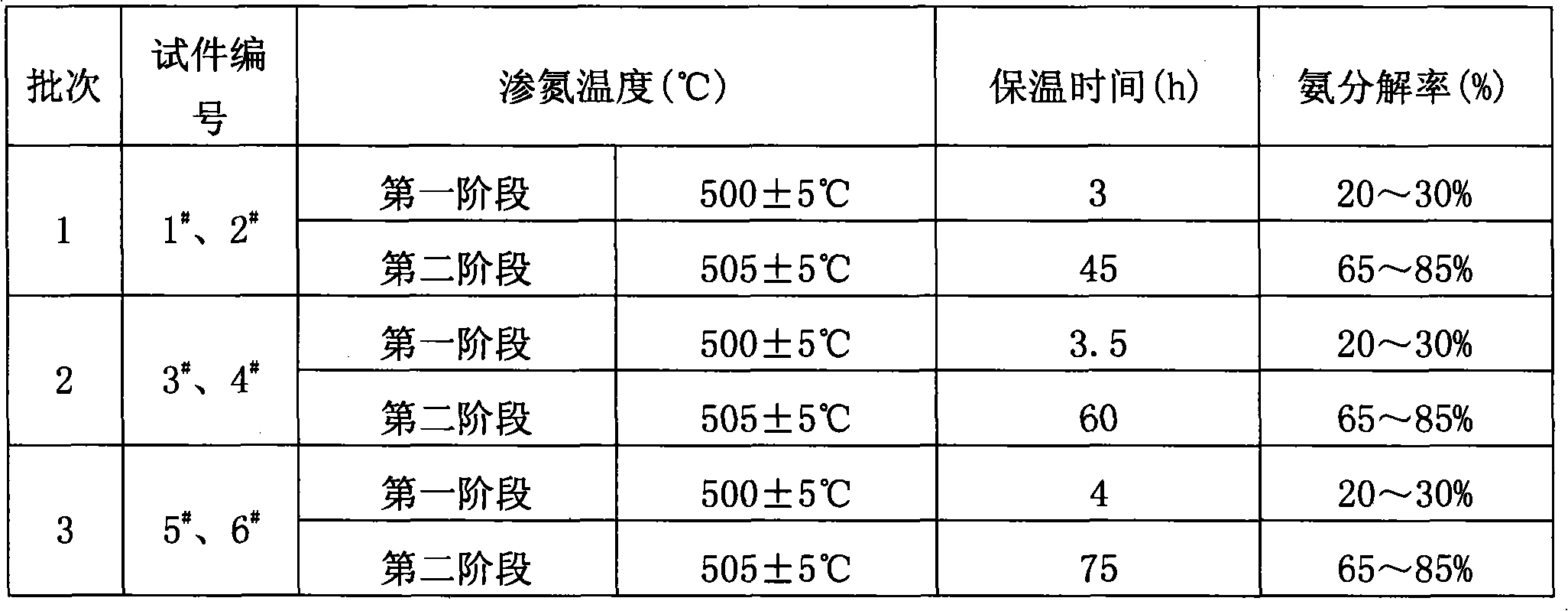

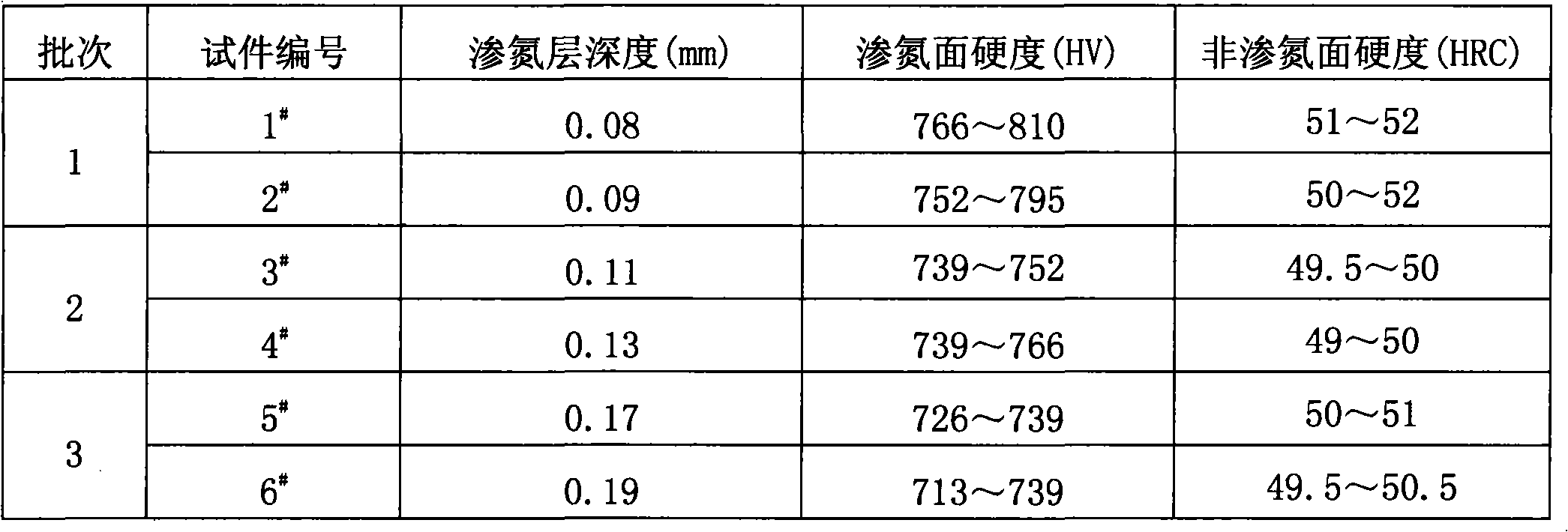

[0022] A gas nitriding process for 00Ni18Co8Mo5AlTi high-strength maraging steel according to the present invention, the gears whose material is 00Ni18Co8Mo5AlTi are carried out nitriding treatment, during production, according to each batch of 20 gears, a total of 3 batches are respectively carried out nitriding Nitrogen treatment:

[0023] 1. Receive the steel rod (φ35mm×200mm) of the same purchase batch and the material is 00Ni18Co8Mo5AlTi, and perform solid solution treatment:

[0024] Heating equipment: box-type resistance furnace Heating temperature: 820±10°C

[0025] Heat preservation time: 70-90 minutes Cooling method: air cooling

[0026] 2. Process all the gears to the finished product size, and take another material that has undergone solid solution, and process 2 heat treatment test pieces for furnace nitriding in each batch. The size of the test pieces is: φ32mm×φ15mm×10mm (outer diameter × inner diameter × height).

[0027] 3. Prepare the heating equipment and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com