Lead-free electronic silver paste and preparation method thereof

A technology of lead electronics and silver paste, which is applied in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, circuits, etc., can solve the problems of large environmental pollution and poor solderability, and achieve simple preparation process and sticky Good adhesion and improved solderability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

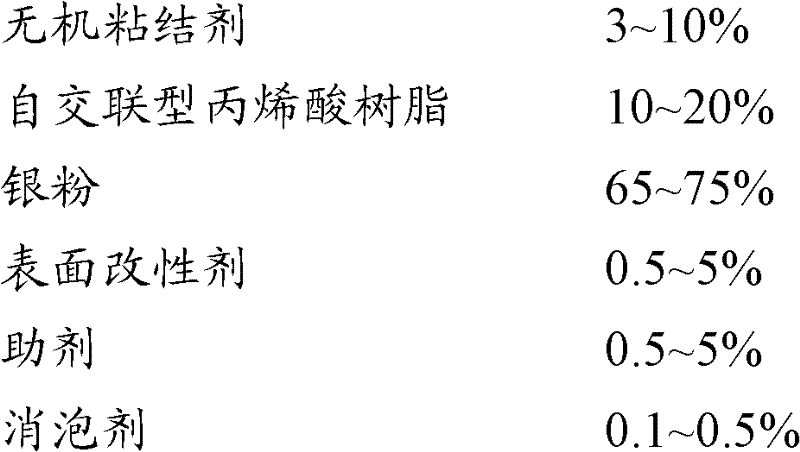

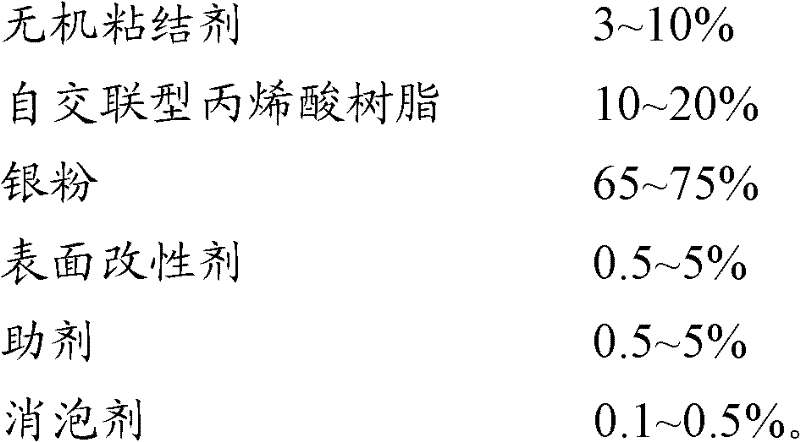

Method used

Image

Examples

Embodiment 1

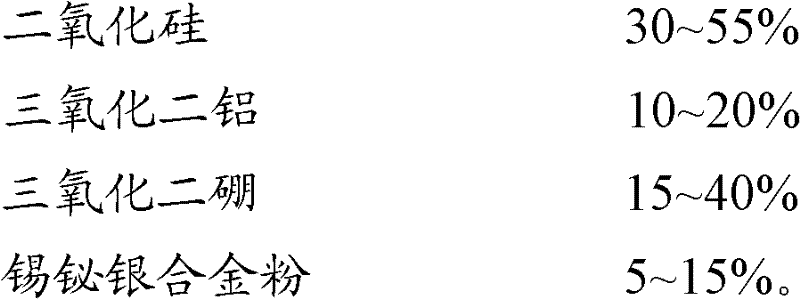

[0034] First, add the mass of SiO to the V-shaped mixer respectively: 2 30.0g, Al 2 o 3 15.0g, B 2 o 3 40.0g, and 15.0g of tin-bismuth-silver alloy powder (Sn63Bi36.7Ag0.3), mix well; then put the mixed material in a crucible, heat in a muffle furnace at 1000°C for 3h; take out the molten material and pour it into Quenching in cold water, putting it into a ball mill and milling for 3 hours until the average fineness is 12-14 μm, and then the lead-free inorganic binder is obtained after discharging and drying, which is ready for use.

[0035] Add 40.0g of diethylene glycol butyl ether to a reactor equipped with a condenser, start the agitator and heat for standby; then add 36.0g of methyl methacrylate, 5.0g of isooctyl acrylate, 15.0g of methyl Add glycidyl acrylate and 3.8g of N-methylolacrylamide into the mixing kettle, add 0.2g of benzoyl peroxide and stir evenly, and set aside; Add the above mixed monomers dropwise into the kettle, control all the mixed monomers to be ...

Embodiment 2

[0038] First, add the mass percentage in the V-type mixer as follows: SiO 2 45g, Al 2 o 3 10g, B 2 o 335g, and 10g of tin-bismuth-silver alloy powder (Sn63Bi36.7Ag0.3), mix well; then put the mixed material in a crucible, heat it in a muffle furnace at 1100°C for 2 hours; take out the molten material and quickly pour it into cold water Quenching, putting into a ball mill and ball milling for 4 hours until the average fineness is 10-12 μm, and the lead-free inorganic binder is obtained after discharging and drying, which is ready for use.

[0039] Add 84g of diethylene glycol ethyl ether acetate in a reactor equipped with a condenser, start the agitator and heat it for standby; then add 5.5g of ethyl acrylate, 6g of butyl acrylate, and 4.4g of glycidyl methacrylate into the mixing tank Add 0.1g of azobisisobutyronitrile, stir evenly, and set aside; when the diethylene glycol ethyl ether acetate in the reaction kettle is heated to 85°C, add the above mixed monomers dropwise ...

Embodiment 3

[0042] First, add the mass percentage in the V-type mixer as follows: SiO 2 50g,Al 2 o 3 20g, B 2 o 3 25g, and 5g of tin-bismuth-silver alloy powder (Sn63Bi36.7Ag0.3), mix well; then put the mixed material in a crucible, heat it in a muffle furnace at 1200°C for 2 hours; take out the molten material and pour it into cold water quickly Quenching, putting into a ball mill and ball milling for 5 hours until the average fineness is 3-5 μm, and the lead-free inorganic binder can be obtained after discharging and drying, which is ready for use.

[0043] Add 25.0g of diethylene glycol dibutyl ether, 25.0g of diethylene glycol methyl ether acetate in the reactor with condenser, start the stirrer and heat for standby; then 28.0g of methyl methacrylate, 5.0 g of ethyl acrylate, 5.0 g of isooctyl acrylate, 9.5 g of glycidyl methacrylate, 1.0 g of N-methylol acrylamide, and 1.0 g of hydroxypropyl acrylate were added to the mixing tank, and 0.5 g Stir the benzoyl peroxide evenly and s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com