Low-carbon bainitic cold-work-strengthened non-quenched and tempered steel with excellent delayed fracture resistance

A delayed fracture resistance and bainite type technology, applied in the field of alloy steel, can solve the problems of high cold workability, deterioration of cold workability, lack of movable dislocation suppression, etc., and achieve good plasticity and cold workability, excellent delayed fracture resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

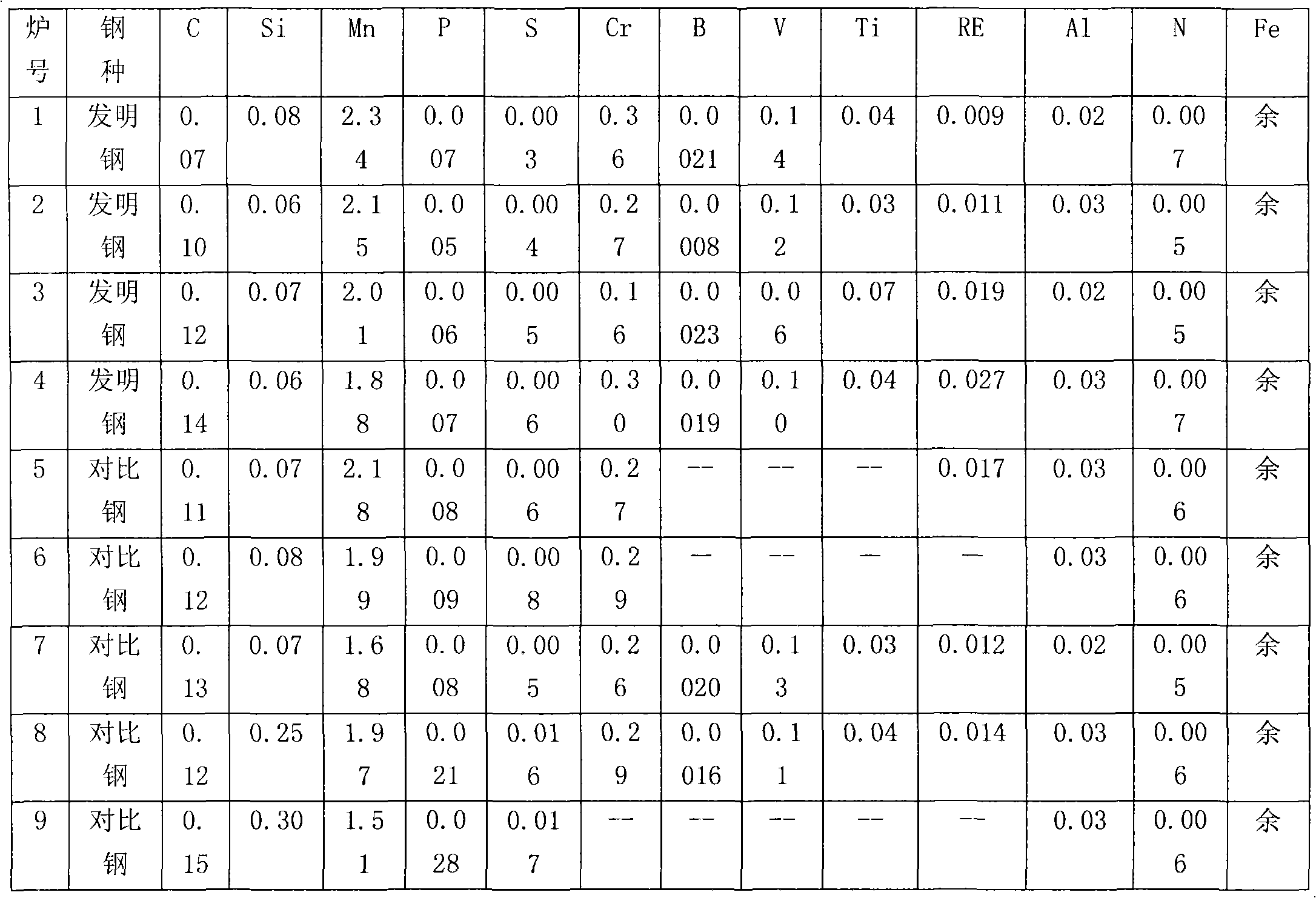

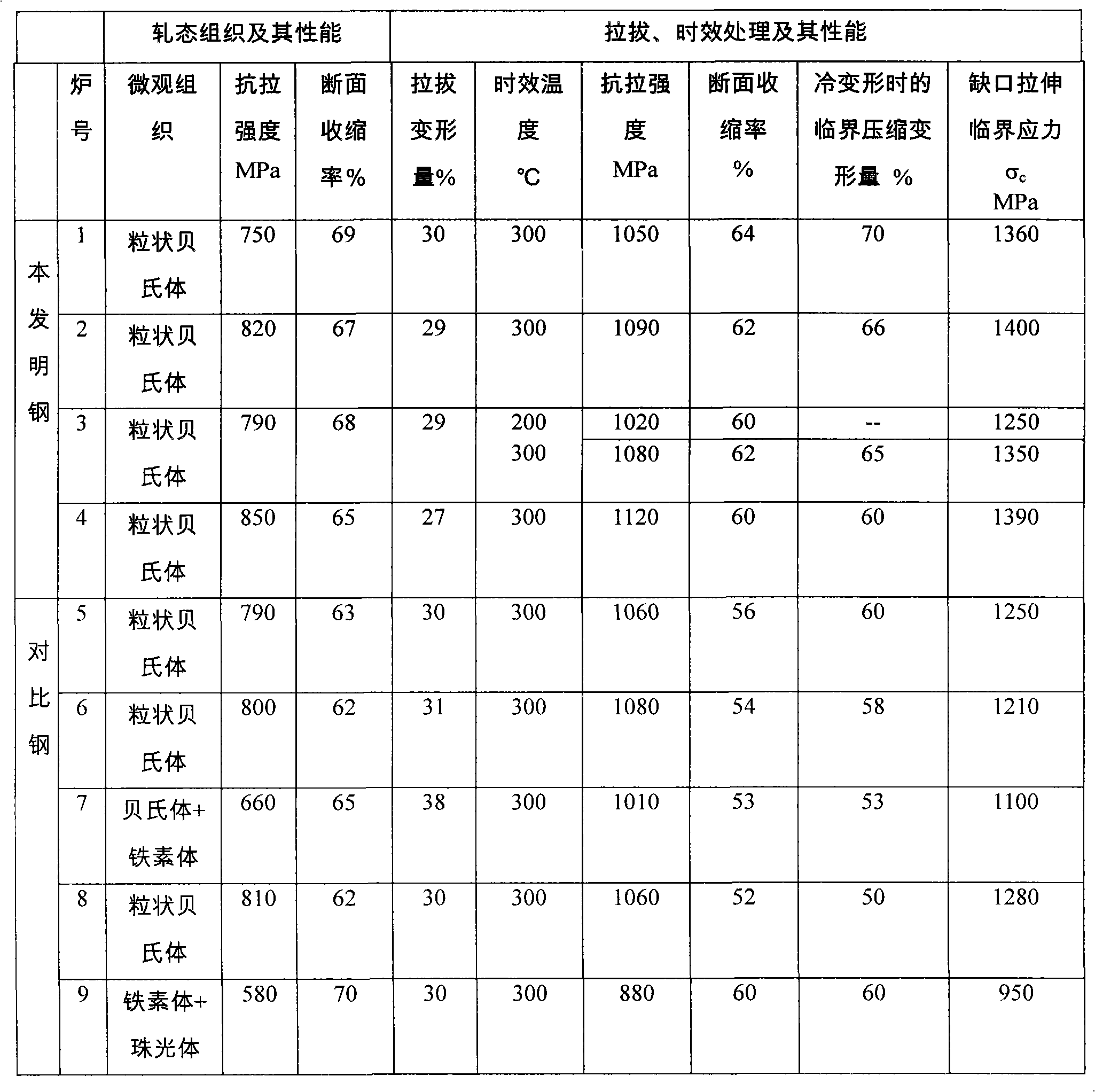

[0024] According to the chemical composition range designed above, 4 furnaces of the steel of the present invention and 5 furnaces of comparative steel were smelted on a 50 kg vacuum induction furnace, and their specific chemical compositions are shown in Table 1. Among them, furnace numbers 1-4# are the steels of the present invention, and furnace numbers 5-9# are comparative steels. Molten steel is cast into ingots and forged into rods. Some rods are then drawn with different area reduction ratios and subjected to aging treatment. Sampling and processing into standard room temperature tensile specimens (l 0 =5d 0 , d 0 =5mm), notched tensile delayed fracture specimen (diameter d=5mm, d at the notch N =3mm, notch 60°±2° / 0.15R±0.025) and cold deformed sample (diameter d=10mm, height h=20mm).

[0025] The samples were subjected to tensile, impact, notched tensile delayed fracture and cold deformation tests at room temperature. The solution for the delayed fracture test is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com