High-strength cold-rolled steel sheet and manufacturing method therefor

A technology of cold-rolled steel sheet and manufacturing method, which is applied in the field of high-strength cold-rolled steel sheet and its manufacture, can solve the problem of reduced reactivity between steel sheet and chemical conversion treatment solution, and achieves good chemical conversion treatment property, stable manufacturing, and excellent corrosion resistance. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

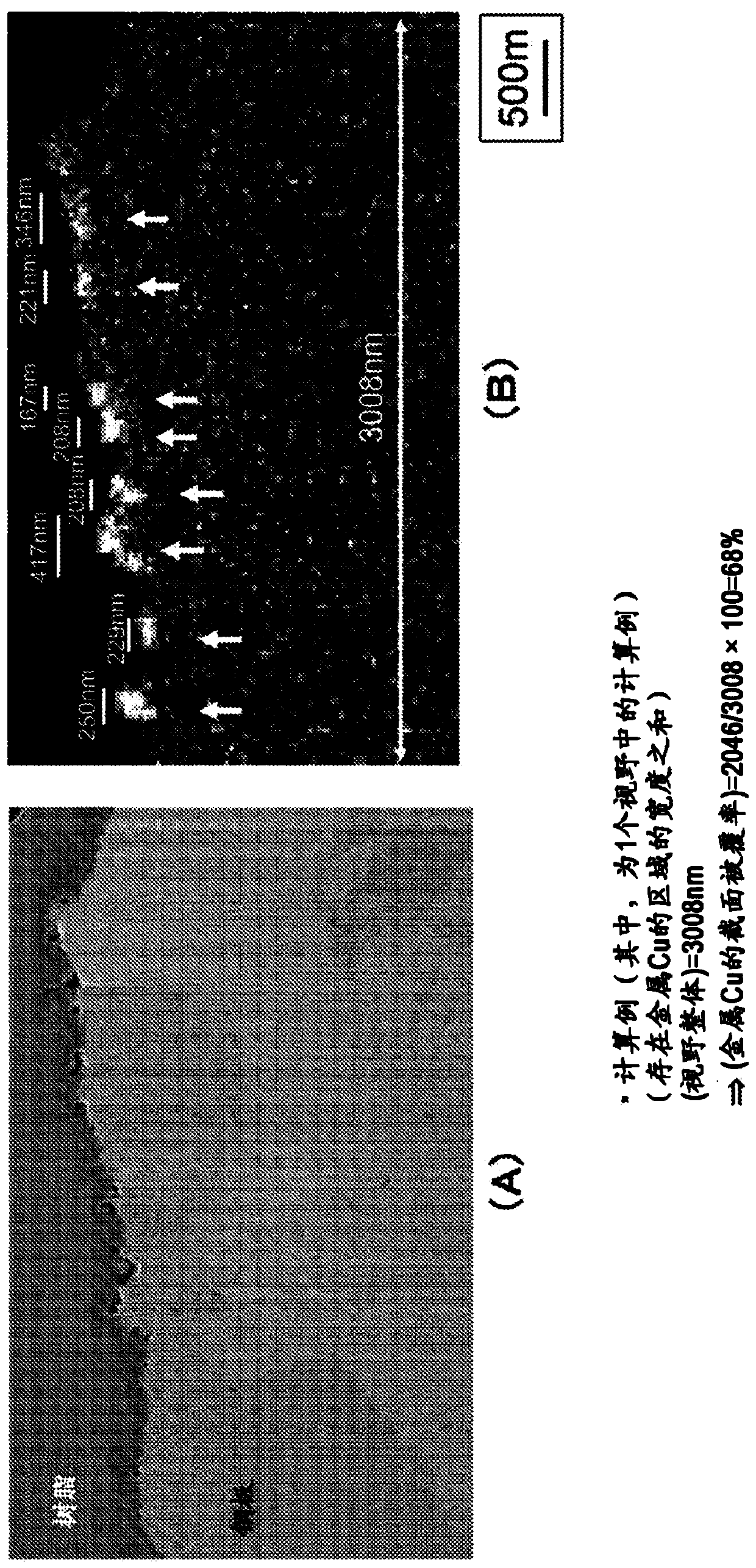

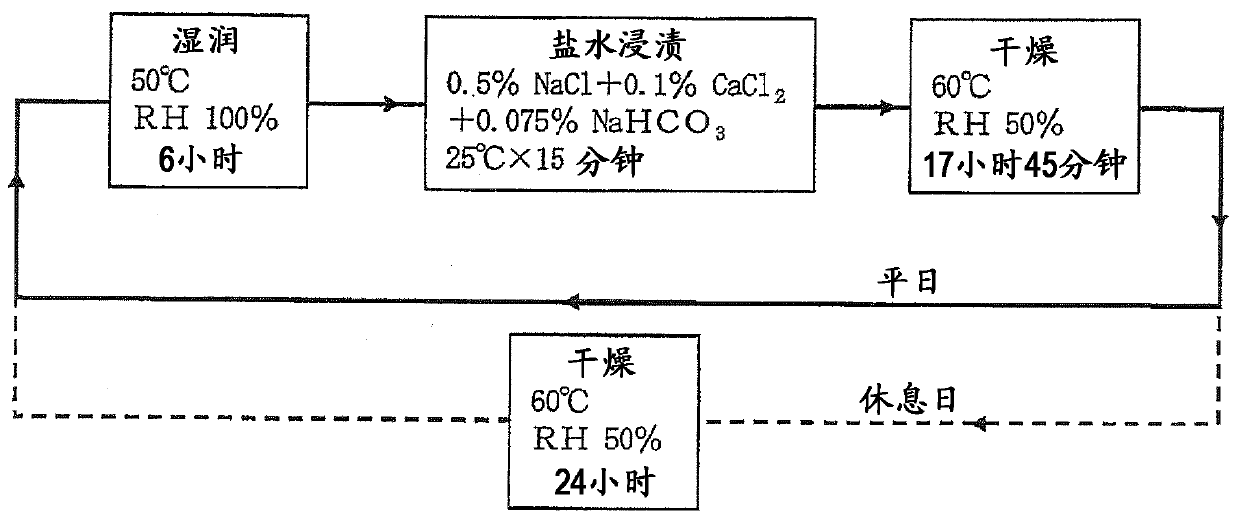

[0082] As the test material, a continuous annealing material (cold-rolled steel sheet) having the component composition and tensile strength TS shown in Table 1 was used. These steel sheets were pickled, washed with water, and dried under the conditions shown in Table 2 and Table 3, and then subjected to temper rolling with an elongation of 0.7% to produce high-strength cold-rolled steel sheets No. 1 to 33. It should be noted that the Fe of the pickling solution 3+ The ion concentration is adjusted by the method described above.

[0083] A test piece was collected from each manufactured steel plate, and 5 locations on the surface of the test piece selected arbitrarily were analyzed in the depth direction by glow discharge emission spectroscopy (GDS), and it was investigated whether Al, Si, Mn, and O were displayed. The peaks of Al, Si, Mn, and O are evaluated as "existence (remaining) of oxide layer", and the cases where none of the peaks appear are evaluated as "absence" (Remai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com