High strength cold rolled steel plate

A cold-rolled steel plate, high-strength technology, applied in the direction of metal material coating process, etc., can solve the problem of inability to suppress delayed fracture, and achieve the effects of excellent temporary rust resistance, delayed fracture inhibition, and weight reduction

Active Publication Date: 2021-07-13

JFE STEEL CORP

View PDF15 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, when such a method is used, the amount of hydrogen infiltrated into the steel sheet from the external environment does not change, and even if delayed fracture can be delayed, delayed fracture itself cannot be suppressed.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

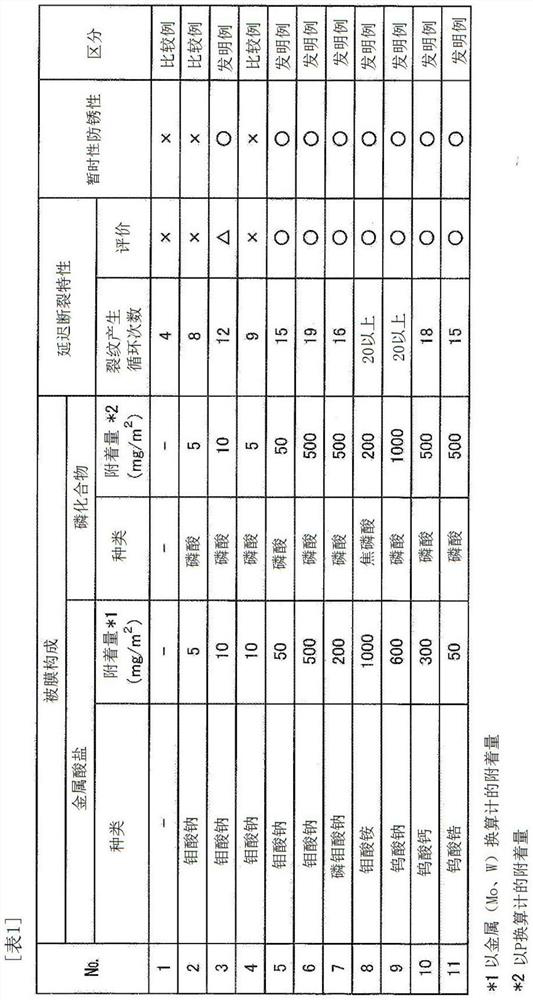

[0039] As the billet steel sheet, a cold-rolled steel sheet having a tensile strength of 1520 MPa and a sheet thickness of 1.5 mm (a steel sheet in a cold-rolled state) having the following components: C: 0.191 mass%, Si: 0.4 mass%, Mn: 1.56 mass%, P: 0.011 mass%, S: 0.001 mass%, the balance of Fe and inevitable impurities.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Login to View More

Abstract

The present invention provides a steel plate suitable mainly for strength parts for automobiles and building materials, the steel plate has a tensile strength of 1180 MPa or more, is excellent in delayed fracture resistance, and is also excellent in temporary rust resistance. It has a film on the surface of a cold-rolled steel sheet with a tensile strength of 1180 MPa or more, and the film contains one or more metal salts and phosphorus compounds selected from molybdate and tungstate, and the metal salt is a metal (Mo, W) conversion calculated the total adhesion amount is 10 ~ 1000mg / m 2 , preferably 50-1000mg / m 2 , the attachment amount of phosphorus compound in P conversion is 10~1000mg / m 2 .

Description

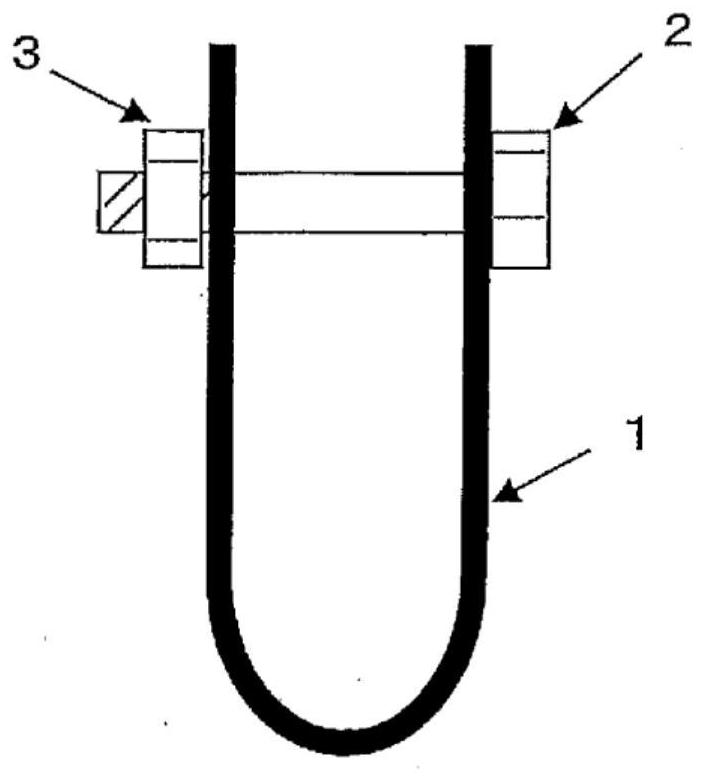

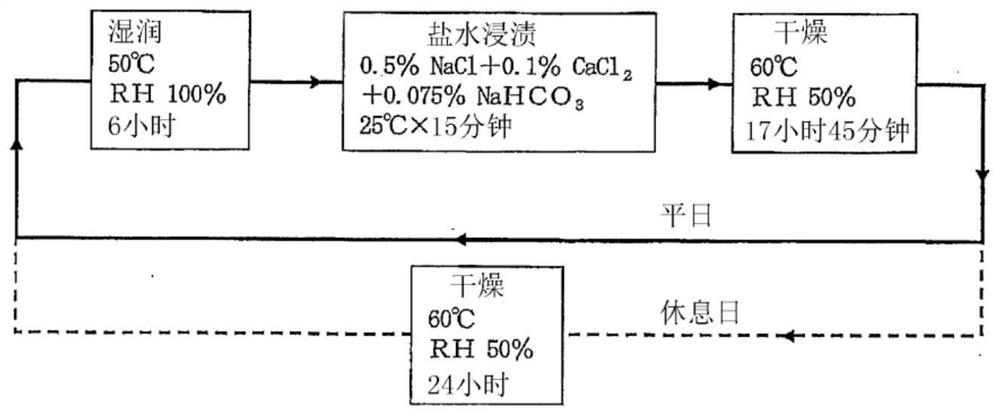

technical field [0001] The present invention relates to a steel sheet excellent in delayed fracture resistance. In detail, it relates to a steel plate mainly suitable for strength parts for automobiles and building materials, which is a kind of steel plate that requires delayed fracture resistance and has a tensile strength of 1180MPa (about 120kgf / mm) 2 ) or higher high-tensile steel sheets. Background technique [0002] Conventionally, cold-rolled steel sheets have been used as steel sheets for automobiles due to the requirement of thickness accuracy and flatness, but in recent years, the reduction of CO emissions from automobiles has 2 From the viewpoint of emission and safety, we are constantly researching the strengthening of steel sheets for automobiles. [0003] However, it is known that when the strength of the steel material is increased, delayed fracture tends to occur, and this phenomenon becomes apparent as the strength increases, especially in high-strength st...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C23C22/06C22C38/00C22C38/04

CPCC22C38/00C22C38/04C23C22/42C23C22/74C23C22/40C22C38/002C22C38/02

Inventor 土本和明大塚真司秦谦太郎松崎晃

Owner JFE STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com