High-strength hot-dip zinc-coated steel sheet and method for manufacturing same

A hot-dip galvanized steel sheet, hot-dip galvanized technology, applied in hot-dip galvanizing process, manufacturing tools, chemical instruments and methods, etc., can solve the problems of high strength resistance, delayed fracture, etc., and achieve excellent delayed fracture resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

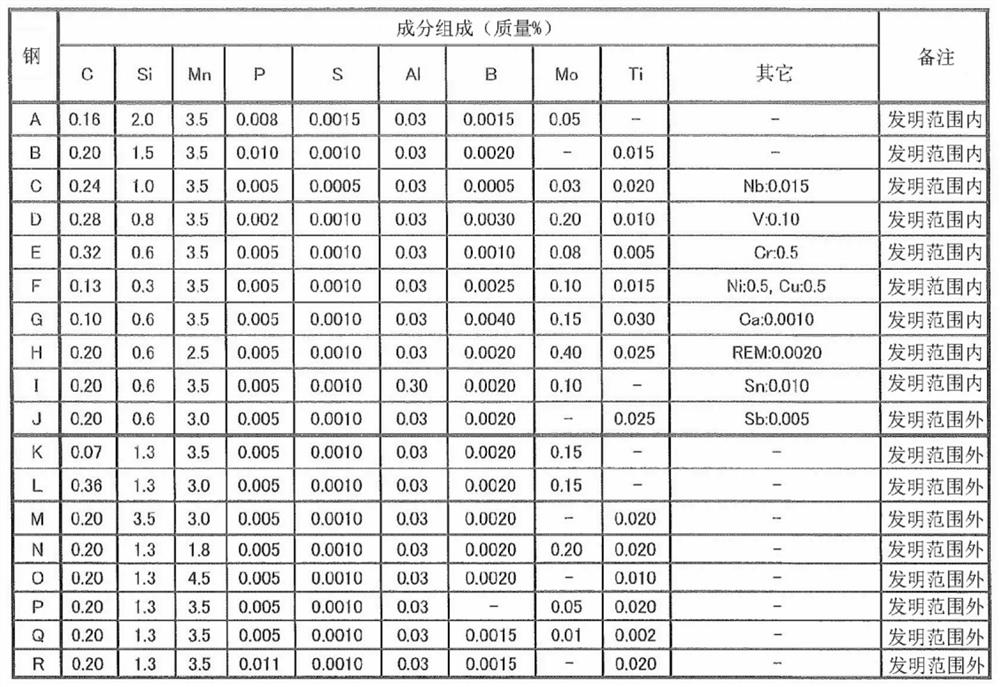

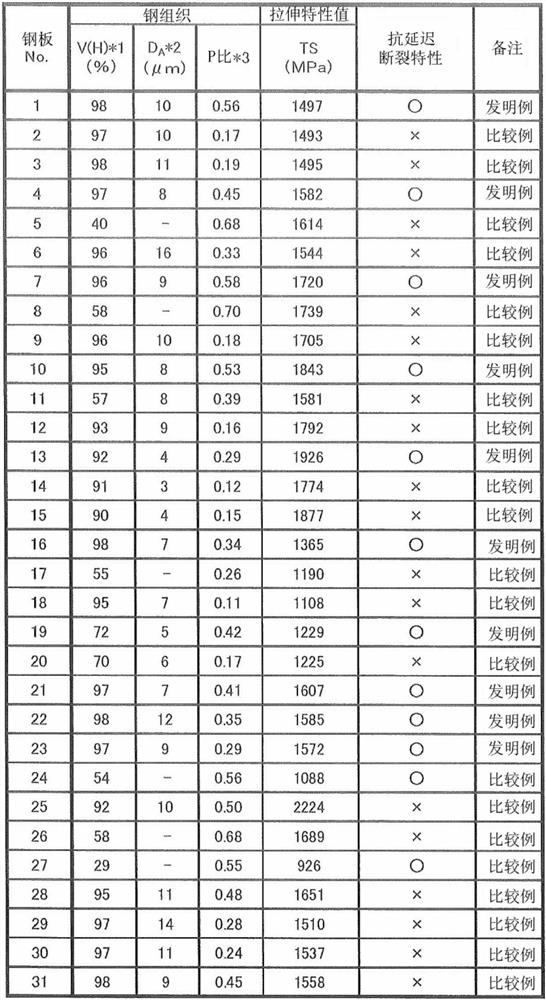

[0094] Hereinafter, the present invention will be specifically described based on examples. The steel (the remainder is Fe and unavoidable impurities) is melted and rolled in a vacuum melting furnace in the laboratory to make a steel billet. The component composition of the steel is shown in Table 1.

[0095] [Table 1]

[0096]

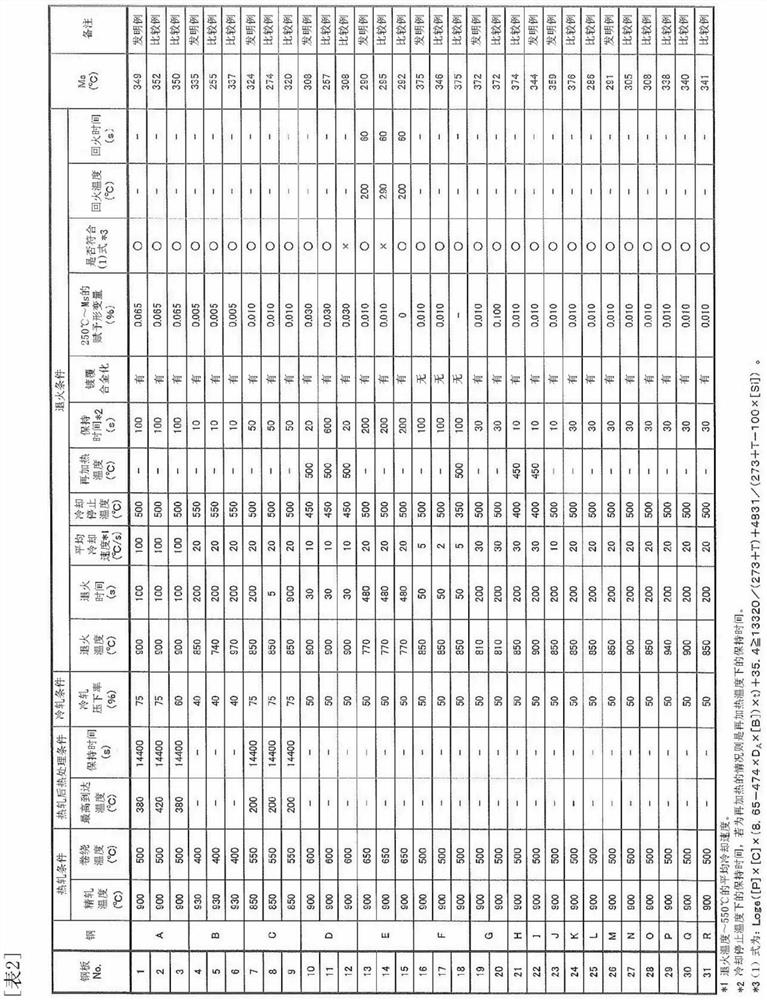

[0097] These billet materials were heated to 1250° C., rough rolling and hot rolling were performed, and heat treatment of hot-rolled sheets was performed. Next, it was cold-rolled to 1.4 mm to produce a cold-rolled sheet. The obtained cold-rolled sheet was subjected to annealing. In the annealing, a heat treatment and coating treatment apparatus was used in a laboratory to produce galvanized steel sheets (GI) and galvanized steel sheets (GA) 1 to 31. The hot-dip galvanized steel sheet is dipped in a coating bath at 465°C, and the adhesion amount of each single side is 40-60g / m on both sides of the steel sheet. 2 Made of plating layer. The al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com