High titanium hydrochloric acid leaching slag, new application thereof and preparation method of titanium pigment

A high-titanium hydrochloric acid and hydrochloric acid leaching technology, which is applied in the direction of chemical instruments and methods, titanium compounds, titanium dioxide, etc., can solve the problems of hydrochloric acid leaching method particle size refinement, etc., to reduce the number of washing times, reduce the production of ferrous sulfate, and reduce emissions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

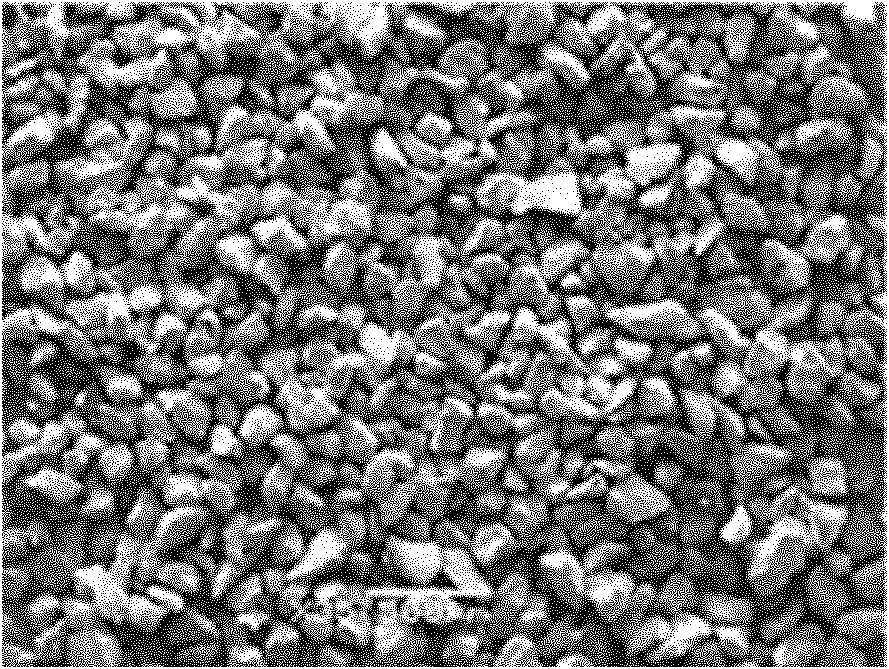

[0042] Example 1 Preparation of high titanium hydrochloric acid leaching residue by directly leaching ilmenite with hydrochloric acid

[0043] 1. Measure 45 liters of 20% hydrochloric acid and pour it into a 50 liter enamel-lined reaction tank;

[0044] 2. Weigh 15 kg of titanium concentrate, pour it into the reaction tank, seal it, and start the agitator;

[0045] 3. Rapid heating to about 140°C;

[0046] After 4.5 hours, stop heating and cool down to 80°C naturally;

[0047] 5. Rapidly filter the materials in the 3-liter reaction tank. Filtration is formed by connecting a Buchner flask to a vacuum pump;

[0048] 6. Wash the filter cake three times with 3 liters of deionized water. Dry at 110°C for 6 hours to obtain high titanium hydrochloric acid leaching residue. The water content of the obtained leaching residue is less than 1%.

[0049] The chemical composition of the high titanium hydrochloric acid leaching residue was analyzed, and the results are shown in Table 1...

Embodiment 2

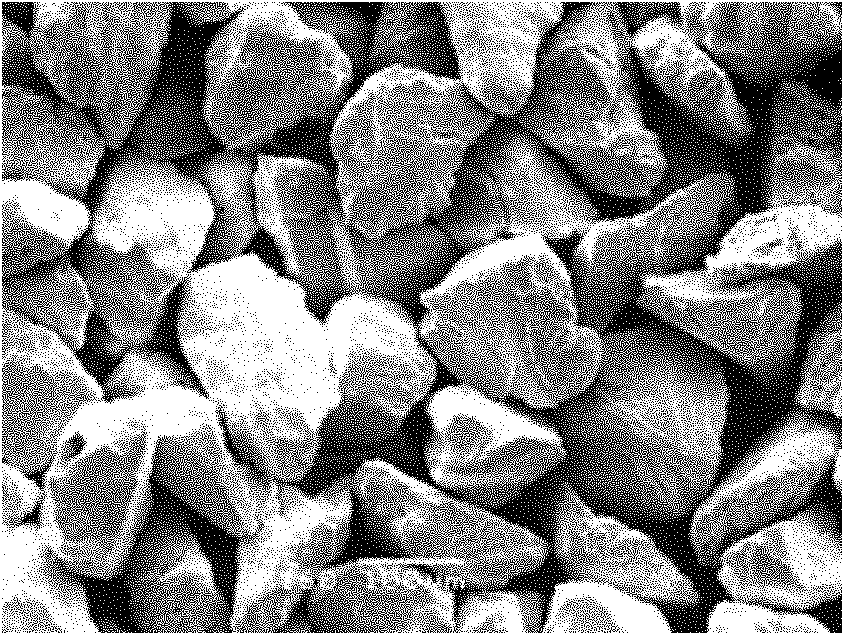

[0052] Example 2 Preparation of high titanium hydrochloric acid leaching slag by directly leaching titanium concentrate with hydrochloric acid

[0053] 1. Measure 45 liters of 20% hydrochloric acid and pour it into a 50 liter enamel-lined reaction tank.

[0054] 2. Weigh 15 kg of titanium concentrate, pour it into the reaction tank, seal it, and start the agitator.

[0055] 3. Rapidly heat to about 120°C.

[0056] After 4 or 5 hours, stop heating and cool naturally to 80°C.

[0057] 5. Rapidly filter the materials in the 3-liter reaction tank. Filtration is accomplished through a Buchner flask connected to a vacuum pump.

[0058] 6. Wash the filter cake three times with 3 liters of deionized water. Dry at 110°C for 6 hours to obtain high titanium hydrochloric acid leaching residue. The water content of the obtained leaching residue is <1%.

[0059] The chemical composition of the high titanium hydrochloric acid leaching residue was analyzed, and the results are shown in ...

Embodiment 3

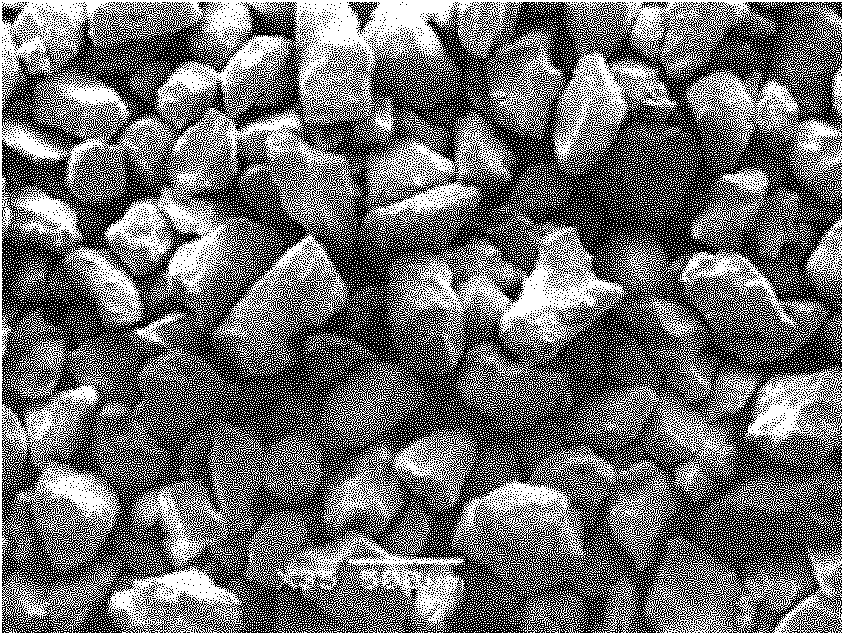

[0062] Example 3 Preparation of high titanium hydrochloric acid leaching slag by directly leaching titanium concentrate with hydrochloric acid

[0063] 1. Measure 45 liters of 20% hydrochloric acid and pour it into a 50 liter enamel-lined reaction tank.

[0064] 2. Weigh 15 kg of titanium concentrate, pour it into the reaction tank, seal it, and start the agitator.

[0065] 3. Rapidly heat to about 130°C. After 7 hours, the heating was stopped, and it was naturally cooled to 80°C.

[0066] 4. The materials in the reaction tank are rapidly filtered batch by batch. The filtration device is formed by connecting a Buchner flask with a vacuum pump.

[0067] 5. Wash the filter cake three times with 3 liters of tap water for each filtration. Dry at 110° C. for 6 hours to obtain high titanium hydrochloric acid leaching residue. The water content of the obtained leaching residue is <1%.

[0068] The chemical composition of the high titanium hydrochloric acid leaching residue was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com