Method for preparing gold nanoparticles

A nano-gold and particle technology, which is applied in the field of preparation of nano-gold particles, can solve problems such as long technical time, shortened preparation cycle, and product stability to be improved, so as to reduce adverse effects, accurately control particle size distribution, and heat evenly and quickly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

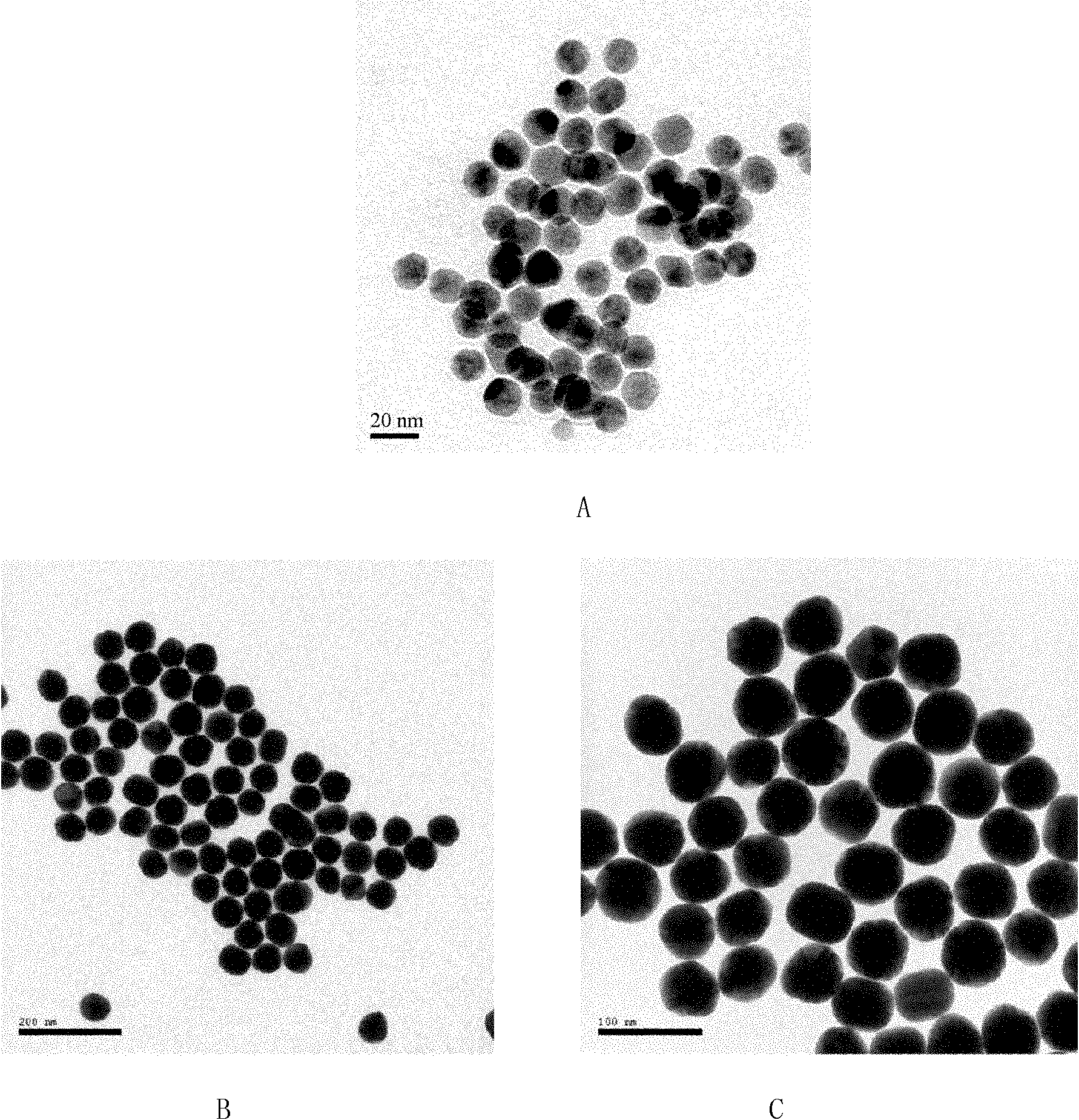

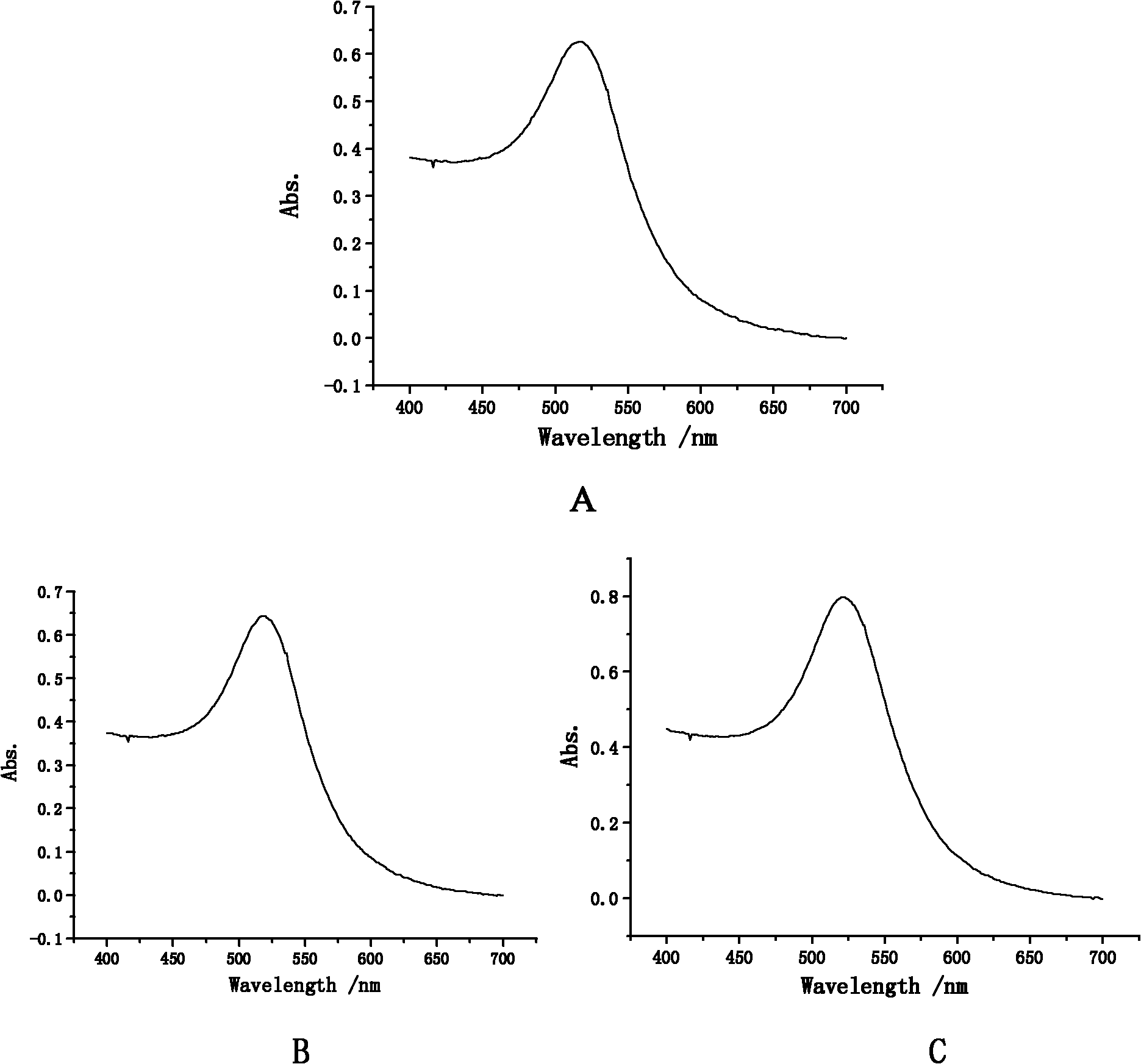

Embodiment 1

[0025] Add 100 mL of chloroauric acid solution with a concentration of 100 μg / mL into a three-neck flask, add 10 mL of polyvinylpyrrolidone solution, and 10 mL of polyethylene glycol solution. Put the three-neck flask into a microwave reactor for reaction, set the microwave power to 650W, and the solution boils after 1.5 minutes. Quickly add 2 mL of sodium citrate solution with a concentration of 0.02 g / mL, continue the microwave reaction under stirring at 300 r / min, the microwave power is 325 W, and stop the reaction after 5 minutes. After the reaction was completed, 10 mL of cetyltrimethylammonium bromide solution was added to terminate the reaction. Finally, the reaction solution was centrifuged at a low speed of 1000r / min by a high-speed centrifuge, and the supernatant was then centrifuged at a high speed of 11000r / min, and the lower sediment was washed with twice distilled water to obtain a product with a particle size of 15nm.

Embodiment 2

[0027] Add 100 mL of chloroauric acid solution with a concentration of 100 μg / mL into a three-neck flask, add 10 mL of polyvinylpyrrolidone solution, and 10 mL of polyethylene glycol solution. Put the three-neck flask into a microwave reactor for reaction, set the microwave power to 650W, and the solution boils after 1.5 minutes. Quickly add 4 mL of sodium citrate solution with a concentration of 0.02 g / mL, continue the microwave reaction under stirring at 200 r / min, the microwave power is 390 W, and stop the reaction after 6 minutes. After the reaction was completed, 10 mL of cetyltrimethylammonium bromide solution was added to terminate the reaction. Finally, the reaction solution was centrifuged at a low speed of 1000r / min by a high-speed centrifuge, and the supernatant was then centrifuged at a high speed of 11000r / min, and the lower sediment was washed with double distilled water to obtain a product with a particle size of 40nm.

Embodiment 3

[0029] Add 100 mL of chloroauric acid solution with a concentration of 100 μg / mL into a three-neck flask, add 10 mL of polyvinylpyrrolidone solution, and 10 mL of polyethylene glycol solution. Put the three-neck flask into a microwave reactor for reaction, set the microwave power to 650W, and the solution boils after 1.5 minutes. Quickly add 1 mL of sodium citrate solution with a concentration of 0.02 g / mL, continue the microwave reaction under stirring at 100 r / min, the microwave power is 325 W, and stop the reaction after 8 minutes. After the reaction was completed, 20 mL of cetyltrimethylammonium bromide solution was added to terminate the reaction. Finally, the reaction solution was centrifuged at a low speed of 1000r / min by a high-speed centrifuge, and the supernatant was then centrifuged at a high speed of 11000r / min, and the lower sediment was washed with twice distilled water to obtain a product with a particle size of 60nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com