Dry distillation charring method for bamboos

A bamboo and carbonization technology, applied in chemical instruments and methods, special forms of dry distillation, direct heating dry distillation, etc., can solve the problems of poor quality stability, high density of bamboo charcoal, high refining temperature, etc., and achieve strong electromagnetic wave shielding ability and high antistatic ability , the effect of high calcination temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

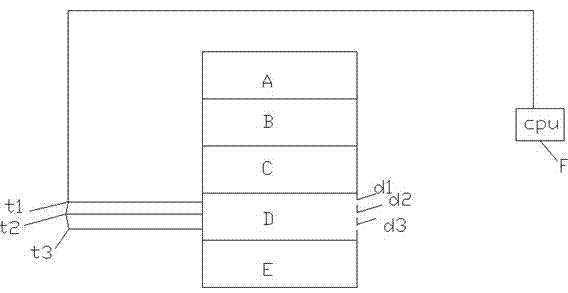

[0034] The pilot test was carried out in a vertical moving bed dry distillation carbonization furnace. Bamboo chips (about 36cm in length) with an average moisture content of 39% were used to measure the temperature of each temperature point. The drying zone A was 150°C, and the pre-carbonization zone B was 275°C. Carbonization zone C is 450°C, observed when the temperature rises figure 1 The zone D shown is the temperature of different positions in the combustion zone. When the temperature of a certain place in the combustion zone, such as d2, is too low, open the small hole in that place, introduce air and burn it nearby, so as to raise the temperature in this place and control the bamboo to move down. The temperature of the combustion zone experienced in the process was raised to 700°C at a rate of 5°C / min and kept for 40 minutes, and then raised from 700°C to 1100°C at a rate of 5°C / min and held for 2 hours. The bamboo charcoal cooling pipe and bamboo vinegar liquid condens...

Embodiment 2

[0038] The pilot test was carried out in a 16-tube conjoined moving bed carbonization furnace with Mengzong bamboo chips (about 40cm long) with an average moisture content of 30%, the temperature of each temperature measurement point, the drying zone A was 200 °C, and the pre-carbonization zone B is 270°C, and carbonization zone C is 500°C. When the temperature rises, part of the combustion gas introduced from the external combustion type and part of the non-condensable gas from the bamboo vinegar liquid condenser are combusted at the same time, so that the temperature of the combustion zone rises to 750 at a rate of 15°C / min. ℃ and keep it warm for 80 minutes, then raise the temperature from 750 ℃ to 1500 ℃ at a rate of 15 ℃ / min and keep it warm for 8 hours, spray water vapor into the 1500 ℃ area for 60 minutes, the bamboo charcoal cooling pipe and the bamboo vinegar liquid condenser adopt natural cooling, the discharge temperature is 30°C. Take out the bamboo charcoal afte...

Embodiment 3

[0042] The pilot test was carried out in a 16-tube conjoined moving bed carbonization furnace with Mengzong bamboo chips (about 40cm long) with an average moisture content of 35%, the temperature of each temperature measurement point, the drying zone A was 150°C, and the pre-carbonization zone B is 275°C, and carbonization zone C is 450°C. When the temperature rises, part of the combustion gas is introduced from the external combustion type, so that the temperature of the combustion zone is raised to 720°C at a rate of 12°C / min and kept for 60 minutes, and then at a rate of 12°C / min. The temperature was raised from 720°C to 1000°C and held for 6 hours. Carbon dioxide was sprayed into the 1000°C area for 30 minutes. The bamboo charcoal cooling pipe and the bamboo vinegar liquid condenser were naturally cooled, and the discharge temperature was 20°C. After 8 days of continuous operation (not including the furnace warming time), take out the bamboo charcoal, soak the taken out bam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| iodine adsorption value | aaaaa | aaaaa |

| iodine adsorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com