Heat-resistant solvent-free immersion paint and preparation method thereof

A solvent-free impregnating paint, high temperature resistance technology, applied in coatings, epoxy resin coatings, etc., can solve the problems of poor craftsmanship, undisclosed key raw materials, high viscosity of paint liquid, etc., and achieves broad application prospects, excellent resistance to Thermal, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

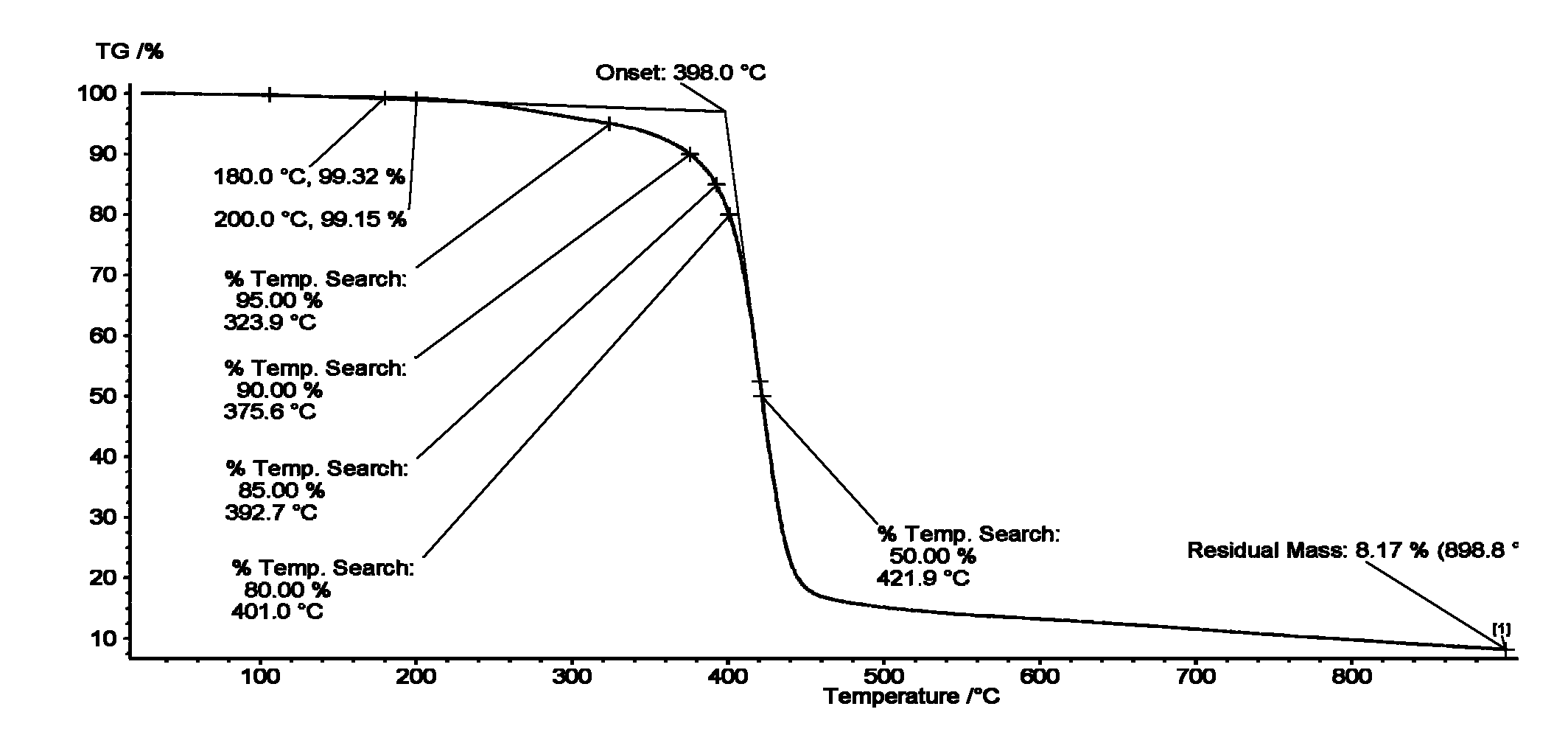

Image

Examples

Embodiment 1

[0037] Put 47.0 g (0.1 mole) of α, ω-diaminopropyl polymethylsiloxane organosilicon diamine into the reaction kettle, heat to 60°C, and add 157.0 g of E-51 bisphenol A type while stirring Epoxy resin (epoxy value 0.51), after stirring and reacting for 0.5 hours, heat up to 100°C, continue stirring and reacting for 0.5 hours to obtain a viscous organosilicon multifunctional epoxy resin, add 1000.0 grams of diglycidyl phthalate Ester and 326.0 grams of 3,4-epoxycyclohexylcarboxylic acid-3′,4′-epoxycyclohexyl methyl ester reactive diluent, 306.0 grams of N,N,N′,N′-tetraglycidyl-4 , 4'-diaminodiphenylmethane silicon-free polyfunctional epoxy resin was added to the reaction kettle, after reacting at 100°C for 0.5 hours, cooling, adding 54.0 grams of 3,3',4,4'-tetracarboxylic acid benzophenone Dianhydride and 150.0 grams of dicyandiamide curing agent powder were stirred evenly at room temperature to obtain a viscous liquid, which was a high-temperature-resistant solvent-free dipping...

Embodiment 2

[0045] Put 47.0 g (0.1 mole) of α, ω-diaminopropyl polymethylsiloxane organosilicon diamine into the reaction kettle, heat to 60°C, and add 227.0 g of E-44 bisphenol A type while stirring Epoxy resin (epoxy value 0.44), after stirring and reacting for 0.5 hours, be warming up to 100 ℃, continue stirring and reacting for 0.5 hours, obtain viscous organosilicon multifunctional epoxy resin, add 322.6 grams of diglycidyl isophthalate Ether, 200.0 grams diglycidyl hydrogenated bisphenol A and 300.0 grams 3',4'-epoxycyclohexylmethyl 3,4-epoxycyclohexylcarboxylate reactive diluent, 339.8 grams N,N,O - Triglycidyl-4-aminophenol and 300.0 g of N,N,N',N'-tetraglycidyl-3,3'-dimethyl-4,4'-diaminodiphenylmethane silicone-free poly Put the functional epoxy resin into the reaction kettle, react at 100°C for 0.5 hours, cool, add 30.0 grams of 4,4'-diaminodiphenyl sulfone and 61.4 grams of dicyandiamide curing agent powder, and stir evenly at room temperature to obtain a viscous The thick liq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| gel time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com