Method for modifying manganese ore and application thereof in removal of arsenic from groundwater permeable reactive wall

A manganese ore, the purpose of the technology, the application in the groundwater osmotic reaction wall to remove arsenic, the field of manganese ore modification, can solve the problems of expensive materials and complicated preparation process, and achieve simple preparation process, low raw material cost and low energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

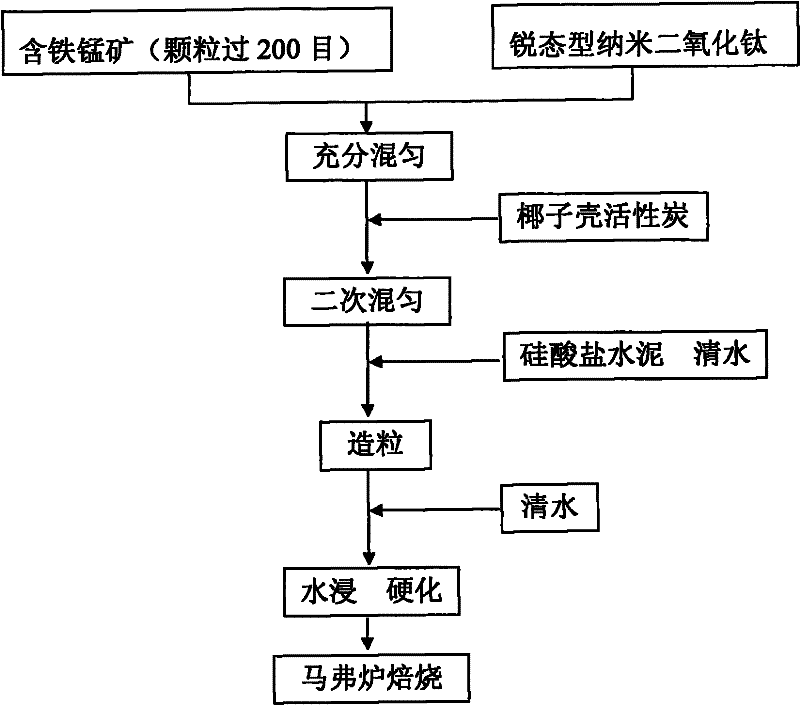

Method used

Image

Examples

Embodiment 1

[0072] A manganese ore modification method, the components by weight are as follows:

[0073] Based on the dry basis of the finished product as 200kg:

[0074] Iron-containing manganese ore (manganese content 40%-50%, iron content 15-25%, particles over 200 mesh) 135kg;

[0075] Sharp nano titanium dioxide 1kg;

[0076] Coconut shell activated carbon 14kg;

[0077]Ordinary Portland cement (label 325) 50kg;

[0078] Add water 100kg;

[0079] The firing temperature is 200°C;

[0080] Prepare as follows:

[0081] 1) Fully mix manganese ore and sharp nano-titanium dioxide according to the formula for 15 minutes to obtain material 1;

[0082] 2) Add activated carbon to material 1 and continue to mix uniformly to obtain material 2;

[0083] 3) The obtained material 2 is sprayed with clear water and ordinary Portland cement under stirring, and fully mixed to obtain material 3;

[0084] 4) making the obtained material 3 into 1-3 cm spherical particles with an extrusion granula...

Embodiment 2

[0089] A manganese ore modification method, the components by weight are as follows:

[0090] Based on the dry basis of the finished product as 200kg:

[0091] Iron-containing manganese ore (manganese content 40%-50%, iron content 15-25%, particles over 200 mesh) 147kg;

[0092] Sharp nano titanium dioxide 3kg;

[0093] Coconut shell activated carbon 10kg;

[0094] Ordinary Portland cement (label 325) 40kg;

[0095] Add water 150kg;

[0096] The firing temperature is 180°C.

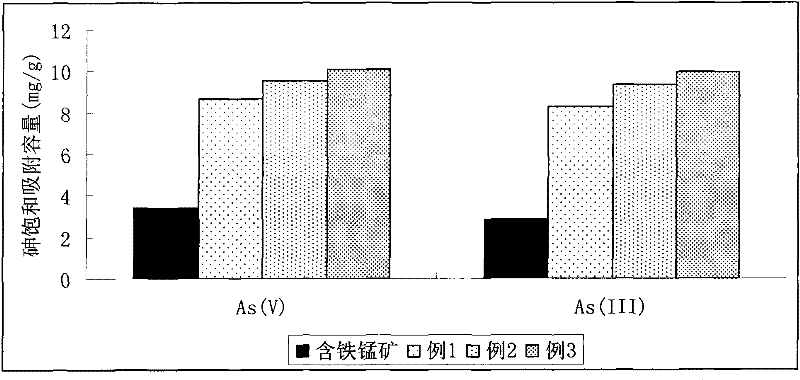

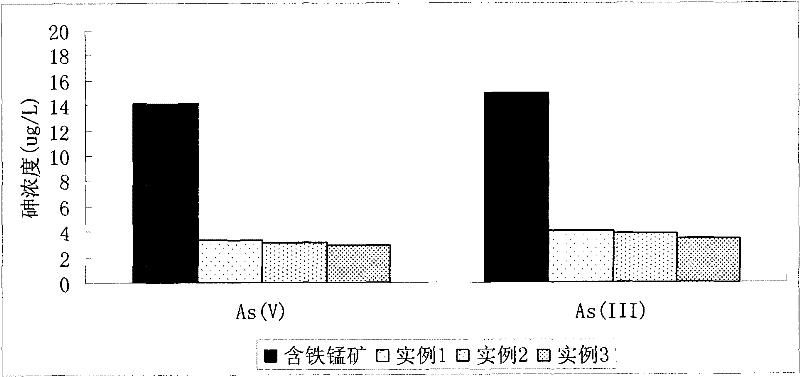

[0097] The arsenic-removing material prepared in this example was adsorbed in an indoor simulated osmotic reaction wall with simulated underground wastewater containing 200 μg / L As(V) / As(III) under laboratory conditions. The saturated adsorption capacity for arsenic is As(III): 9.356mg / g and As(V): 9.548mg / g. The adsorption of As(III) and As(V) conforms to the second-order kinetic equation, and the correlation R 2 = 0.9992. The validity period can be up to 9.5 years.

Embodiment 3

[0099] A manganese ore modification method, the components by weight are as follows:

[0100] Based on the dry basis of the finished product as 200kg:

[0101] Iron-containing manganese ore (manganese content 40%-50%, iron content 15-25%, particles over 200 mesh) 155kg;

[0102] Sharp nano titanium dioxide 5kg;

[0103] Coconut shell activated carbon 5kg;

[0104] Ordinary Portland cement (label 325) 35kg;

[0105] Add water 200kg;

[0106] The firing temperature is 150°C.

[0107] The arsenic-removing material prepared in this example was adsorbed in an indoor simulated osmotic reaction wall with simulated underground wastewater containing 200 μg / L As(V) / As(III) under laboratory conditions. The saturated adsorption capacity for arsenic is As(III): 9.931 mg / g and As(V): 10.101 mg / g. The adsorption of As(III) and As(V) conforms to the second-order kinetic equation, and the correlation R 2 = 0.9922. Validity can be up to 10 years.

[0108] According to the technical sch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com