Nano multifunctional outer wall heat preservation coating

An external wall insulation and multi-functional technology, applied in the direction of coating, etc., can solve the problems of low strength in the later stage of the product, low fire resistance and weather resistance, flammability of thermal insulation coatings, etc., to achieve stable molding, strong adhesion, and improved thermal insulation The effect of the characteristic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

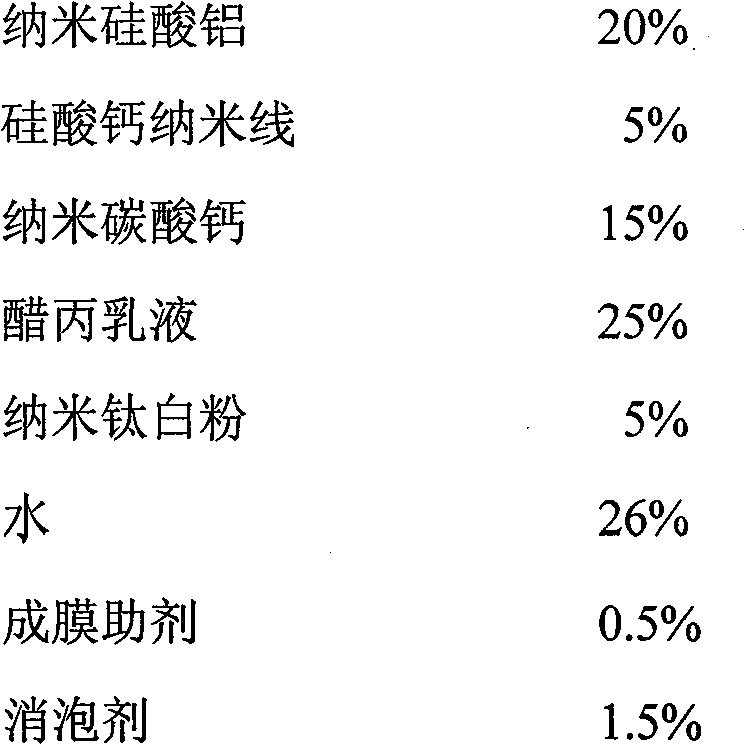

[0018] Embodiment 1: the mass percent composition of this kind of nanometer multifunctional exterior wall thermal insulation coating is as follows:

[0019]

[0020] Wetting and dispersing agent 0.5%

[0021] Antifreeze 1%

[0022] Leveling agent 0.5%

[0023] The preparation method of the nanometer multifunctional exterior wall insulation coating provided by the present embodiment is as follows:

[0024] Stir water, nano-aluminum silicate, calcium silicate nanowires, nano-calcium carbonate, wetting and dispersing agent, and half of the defoamer at high speed for 1 hour under low-speed stirring, and then add other inorganic nano-powders under stirring. Stir on a disperser at high speed for 1 hour, then slowly add the emulsion dropwise at a low stirring speed, then add the remaining defoamer, film-forming aid, antifreeze, and leveling agent and stir at low speed for 3 hours, and finally pack into a can to obtain the finished coating.

Embodiment 2

[0025] Embodiment 2: the mass percent composition of this kind of nanometer multifunctional exterior wall thermal insulation coating is as follows:

[0026] Nano aluminum silicate 10%

[0027] Calcium silicate nanowires 10%

[0028] Nano Calcium Carbonate 20%

[0029] Styrene Acrylic Emulsion 25%

[0030] Nano titanium dioxide 6%

[0031] water 25%

[0032] Coalescent 0.5%

[0033] Defoamer 1%

[0034] Wetting and dispersing agent 1%

[0035] Antifreeze 0.5%

[0036] Leveling agent 1%

[0037] The preparation method of the nanometer multifunctional exterior wall insulation coating provided by the present embodiment is as follows:

[0038] Stir water, nano-aluminum silicate, calcium silicate nanowires, nano-calcium carbonate, wetting and dispersing agent, and half of the defoamer at high speed for 1 hour under low-speed stirring, and then add other inorganic nano-powders under stirring. Stir on a disperser at high speed for 2 hours, then slowly add the emulsion dropwi...

Embodiment 3

[0039] Embodiment 3: the mass percent composition of this kind of nanometer multifunctional exterior wall thermal insulation coating is as follows:

[0040] Nano aluminum silicate 15%

[0041] Calcium silicate nanowires 5%

[0042] Nano Calcium Carbonate 15%

[0043] Vinegar Acrylic Emulsion 25%

[0044] Nano Titanium Dioxide 8%

[0045] water 28%

[0046] Coalescent 0.5%

[0047] Defoamer 1%

[0048] Wetting and dispersing agent 1%

[0049] Antifreeze 1%

[0050] Leveling agent 0.5%

[0051] The preparation method of the nanometer multifunctional exterior wall insulation coating provided by the present embodiment is as follows:

[0052] Stir water, nano-aluminum silicate, calcium silicate nanowires, nano-calcium carbonate, wetting and dispersing agent, and half of the defoamer at high speed for 2 hours under low-speed stirring, and then add other inorganic nano-powders under stirring. Stir on a disperser at high speed for 3 hours, then slowly add the emulsion dropwi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| minimum film forming temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com