Phosphorus-containing and nitrogen-containing expansion type flame-retardant polymer and preparation method thereof

A flame retardant polymer, nitrogen expansion technology, applied in nitrogen expansion flame retardant polymer and its preparation, phosphorus-containing field, can solve the problem of reducing the flame retardant performance and service life of materials, unable to meet plastic processing requirements, low decomposition temperature, etc. problems, to achieve broad industrial application prospects, good fire protection, and good compatibility.

Active Publication Date: 2010-12-15

UNIV OF SCI & TECH OF CHINA

View PDF12 Cites 26 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, most intumescent flame retardants have the following disadvantages: first, their decomposition temperature is low, which cannot meet the processing requirements of some plastics; Permeation and precipitation reduce the flame retardancy and service life of the material

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

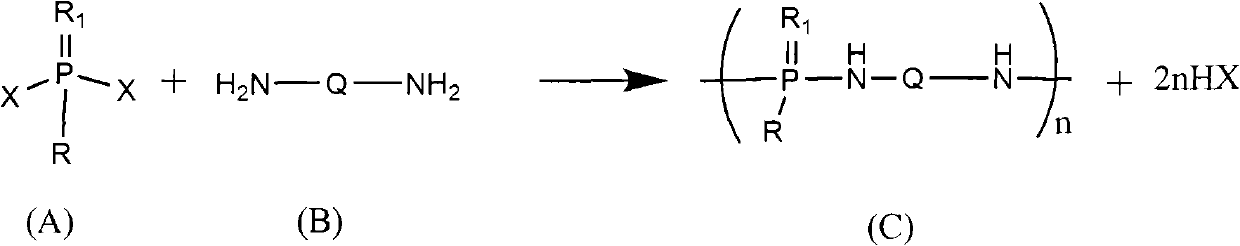

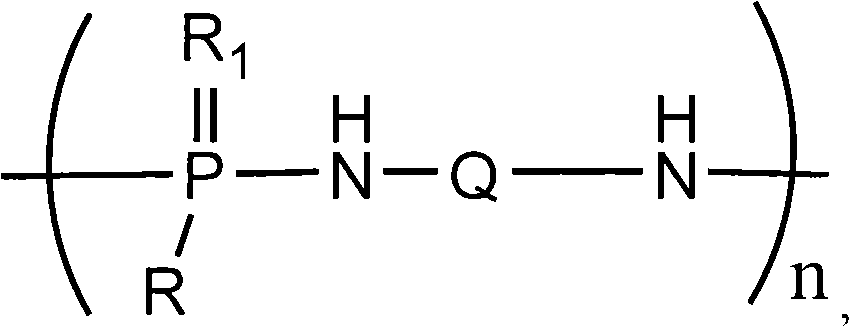

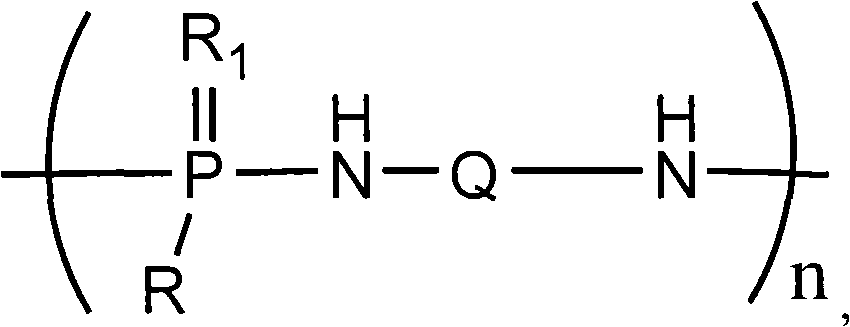

Login to View More Abstract

The invention discloses a phosphorus-containing and nitrogen-containing expansion type flame-retardant polymer and a preparation method thereof. The preparation method is characterized in that: the phosphorus-containing and nitrogen-containing expansion type flame-retardant polymer is prepared by solution polycondensation reaction or melt polycondensation reaction of diphosphorus acylchloride or diphosphorus acylbromide and a diamine functional group-containing compound. The expansion type flame-retardant polymer comprises phosphorus-containing and nitrogen-containing phosphamide with a structure unit formula shown in the specifications, wherein n is an integer of from 1 to 200; R1 is oxygen or sulphur; and R is alkoxy, alkylthio, aryloxy or arylthio. The product of the invention has high compatibility with a high molecular material matrix, difficult transfer and excellent durability. The preparation method has the advantages of simpleness, easy control, high yield, wide sources of the required raw materials and easy industrialized production. A high polymer with a flame-retardant function can be directly prepared, or the high polymer serving as a flame-retardant additive can be added into various polyesters, polyamide, polyolefin, epoxy resin, polystyrene, high impact polystyrene or acrylonitrile butadiene styrene (ABS) polymer.

Description

technical field The invention belongs to the technical field of halogen-free flame-retardant polymers, and in particular relates to phosphorus- and nitrogen-containing intumescent flame-retardant polymers and a preparation method thereof. Background technique Polymer materials have many advantages such as light weight, chemical corrosion resistance, easy processing and molding, wide operating temperature range, and high cost performance. They have been widely used in electronics, electrical appliances, construction and other fields and in daily life. However, because most polymer materials are composed of C, H, O and other elements, they are easy to burn and cause fires, which bring huge threats and losses to people's lives and property. At present, the industry mainly adopts the addition of halogen-containing flame retardants in the matrix of polymer materials to solve the problem of flammability of polymer materials. For example, some bromine-containing flame retardants ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08G79/02

Inventor 胡源台启龙宋磊

Owner UNIV OF SCI & TECH OF CHINA

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com