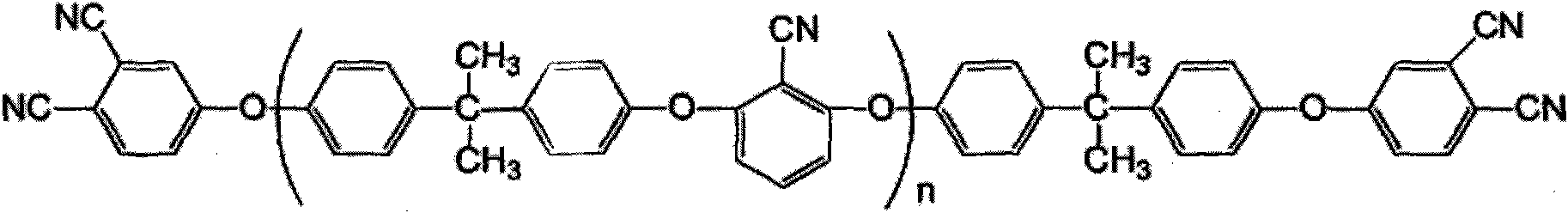

Bisphenol A type bis-phthalonitrile resin with aryl ether nitrile segments, cured product and preparation method thereof

A technology of phthalonitrile resin and bisphthalonitrile, which is applied to the preparation of carboxylic acid nitrile, chemical instruments and methods, and the preparation of organic compounds, can solve the problem of low melting point, post-curing temperature preparation method, The post-curing temperature is high and the problems have not been well solved, so as to achieve the effect of excellent curing molding performance, lower curing processing temperature, and wide processing temperature window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Preparation of bisphenol A type bis-phthalonitrile resin containing aryl ether nitrile chain segment (n=2) and cured product of the present invention

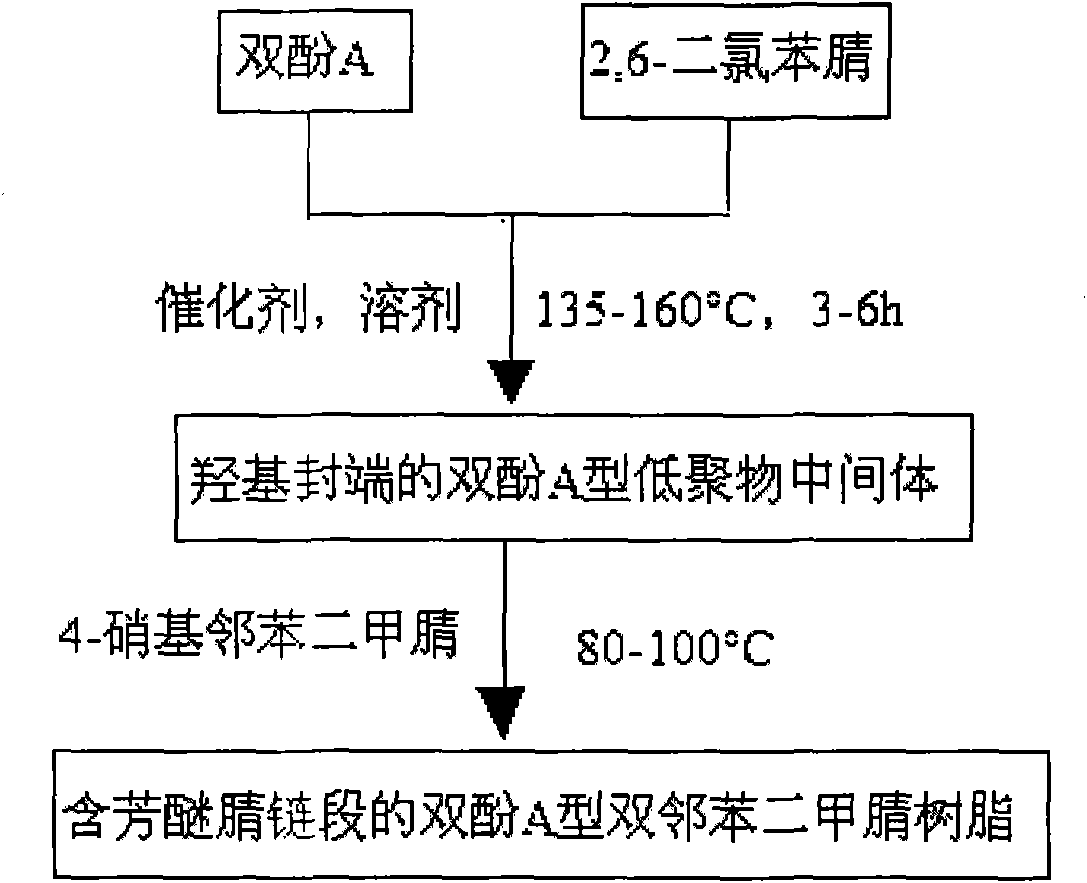

[0061] (1) Synthesis of bisphenol A type bis-phthalonitrile resin containing aryl ether nitrile segment (n=2):

[0062] Step 1: Add bisphenol A, 2,6-dichlorobenzonitrile, anhydrous potassium carbonate, N,N-dimethylformamide / toluene mixed solvent into a reaction vessel with water separation device, heat to 130 ℃ reflux reaction for 6 hours; then release the by-product water and toluene generated by the reaction in the water separator, continue to raise the temperature to distill out the residual toluene in the reaction system, and then cool to room temperature.

[0063] Step 2: Add 4-nitrobisphthalonitrile to the reaction vessel with the water separation device described in step 1, and react at 90° C. for 6 hours.

[0064] Step 3: Pour the reaction mixture of step 2 into 0.1mol / L HCl solution to precipitate, filter, wash...

Embodiment 2

[0074] The invention relates to the preparation of the bisphenol A type bisphthalonitrile resin containing aryl ether nitrile chain segment (n=4) and its cured product.

[0075] (1) Synthesis of bisphenol A type bis-phthalonitrile resin containing aryl ether nitrile segment (n=4):

[0076] Step 1: Add bisphenol A, 2,6-dichlorobenzonitrile, anhydrous potassium carbonate, N,N-dimethylformamide / toluene mixed solvent into a reaction vessel with a water separator, heat to 150 Reflux reaction at ℃ for 3.5 hours; then release the by-product water and toluene generated by the reaction in the water separator, continue to raise the temperature to distill out the residual toluene in the reaction system, and then cool to room temperature.

[0077] Step 2: Add 4-nitrobisphthalonitrile to the reaction vessel with the water separation device described in step 1, and react at 85° C. for 9.5 hours.

[0078] Step 3: Pour the reaction mixture of step 2 into 0.1mol / L HCl solution to precipitate,...

Embodiment 3

[0088] The invention relates to the preparation of the bisphenol A type bisphthalonitrile resin containing aryl ether nitrile chain segment (n=6) and its cured product.

[0089](1) Synthesis of bisphenol A type bis-phthalonitrile resin containing aryl ether nitrile segment (n=6):

[0090] Step 1: Add bisphenol A, 2,6-dichlorobenzonitrile, anhydrous potassium carbonate, and N-methylpyrrolidone / toluene mixed solvent into a reaction vessel with a water separation device, and heat to 160°C for reflux reaction 3 hour; Then emit the by-product water and toluene generated by the reaction in the water trap, continue to heat up and distill out the residual toluene in the reaction system and then cool to room temperature.

[0091] Step 2: Put 4-nitrobisphthalonitrile into the reaction vessel with the water separation device described in step 1, and react at 90° C. for 9 hours.

[0092] Step 3: Pour the reaction mixture of step 2 into 0.1mol / L HCl solution to precipitate, filter, wash w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com