Glass composite for back surface field aluminum paste of solar battery and preparation method thereof

A glass composition and a technology for solar cells, applied in the field of glass composition for solar cell back field aluminum paste and its preparation, can solve problems such as environmental and human harm, and achieve elimination of lead pollution, low warpage, and cell conversion efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

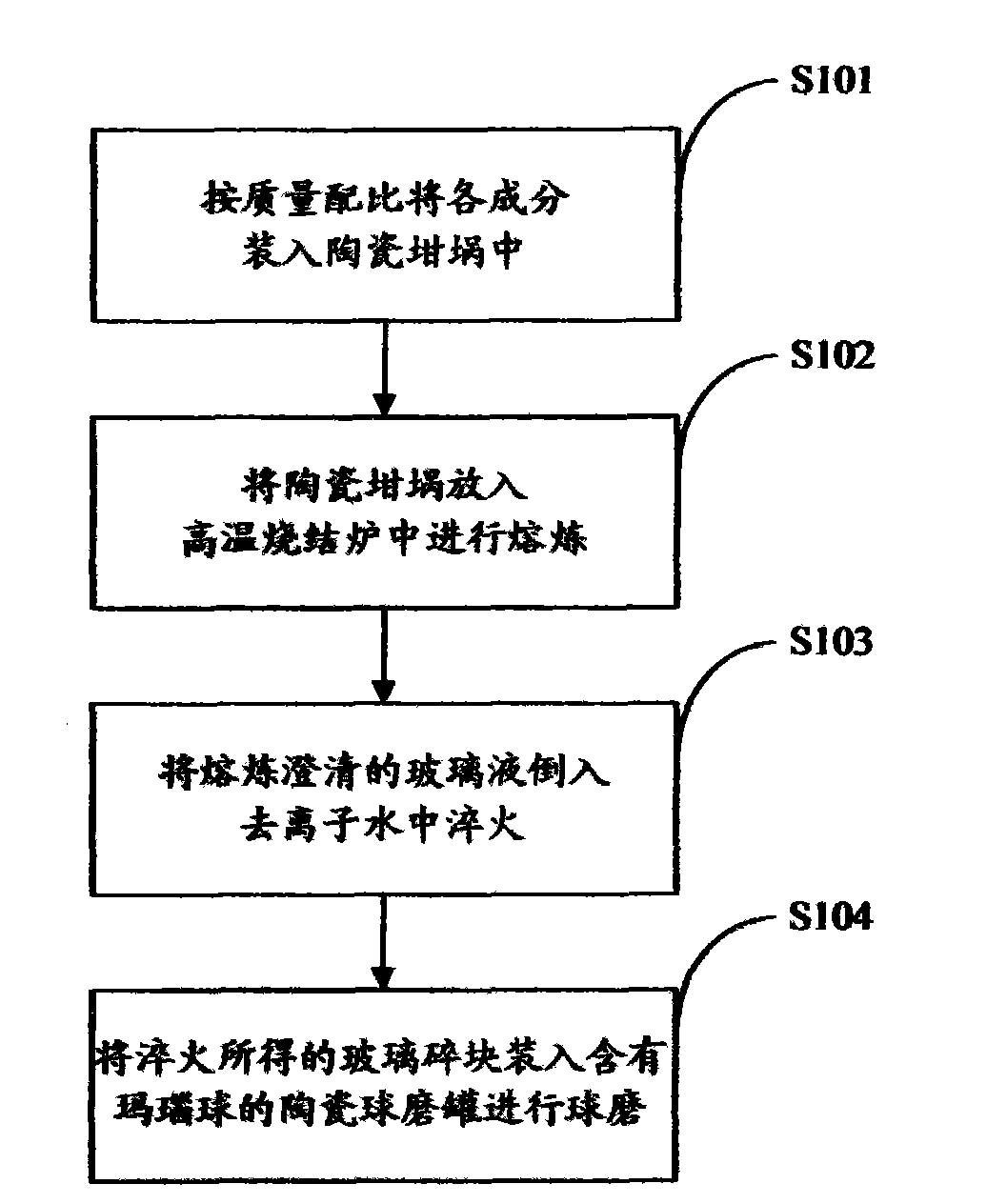

[0031] The content of the glass composition (glass bonding phase) in the back field aluminum paste of the present embodiment is 1-3%, preferably 1-2.5%, and its preparation method is as follows figure 1 shown, including the following steps:

[0032] S101, filling each component into a ceramic crucible according to the mass ratio;

[0033] Wherein, the mass ratio of each composition is as follows: Bi 2 o 3 , 65-75%; SiO 2 , 5-10%; B 2 o 3 , 6-8%; Al 2 o 3 , 0-2%; ZnO, 8-10%; CaO 0-2%; modification additive, 0-2%; as described in the above examples, the modification additive here includes TiO 2 , ZrO 2 , V 2 o 5 , CaF and other components.

[0034] S102, putting the ceramic crucible into a high-temperature sintering furnace for melting;

[0035] The specific smelting conditions can be smelting at 1200-1300°C for 1-2 hours.

[0036] S103, pouring the smelted and clarified molten glass into deionized water for quenching;

[0037] S104, putting the quenched glass frag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com