Method for modifying anode active material of lithium ion battery

A positive active material, lithium-ion battery technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve problems such as instability, uneven distribution of coating film thickness, uneven flow field, etc., to avoid being Oxidation, avoid side reactions, improve overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Add 485g LiCoO to 1L of deionized water and ethanol mixed solution 2and 7.6g ZrOCl, stir well; add ammonia water dropwise to adjust the pH value of the mixture to 7, and stir and mix for 2 hours; use a centrifugal device with an aperture of 800 mesh and an inner diameter of 1200mm to fully centrifuge for 3 hours; wash and centrifuge repeatedly with deionized water Mixture until the pH value of the flushing solution reaches 5; then dry at a constant temperature of 200°C for 2 hours under the protection of argon; and bake at 800°C for 5 hours, and slowly cool to room temperature to obtain a coating with a coating amount of about 1%. Coated positive electrode active material.

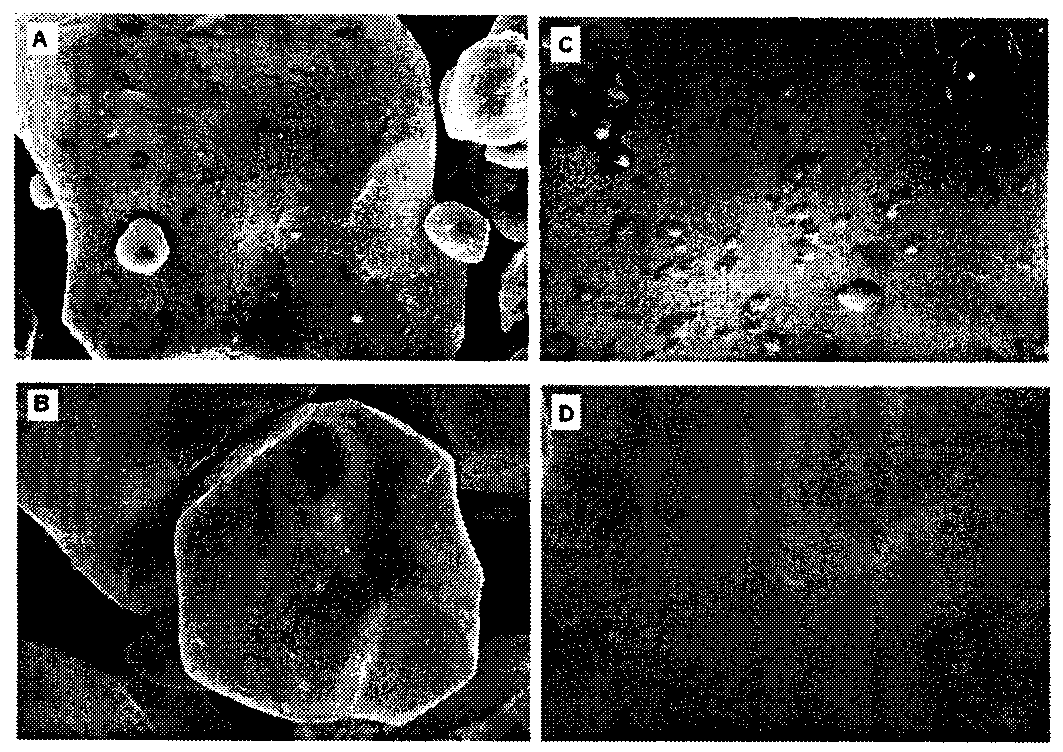

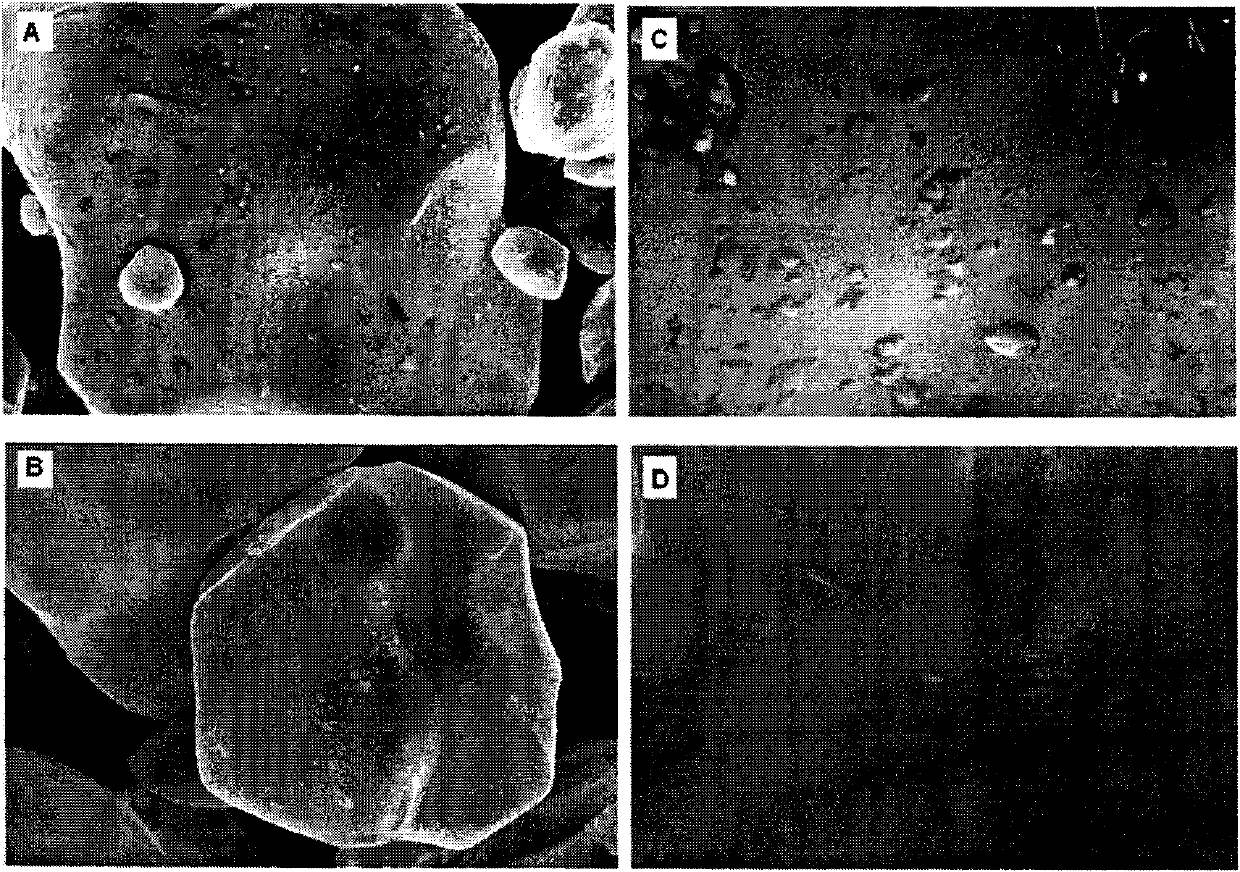

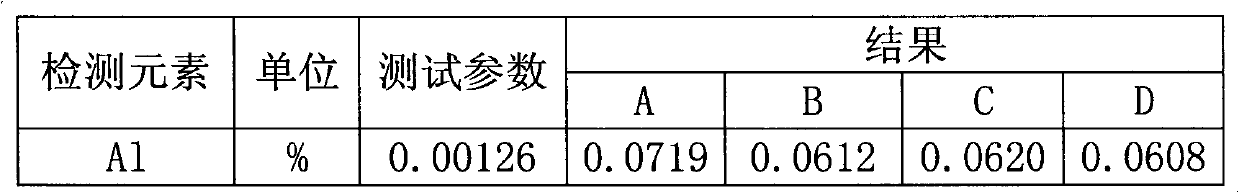

[0023] like figure 1 As shown, the sample prepared by the above method is imaged under the SEM microscope as figure 1 B, D in ; the material obtained by stirring only during the solid-liquid separation of the mixture without centrifugation is imaged under SEM as in A, C in 1. It is confirmed by t...

Embodiment 2

[0026] Add 520g LiNi in 2L deionized water 1 / 3 co 1 / 3 mn 1 / 3 o 2 and 10.3gAl(NO 3 ) 3 Stir evenly; add 0.5M ammonia water dropwise to adjust the pH value of the mixture to 6.5, and use a centrifugal device with a pore size of 600 mesh and an inner diameter of 700 mm to fully centrifuge for 1.5 hours; repeatedly rinse the centrifuged mixture with deionized water until the pH of the washing solution value is 6, and then dried at a constant temperature of 180° C. for 3 hours under the protection of nitrogen; and baked at 1000° C. for 5 hours, and slowly cooled to room temperature to obtain a coated positive electrode active material with a coating amount of about 0.25%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com