Waterborne polyurethane adhesive for RFID antenna substrate

A technology of water-based polyurethane and adhesive, applied in the direction of polyurea/polyurethane adhesive, adhesive, adhesive type, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

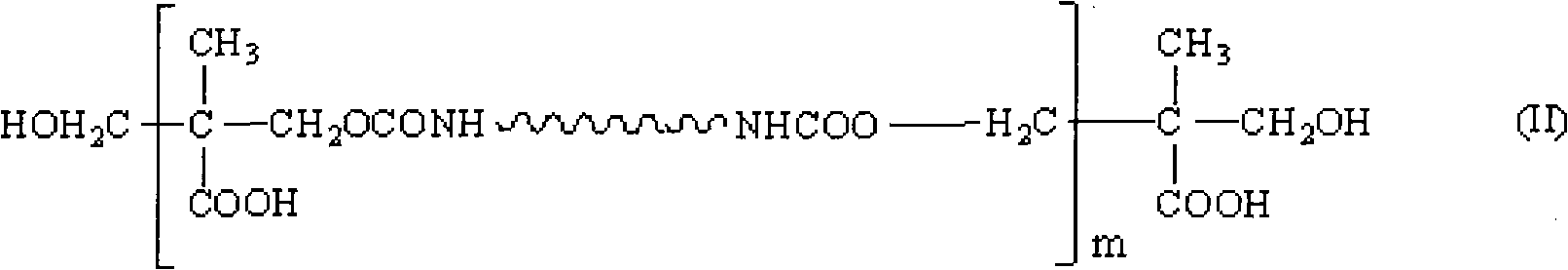

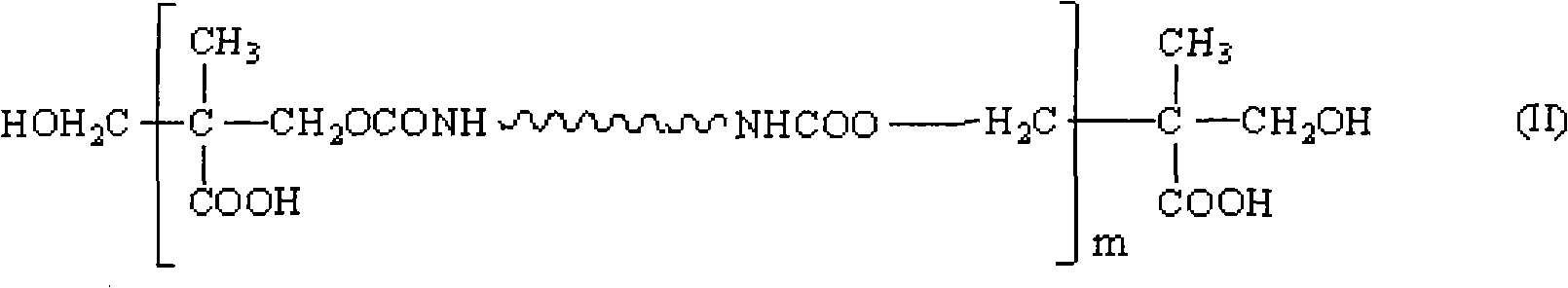

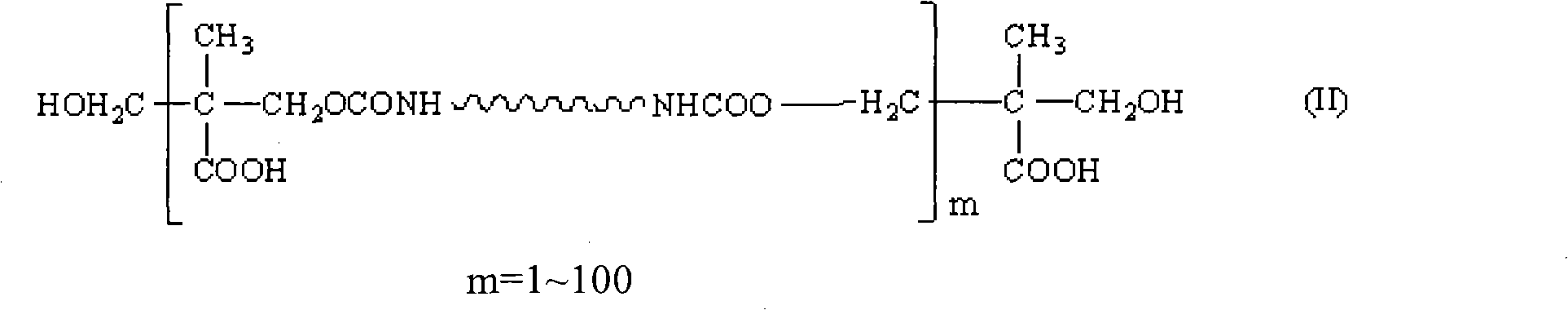

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Add 110g of polyester diol into a 500ml three-necked bottle equipped with a stirrer, an N2 gas guide tube and a thermometer, heat and melt at 120°C and 5mmHg, and vacuum dehydrate for 1 hour. Cool to about 60°C, add 43.2g of toluene diisocyanate (TDI), 0.35g of dibutyltin dilaurate (DBTDL) catalyst, 40g of methyl ethyl ketone, and keep warm at about 76°C for 1 hour to obtain a translucent liquid. Add 8.1g of 2,2'-dihydroxypropionic acid (DMPA), react at 70°C for 1 hour, react at 80°C for 1 hour, cool to 70°C, add 10g of 1,4-butanediol (BDO), and react for 2 hours , a yellowish translucent liquid was obtained. Cool to below 40°C, add triethylamine, adjust the pH to above 7, and keep the temperature for 0.5 hours to prepare a prepolymer, pour the obtained prepolymer into water containing 0.7wt% sodium dodecylbenzenesulfonate, Stir vigorously for 30 minutes, heat and vacuum distill butanone off to obtain a translucent bluish water-based polyurethane emulsion with a solid ...

Embodiment 2

[0041] The synthesis steps of the water-based polyurethane adhesive are the same as those in Example 1. The polyester polyol is replaced by polyether polyol, the methyl ethyl ketone is replaced by acetone, the reaction temperature for preparing the prepolymer is 85°C, the chain extension reaction temperature is 75°C, and the reaction is carried out for 4 hours. Aqueous polyurethane emulsion was prepared. Then mix 4 parts of dispersible polyisocyanate with 10 parts of water-based polyurethane emulsion, coat it on the polyester film, dry the solvent at 85°C, press it with aluminum foil or copper foil at 120°C, and cure at 110°C for 0.5 hours to obtain RFID antenna base material, the performance is shown in Table 1.

Embodiment 3

[0043] The synthesis steps of the water-based polyurethane adhesive are the same as in Example 1, replacing toluene diisocyanate with isophorone diisocyanate, sodium dodecylbenzenesulfonate with stearic acid, the prepolymer reaction temperature is 80°C, and the chain extension reaction temperature at 70°C for 3 hours to prepare a water-based polyurethane emulsion. Then mix 4 parts of blocked isocyanate with 8 parts of water-based polyurethane emulsion, coat it on the paper base, dry the solvent at 80°C, press it with aluminum foil or copper foil at 120°C, and cure it at 110°C for 1.5 hours to get the RFID antenna The properties of the base material are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com