Method for preparing polycarboxylic acid water reducer macromer

A technology of water reducing agent and macromonomer, which is applied in the field of preparation of polycarboxylate water reducing agent intermediates, can solve the problems of complex reaction equipment and unstable reaction system, and achieve simple reaction equipment, stable reaction, and esterification rate. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

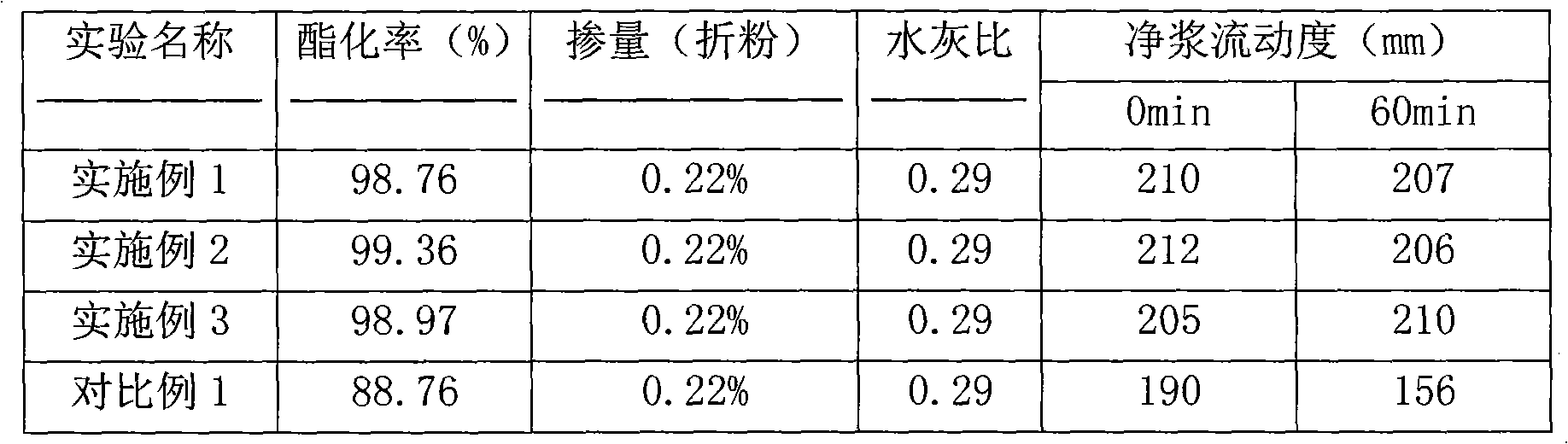

Embodiment 1

[0022] In the reactor with good airtightness, under the condition of constant stirring, add 1000Kg of molecular weight 1000 polyethylene glycol monomethyl ether, 1.22Kg of hydroquinone, 1.22Kg of phenothiazine, and 350Kg of methacrylic acid. 15-30min, then slowly add 20Kg of concentrated sulfuric acid, and start to heat up. When the temperature reaches 100℃, close all the vent valves of the reactor and blow in nitrogen to keep the pressure in the reactor at 0.1Mpa. Continue to heat up to 125-130°C and keep it at this temperature for 6 hours. After the reaction is completed, polyethylene glycol monomethyl ether methacrylate, which is a macromonomer of polycarboxylic acid water reducing agent, is obtained. After the reaction, the measured esterification rate was 98.76%.

Embodiment 2

[0024] In a relatively tightly sealed reaction vessel, under the condition of constant stirring, add 1000Kg of molecular weight of 1000 polyethylene glycol monomethyl ether, 1.75Kg of hydroquinone, 290Kg of acrylic acid, and stir for 15-30min, and then slowly add concentrated Sulfuric acid 9.7Kg, p-toluenesulfonic acid 9.7Kg, and start to heat up. When the temperature reaches 100°C, close all vent valves of the reactor and blow in nitrogen to keep the pressure in the reactor at 0.2Mpa. Continue to heat up to 125-130°C and keep it at this temperature for 6 hours. After the reaction is completed, polyethylene glycol monomethyl ether acrylate, which is a macromonomer of polycarboxylic acid water reducing agent, is obtained. After the reaction, the measured esterification rate was 99.36%.

Embodiment 3

[0026] In a relatively tightly sealed reactor, under the condition of constant stirring, add 1000Kg of molecular weight 1000 polyethylene glycol monomethyl ether, 1.85Kg of p-benzoquinone, and 330Kg of methacrylic acid, stir for 15-30min, and then slowly add Concentrated sulfuric acid was 21.5Kg and started to heat up. When the temperature reached 100°C, all vent valves of the reactor were closed, and carbon dioxide gas was introduced to keep the pressure in the reactor at 0.1Mpa. Continue to heat up to 125-130°C and keep it at this temperature for 6 hours. After the reaction is completed, polyethylene glycol monomethyl ether methacrylate, which is a macromonomer of polycarboxylic acid water reducing agent, is obtained. After the reaction, the measured esterification rate was 98.97%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com