Modified xanthan gum nano-micelle preparation method

A technology of nano-micelle and nano-micelle solution, which is applied in the directions of non-active ingredients medical preparations, medical preparations containing active ingredients, pharmaceutical formulas, etc. It can improve the drug release time, enhance the antioxidant performance, and be less prone to oxidative degradation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

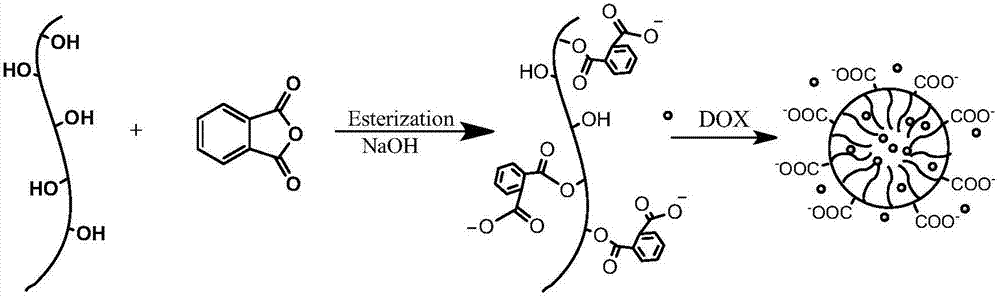

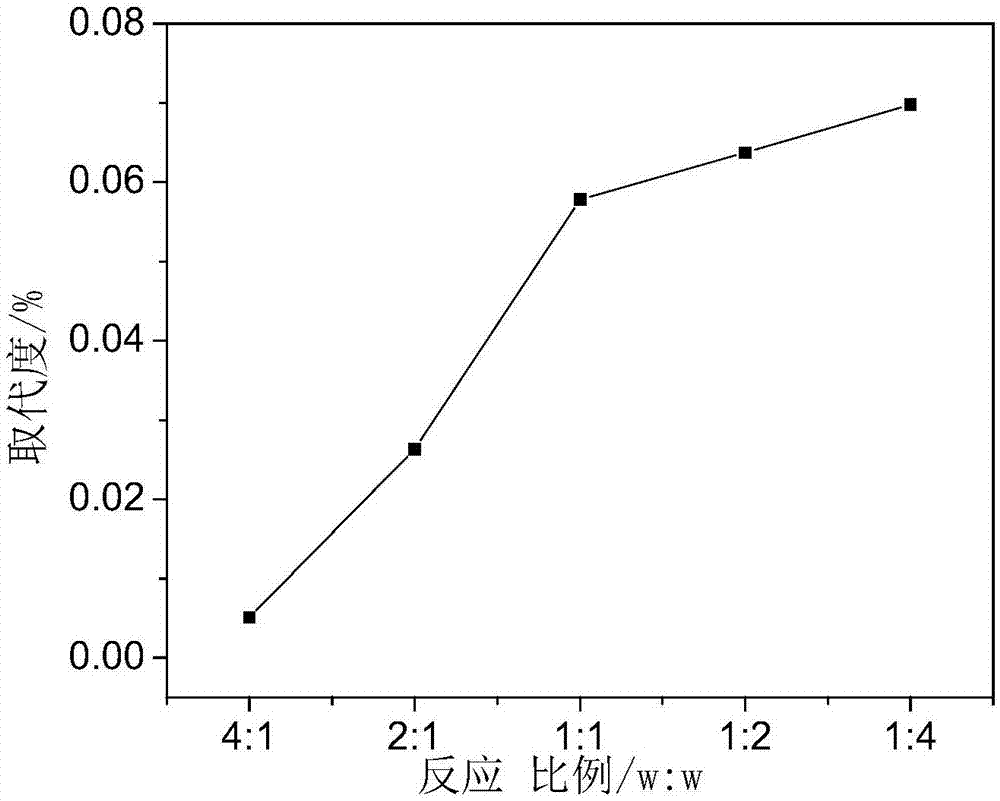

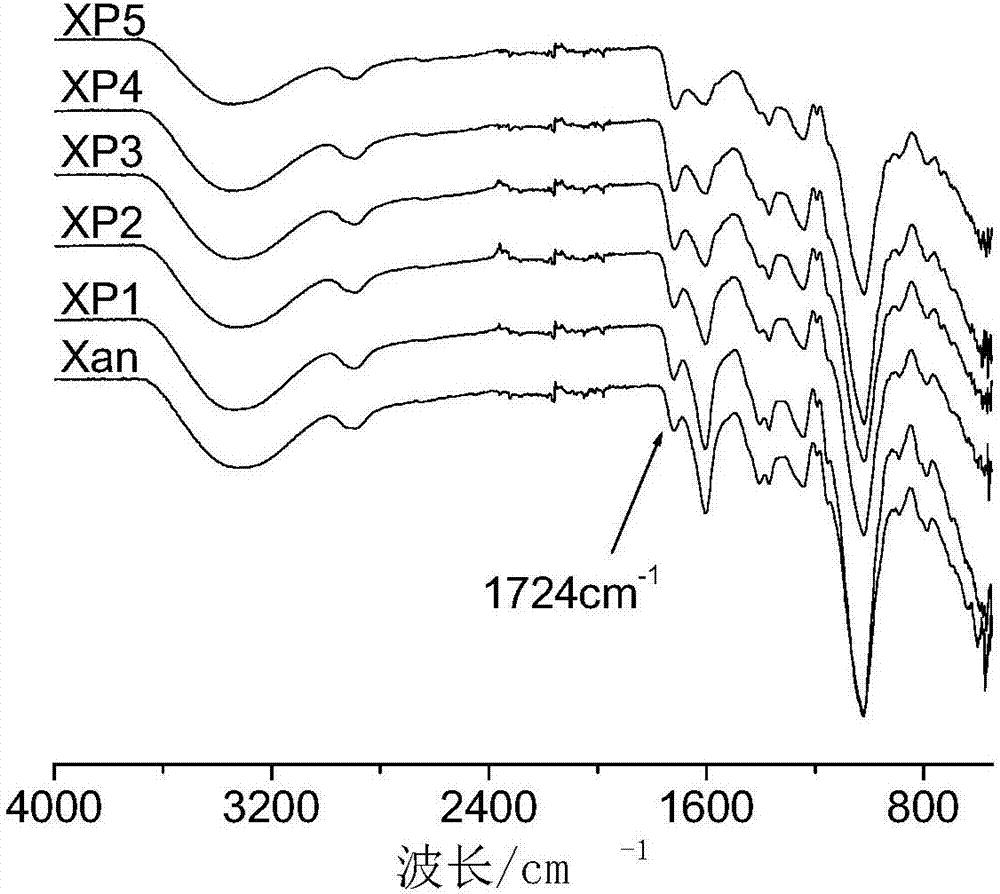

[0032] 1-1) Phthalic anhydride modified xanthan gum to synthesize amphiphilic modified xanthan gum polymer:

[0033]Dissolve 2g of xanthan gum in 200mL of deionized water, stir it evenly, add 0.06g of 4-dimethylaminopyridine, slowly add 20mL of acetone solution with 0.5g of phthalic anhydride to the above xanthan gum solution , stir evenly, heat up to 60°C for 12 hours, then cool to room temperature, precipitate with 3 times the volume of ethanol, filter, wash the precipitate with ethanol three times, and dry in vacuum at 60°C to constant weight to obtain phthalic anhydride modified xanthogen Glue the crude product; dissolve the crude product with deionized water, configure it into a 0.5w% solution, and move it to a dialysis bag with a molecular weight cut-off of 14000. The deionized water is the external fluid for dialysis. Change the external fluid for dialysis every 5 hours. After less than 72 hours, unreacted small molecules and catalysts were removed, and the dialysis sam...

Embodiment 2

[0039] As shown in Example 1-1), the xanthan gum aqueous solution is prepared, the same amount of catalyst is added, and 20 mL of acetone solution with 1.0 g of phthalic anhydride is slowly added dropwise to the above-mentioned xanthan gum solution, stirred evenly, and heated After reacting at 60°C for 12 hours, cool to room temperature, post-treatment as in Example 1-1), prepare modified xanthan gum nanomicelles as in Example 1-2), and prepare drug-loaded modified xanthan gum nanomicelles as in the implementation Example 1-3), the obtained modified xanthan gum nano-micelle is denoted as XP2.

Embodiment 3

[0041] As shown in Example 1-1), prepare an aqueous solution of xanthan gum, add the same amount of catalyst, slowly add 20 mL of acetone solution that is dissolved with 2.0 g of phthalic anhydride into the above-mentioned xanthan gum solution, stir evenly, and heat up After reacting at 60°C for 12 hours, cool to room temperature, post-treatment as in Example 1-1), prepare modified xanthan gum nanomicelles as in Example 1-2), and prepare drug-loaded modified xanthan gum nanomicelles as in the implementation Example 1-3), the obtained modified xanthan gum nano-micelle is denoted as XP3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com