Method for preparing lead-titanate-lead-magnesium niobate films by pulsed laser deposition assisted by oxygen plasmas

An oxygen plasma, lead magnesium niobate technology, applied in crystal growth, chemical instruments and methods, single crystal growth and other directions, can solve the problems of decreased grain density, reduced film-forming ion energy, loose grain boundary structure, etc. To achieve the effect of dense structure, optimized growth conditions and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

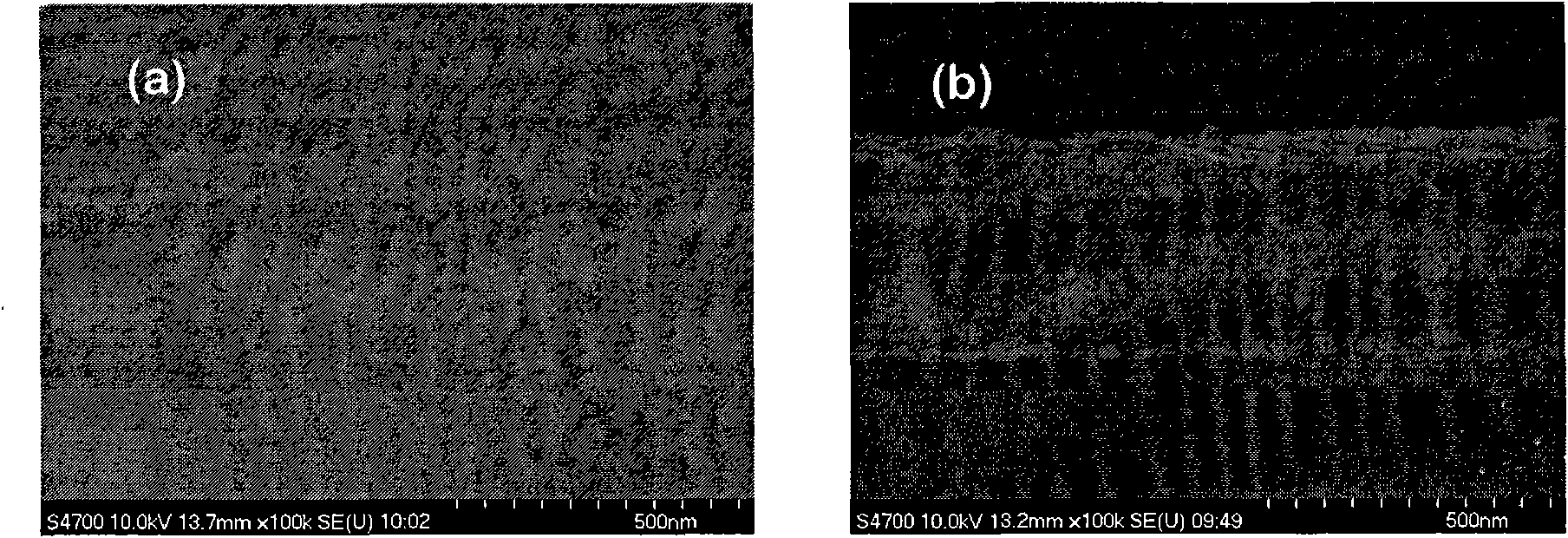

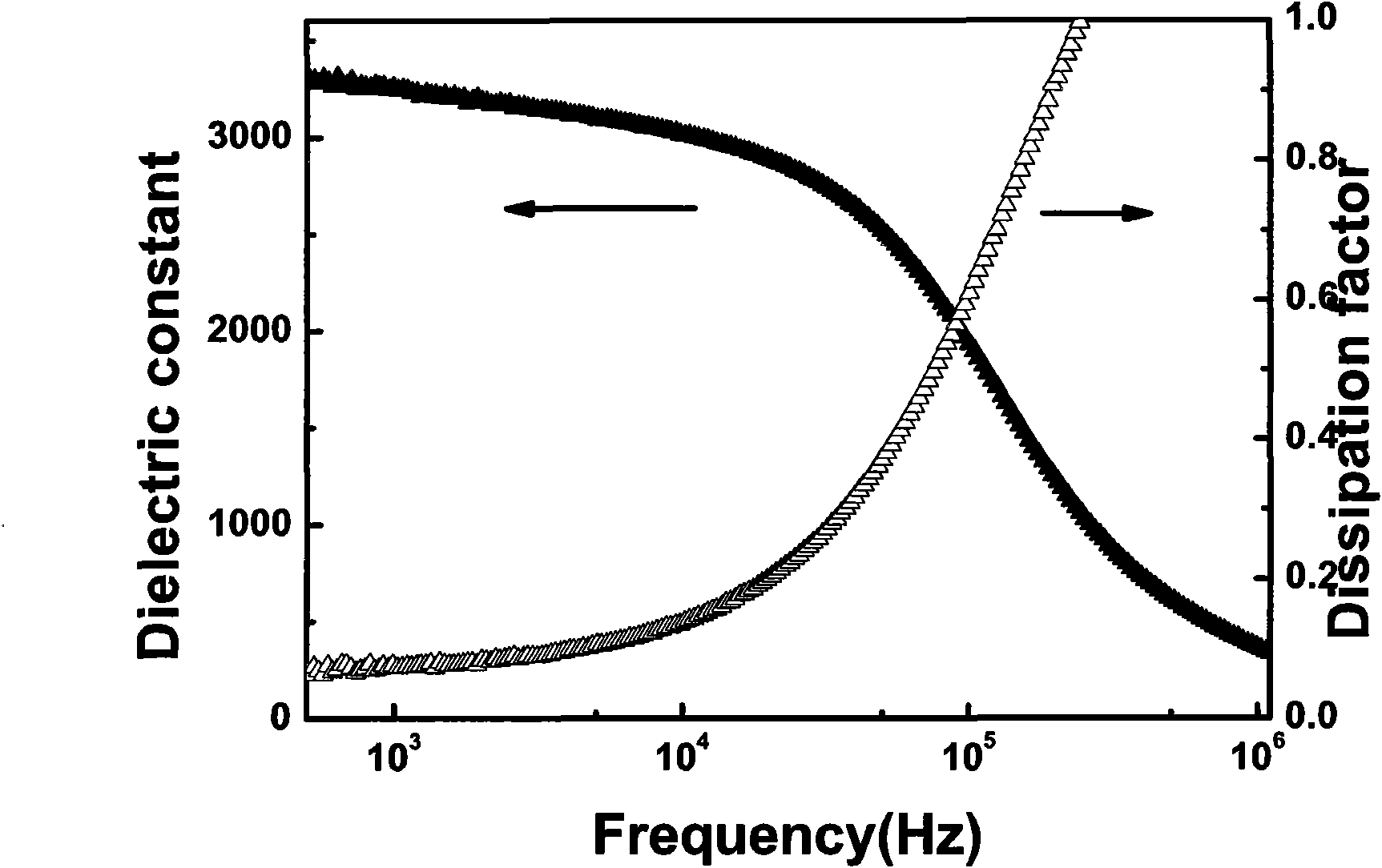

[0018] In this example, the titanium lead magnesium niobate thin film is prepared by plasma oxygen plasma assisted pulsed laser deposition method, and the specific process steps are as follows:

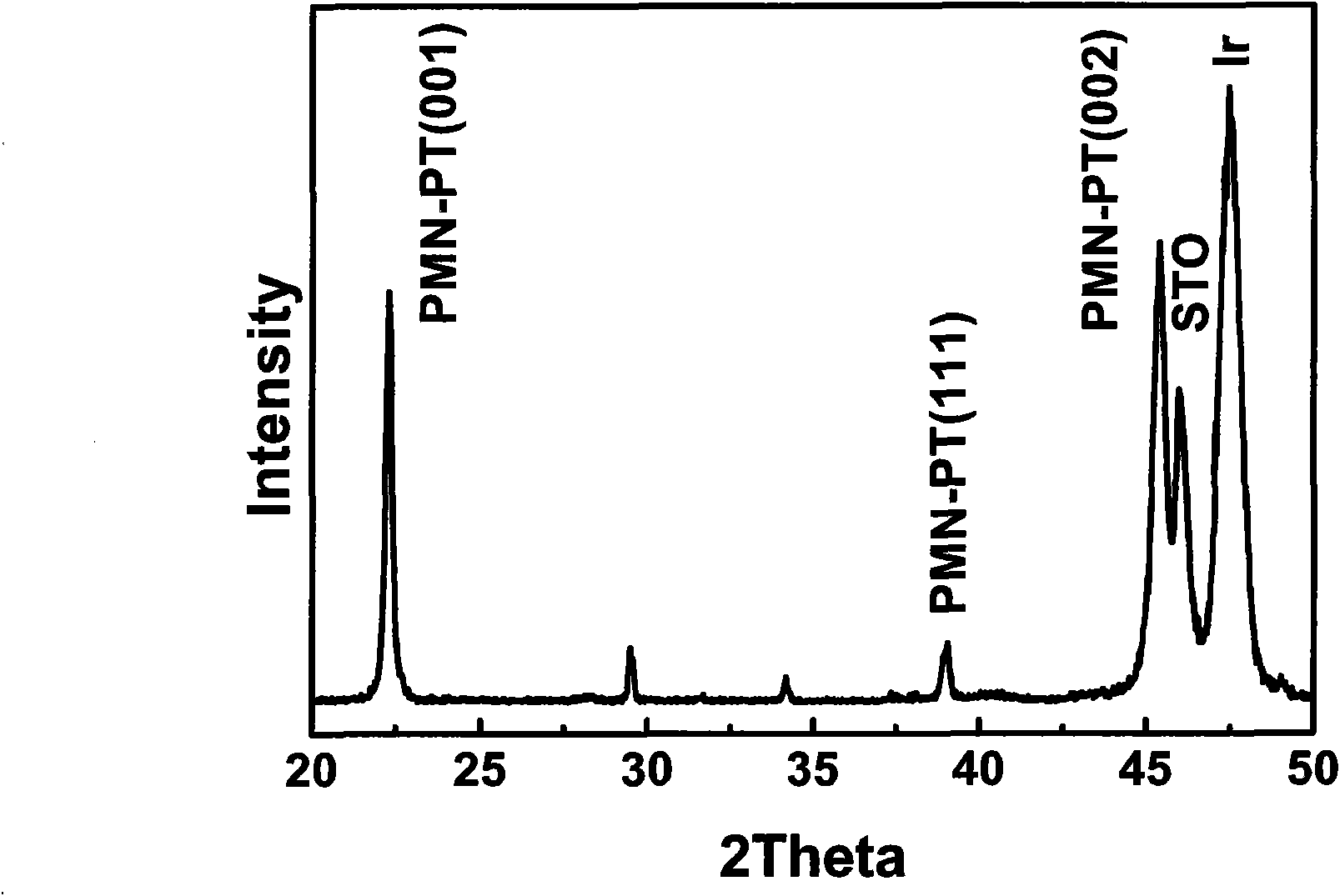

[0019] a) Target preparation: choose 0.67Pb(Mg 1 / 3 Nb 2 / 3 )O 3 -0.33PbTiO 3 Ceramics are used as the target material, and the target material is polished to a flat surface, then ultrasonically cleaned in a mixed solution of ethanol and deionized water, dried and placed in a vacuum chamber.

[0020] b) Substrate preparation: ultrasonic cleaning of epitaxial Ir / SrTiO with a mixed solution of ethanol and deionized water 3 / Si(100) substrate, rinse the surface with deionized water, then dry it with nitrogen and place it in a vacuum chamber. Vacuum to higher than 3×10 -4 Pa, heating the substrate to a temperature of 650°C.

[0021] c) Preparation of titanium niobate lead magnesium oxide film: Fill high-purity oxygen into the vacuum chamber, adjust the oxygen partial pressure to 2Pa, ...

Embodiment 2

[0025] In this example, the titanium lead magnesium niobate thin film is prepared by plasma oxygen plasma assisted pulsed laser deposition method, and the specific process steps are as follows:

[0026] a) Target preparation: choose 0.85Pb(Mg 1 / 3 Nb 2 / 3 )O 3 -0.15PbTiO 3 The thin film uses a single crystal as the target material, and puts it into a vacuum chamber after cleaning and drying.

[0027] b) Substrate preparation: Ultrasonic cleaning with a mixed solution of ethanol and deionized water 0.5 Sr 0.5 CoO 3 The MgO single crystal substrate of the oxide thin film electrode was rinsed with deionized water, then dried with nitrogen and placed in a vacuum chamber. Vacuum until the background vacuum is 3×10 -4 Pa, heating the substrate to a temperature of 600°C.

[0028]c) Preparation of titanium niobate lead magnesium oxide thin film: Fill high-purity oxygen into the vacuum chamber, adjust the oxygen partial pressure to 5Pa, apply high pressure through the gas ionizat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Remanent polarization | aaaaa | aaaaa |

| Saturation polarization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com