Furnace capable of simultaneously producing semi coke by using small-particle coal

A technology of small particles and semi-coke, which is applied in fixed carbonization furnaces, coke ovens, special forms of dry distillation, etc., can solve the problems of gas waste, furnace stickiness, long production process, etc., and achieve strong production and processing capabilities and excellent raw material quality , the effect of high comprehensive utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

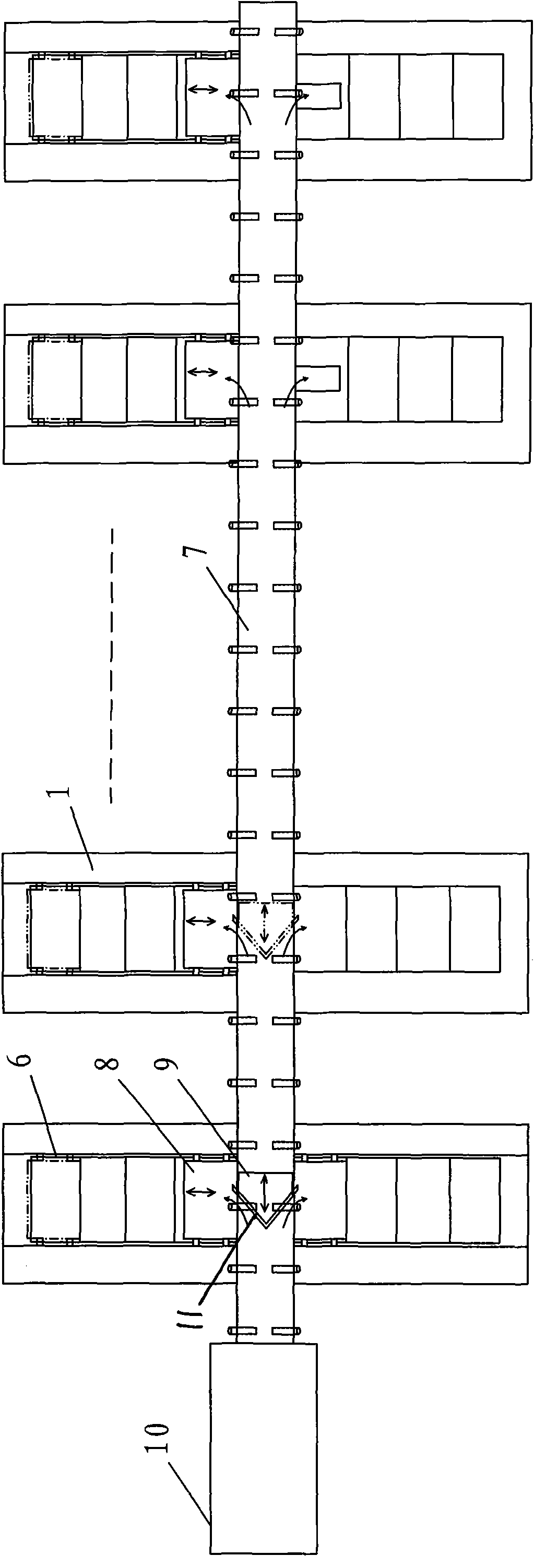

[0013] A furnace capable of simultaneously producing semi-coal from small particles of coal, such as image 3 , Figure 4 As shown, a furnace body 1 is included, and a carbonization chamber 2 is arranged in the furnace body 1. There is at least one carbonization chamber 2, and the carbonization chambers 2 are arranged side by side. The arrangement of multiple carbonization chambers is beneficial to increase the output of semi-coke per unit time, and the carbonization chamber 2 is rectangular or circular. The middle and lower parts of the carbonization chamber 2 are steel water jackets 3 connected with inlet and outlet pipes. The steel water jacket 3 is a water jacket with circulating cooling water inside. Intake pipes 4 with control valves are evenly distributed and communicated. Said air intake pipe 4 links to each other with oxygen delivery pipe. During operation, combustion-supporting oxygen is blown into the carbonization chamber 2 through the intake pipe 4, and the flo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com