Method for preparing disodium 5'-ribonucleotide

A technology of nucleotide disodium and nucleoside phosphodiester, which is applied in the fields of food and medicine, can solve the problems of large screening workload and limited scope of substrate action, and achieves reduced post-processing difficulty, fewer impurities and fewer by-products. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

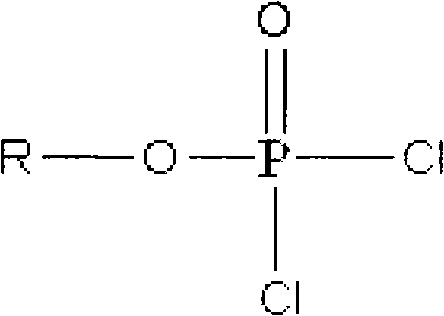

[0026] Preparation of tert-butoxyphosphoryl dichloride

[0027] Add 30.7g of phosphorus oxychloride and 30ml of dichloromethane into a 100ml reaction flask, cool to below 0°C, add 22.2g of tert-butanol dropwise, then naturally warm up to room temperature and react for 3 hours, first evaporate the solvent under reduced pressure, and then 36.4 g of tert-butoxyphosphoryl dichloride were evaporated under reduced pressure with an oil pump, with a yield of 95.1%.

Embodiment 2

[0029] Synthesis of 5'-guanosine phosphodiester

[0030] Add 40.0 g of tert-butoxyphosphoryl dichloride and 400 ml of dichloromethane into a 1000 ml reaction flask in Example 1, cool to below 0° C., and add 56.6 g of guanosine under nitrogen protection, then add 12 ml of triethylamine, and then Raise the temperature and react at 20-50°C for 5 hours. The reaction was poured into ice water, the organic layer was separated, the aqueous layer was extracted once more with 200ml of dichloromethane, the combined organic layers were washed with water, the organic layer was dried with anhydrous sodium sulfate, filtered, and the solvent was evaporated under reduced pressure. Vacuum-dried to obtain 86.5 g of 5'-guanosine phosphodiester with a yield of 96.8%.

Embodiment 3

[0032] Synthesis of disodium 5'-guanylate

[0033] Add 83.8g of 5'-phosphodiester of guanosine and 1200ml of methanol in Example 2 into a 2000ml reaction flask, pass in an appropriate amount of dry hydrogen chloride gas, then raise the temperature at 20-50°C for 4 hours, and then add sodium hydroxide Solution, neutralization, salt formation, cooling, solid precipitation, filtration, and vacuum drying to obtain 102.6 g of disodium 5'-guanylate with a yield of 96.2% and a purity of 98.3%.

[0034] Above-mentioned embodiment all uses high performance liquid chromatograph purity analysis, and its condition is as follows:

[0035] Instrument: high performance liquid chromatography (Agilent 1200)

[0036] Column: BDS C18 4.6mmx250mm

[0037] Mobile phase: 0.5% potassium dihydrogen phosphate solution

[0038] Flow rate: 1.2ml / sec

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com