Method for vibrating, fluidizing and decomposing phosphogypsum

A phosphogypsum and fluidization technology, which is applied in chemical instruments and methods, inorganic chemistry, sulfur compounds, etc., can solve the problems of material sintering and affecting production continuity, so as to prevent agglomeration and facilitate the reduction of sulfuric acid production cost. The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for vibrating fluidized decomposition of phosphogypsum, comprising the steps of:

[0025] 1) Phosphogypsum pretreatment: Dry phosphogypsum at 120°C for 2 hours to remove free water, then dry at 650°C (dry for 2 hours), remove crystal water, crush, and pass through an 80-mesh sieve to obtain Phosphogypsum powder, the particle size of the phosphogypsum powder is 10-50 microns;

[0026] 2) Preparation of composite admixture: according to the mass percentage of each component: SiO 250%, Fe 2 o 3 10%, CaO 20%, MgO 5%, Al 2 o 3 15%, select SiO 2 , Fe 2 o 3 , CaO, MgO and Al 2 o 3 ; Each component is passed through 80 mesh sieve; SiO 2 , Fe 2 o 3 , CaO, MgO and Al 2 o 3 Mix to obtain a composite admixture;

[0027] 3) Take 500g of the above-mentioned phosphogypsum powder, and mix the composite admixture and the phosphogypsum powder evenly in a mass ratio of 1:7 to obtain a mixture;

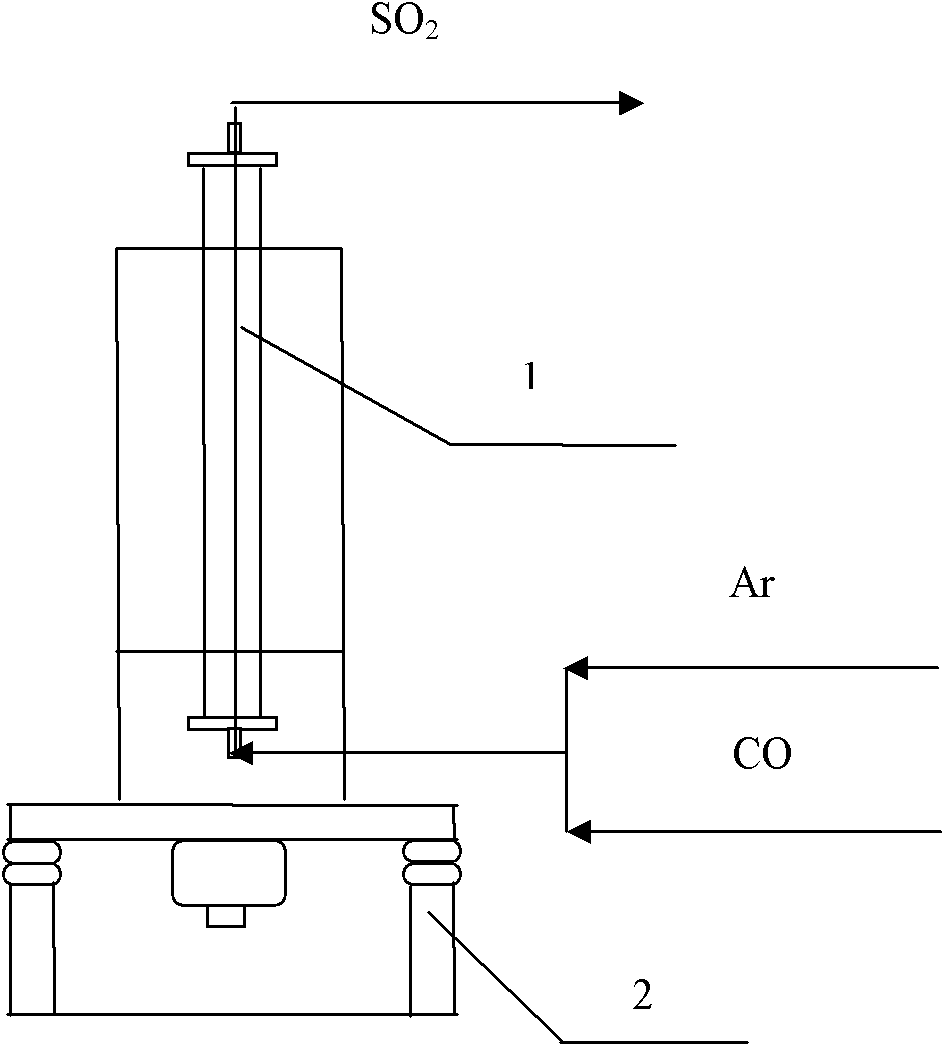

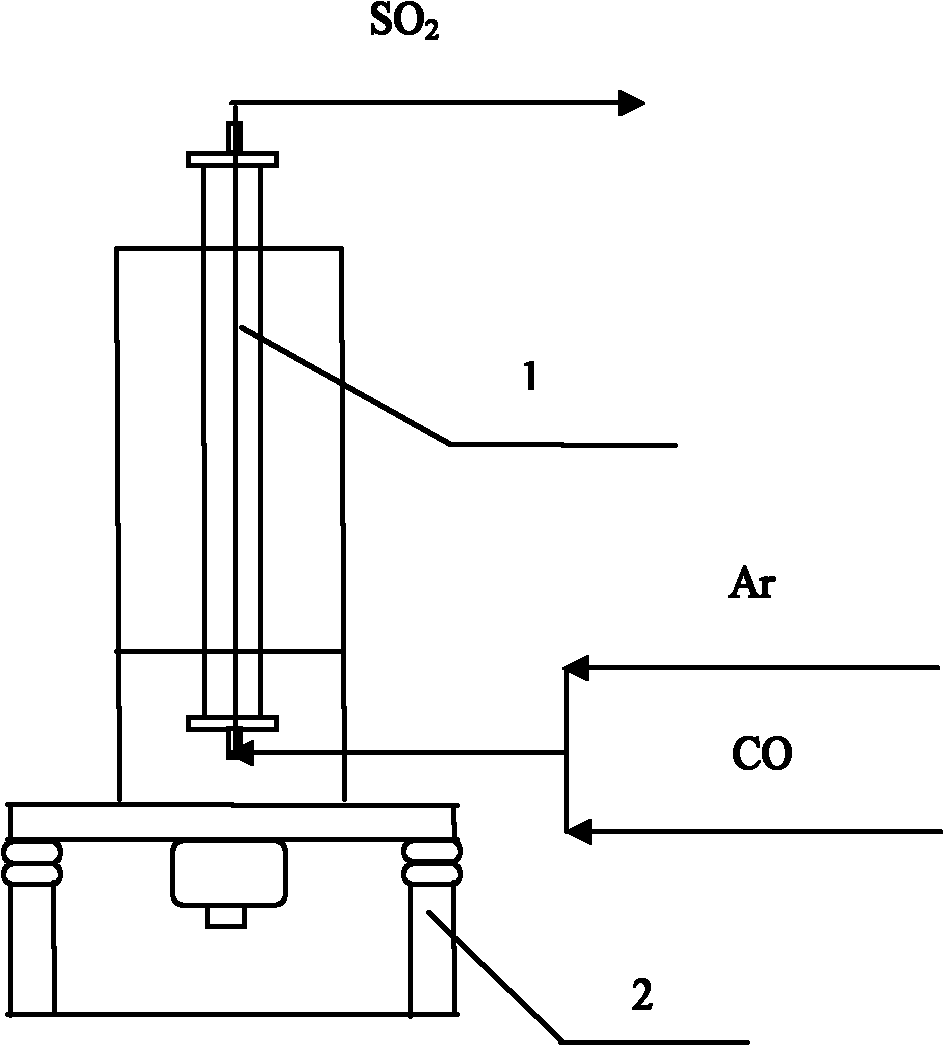

[0028] 4) Equipment preparation: such as figure 1 As shown, the un...

Embodiment 2

[0032] A method for vibrating fluidized decomposition of phosphogypsum, comprising the steps of:

[0033] 1) Phosphogypsum pretreatment: Dry phosphogypsum at 120°C for 2 hours to remove free water, then dry at 650°C (dry for 2 hours), remove crystal water, crush, and pass through an 80-mesh sieve to obtain Phosphogypsum powder, the particle size of the phosphogypsum powder is 10-50 microns;

[0034] 2) Preparation of composite admixture: according to the mass percentage of each component: SiO 2 60%, Fe 2 o 3 10%, CaO 10%, MgO 5%, Al 2 o 3 15%, the sum of the mass percentages of each component is 100%, choose SiO 2 , Fe 2 o 3 , CaO, MgO and Al 2 o 3 ; Each component is passed through 80 mesh sieve; SiO 2 , Fe 2 o 3 , CaO, MgO and Al 2 o 3 Mix to obtain a composite admixture;

[0035] 3) Take 500g of phosphogypsum powder, mix the composite admixture and phosphogypsum powder evenly in a mass ratio of 1:7, and obtain a mixture;

[0036] 4) Equipment preparation:...

Embodiment 3

[0040] A method for vibrating fluidized decomposition of phosphogypsum, comprising the steps of:

[0041] 1) Phosphogypsum pretreatment: Dry phosphogypsum at 120°C for 2 hours to remove free water, then dry at 650°C (dry for 2 hours), remove crystal water, crush, and pass through an 80-mesh sieve to obtain Phosphogypsum powder, the particle size of the phosphogypsum powder is 10-50 microns;

[0042] 2) Preparation of composite admixture: according to the mass percentage of each component: SiO 2 40%, Fe 2 o 3 20%, CaO 20%, MgO 10%, Al 2 o 3 10%, select SiO 2 , Fe 2 o 3 , CaO, MgO and Al 2 o 3 ; Each component is passed through 80 mesh sieve; SiO 2 , Fe 2 o 3 , CaO, MgO and Al 2 o 3 Mix to obtain a composite admixture;

[0043] 3) Take 500g of phosphogypsum powder, mix the composite admixture and phosphogypsum powder evenly in a mass ratio of 1:7, and obtain a mixture;

[0044] 4) Preparation of equipment: Set the uniform fluidized decomposition furnace 1 outs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com