Bulk amorphous alloys of Zr-Cu-Al-Be series and preparation method thereof

A zr-cu-al-be, amorphous alloy technology, applied in the field of Zr-Cu-Al-Be bulk amorphous alloy and its preparation, can solve the problem of limited application, small supercooled liquid phase region, superplasticity Problems such as poor processing capacity, to achieve the effect of low price, cost saving, and economical efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

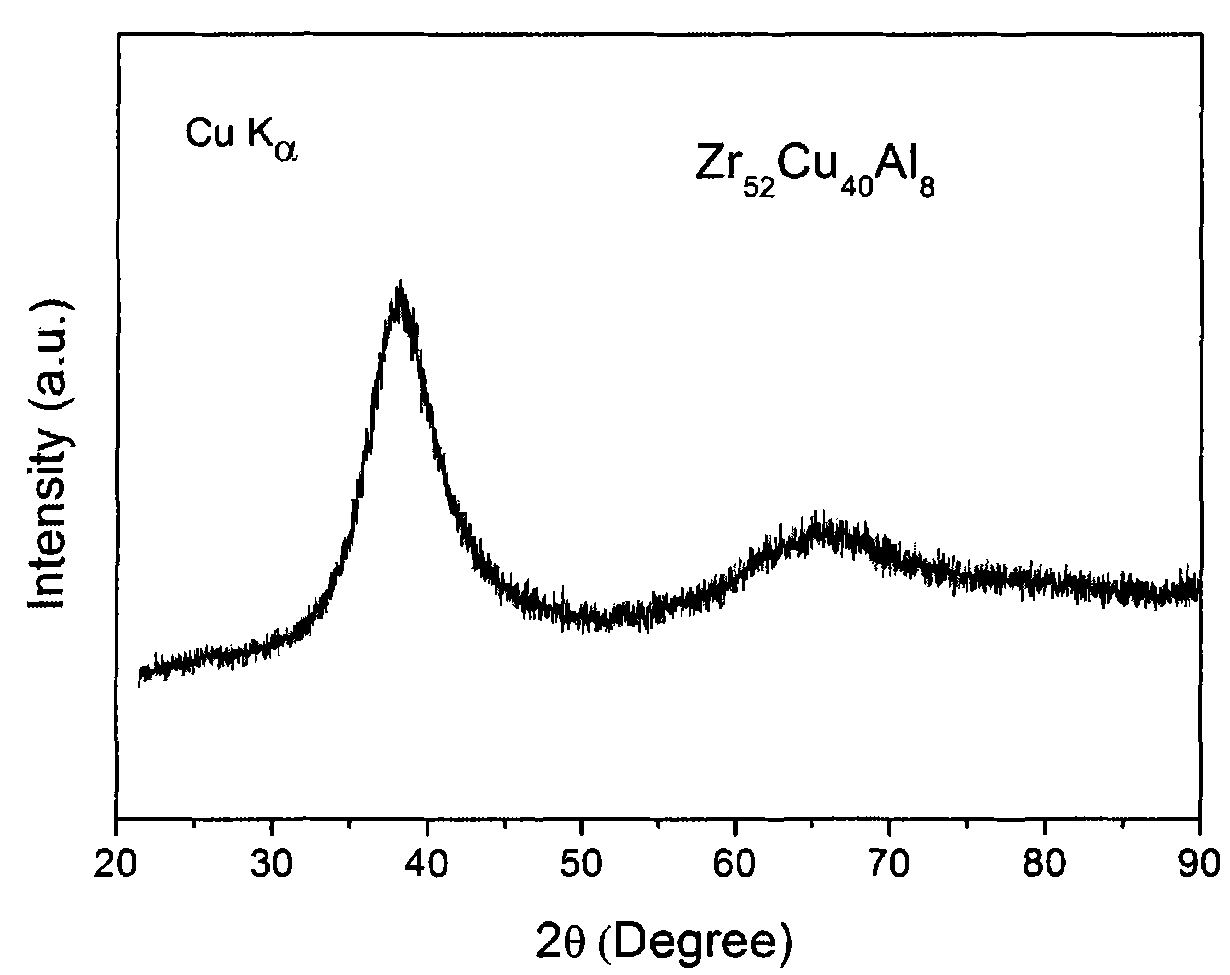

[0025] Embodiment 1: preparation Zr 52 Cu 40 Al 8 bulk amorphous alloy

[0026] Step 1: Purity 99.5wt% Zr, 99.95wt% Cu, 99.7wt% Al according to Zr 52 Cu 40 Al 8 The specified molar ratio is used for batching;

[0027] Step 2: Mix the above-mentioned ingredients and put them into an electric arc furnace, perform arc melting in an argon atmosphere adsorbed by titanium, and cool to obtain a master alloy ingot;

[0028] Step 3: re-melt the master alloy ingot obtained above under the above conditions, and use the suction casting device in the electric arc furnace to suck the master alloy melt into a water-cooled copper mold with an inner diameter of 3mm to obtain Zr 52 Cu 40 Al 8 bulk amorphous alloy.

[0029] The structural characteristics of bulk amorphous alloys were detected by X-ray diffraction (XRD). The XRD results of the alloy are as follows figure 1 shown.

[0030] The alloy was thermodynamically analyzed by differential scanning calorimetry (DSC), and the releva...

Embodiment 2

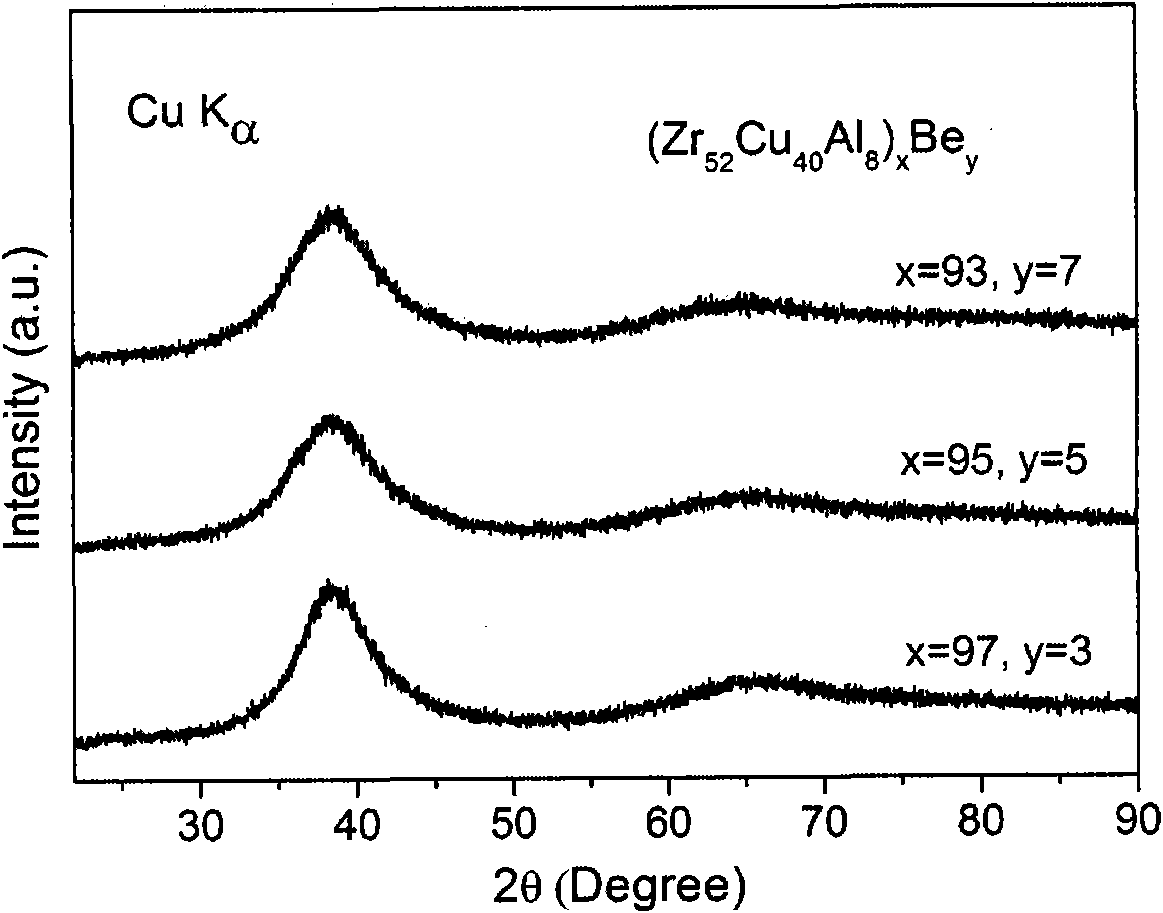

[0031] Embodiment 2: preparation (Zr 52 Cu 40 al 8 ) 97 be 3 bulk amorphous alloy

[0032] Step 1: the purity is 99.5wt% Zr, 99.95wt% Cu, 99.7wt% Al and 99.0wt% Be according to (Zr 52 Cu 40 al 8 ) 97 be 3 The specified molar ratio is used for batching;

[0033] Step 2: Mix the above-mentioned ingredients and put them into an electric arc furnace, perform arc melting in an argon atmosphere adsorbed by titanium, and cool to obtain a master alloy ingot;

[0034] Step 3: Re-melt the master alloy ingot obtained above under the above conditions, and use the suction casting device in the electric arc furnace to suck the master alloy melt into a water-cooled copper mold with an inner diameter of 6 mm to obtain (Zr 52 Cu 40 al 8 ) 97 be 3 bulk amorphous alloy.

[0035] The structural characteristics of bulk amorphous alloys were detected by X-ray diffraction (XRD). The XRD results of the alloy are as follows image 3 shown.

[0036] The alloy was thermodynamically ana...

Embodiment 3

[0036] The alloy was thermodynamically analyzed by differential scanning calorimetry (DSC), and the relevant thermodynamic parameters were obtained. The DSC curve of the alloy is as Figure 4 The specific thermodynamic parameters are shown in Table 1. Embodiment 3: preparation (Zr 52 Cu 40 al 8 ) 95 be 5 bulk amorphous alloy

[0037] Step 1: the purity is 99.5wt% Zr, 99.95wt% Cu, 99.7wt% Al and 99.0wt% Be according to (Zr 52 Cu 40 al 8 ) 95 be 5 The specified molar ratio is used for batching;

[0038] Step 2: Mix the above-mentioned ingredients and put them into an electric arc furnace, perform arc melting in an argon atmosphere adsorbed by titanium, and cool to obtain a master alloy ingot;

[0039] Step 3: re-melting the master alloy ingot obtained above under the above conditions, using the suction casting device in the electric arc furnace, sucking the master alloy melt into a water-cooled copper mold with an inner diameter of 10mm, and obtaining (Zr 52 Cu 40 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com