Preparation method of TiAlSi/TiAlSiN multilayer alternating coating with high abrasion resistance

A wear-resistant and coating technology, applied in the field of preparation of TiAlSiN coatings, can solve problems such as poor wear resistance of TiAlSiN coatings, and achieve the effects of improving wear resistance, increasing service life, and improving industrial applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

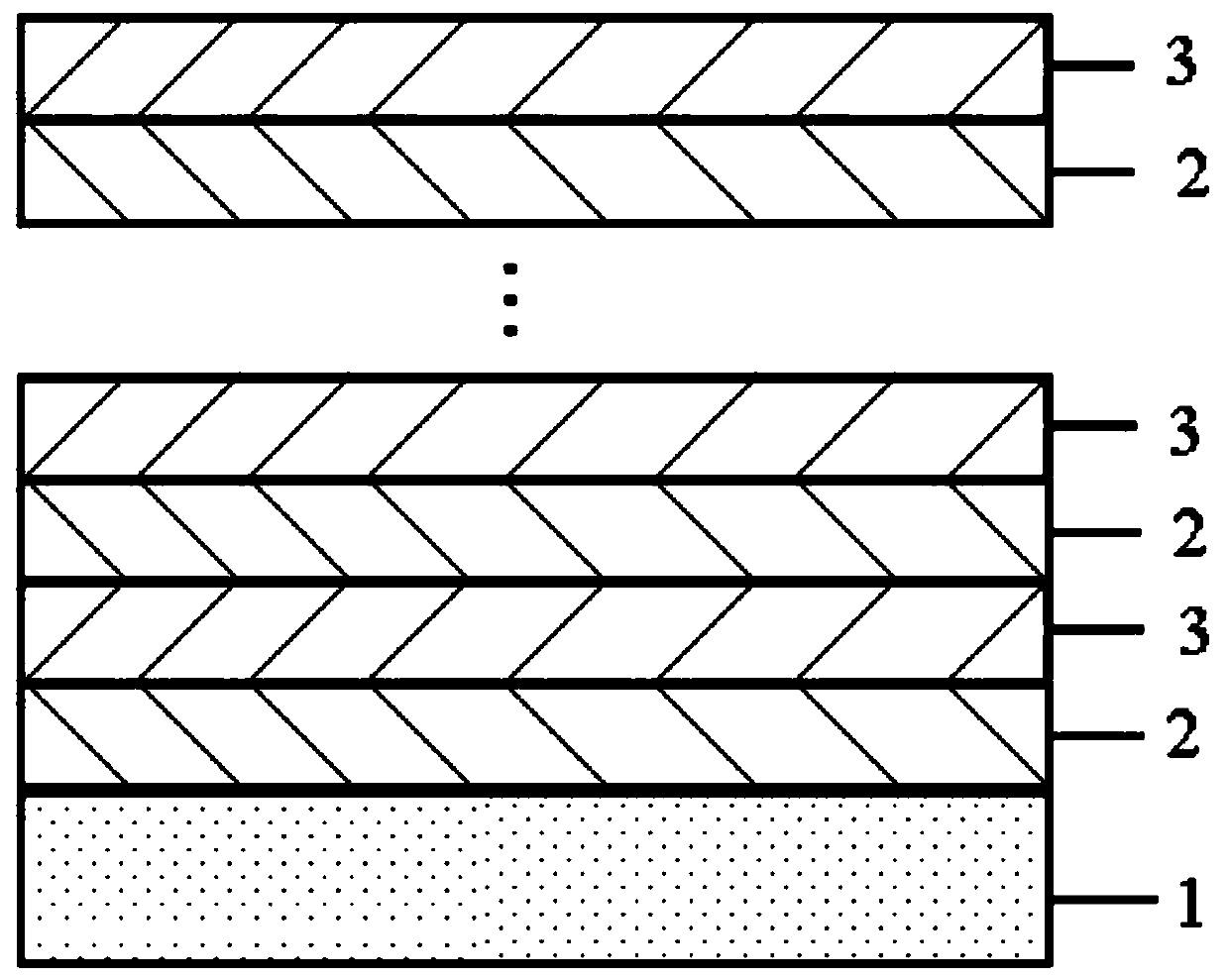

[0023] Specific Embodiment 1: This embodiment is a method for preparing a TiAlSi / TiAlSiN multi-layer alternating coating with high wear resistance, which is specifically carried out according to the following steps:

[0024] 1. Clean the substrate and install the substrate: use YG8 hard alloy as the coating substrate, polish the surface of the substrate to a mirror surface, and then use acetone and alcohol to ultrasonically clean the substrate for 10-15 minutes respectively; select plasma immersion ion implantation and deposition equipment as the coating equipment, the plasma immersion ion implantation and deposition equipment is provided with a 45 ° magnetic filter elbow and an arc source system; the substrate after cleaning is installed on the target stage of the plasma implantation and deposition equipment, and is facing the 45 ° At the outlet of the magnetic filtering elbow, the TiAlSi alloy cathode target is installed in the arc source system;

[0025] 2. Sputtering clean...

specific Embodiment approach 2

[0030] Embodiment 2: This embodiment differs from Embodiment 1 in that: in step 1, the surface of the substrate is polished to a mirror surface, and then the substrate is ultrasonically cleaned with acetone and alcohol for 10 minutes respectively. Others are the same as the first embodiment.

specific Embodiment approach 3

[0031]Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the TiAlSi alloy cathode target described in step 1 is prepared by water-cooled copper crucible melting equipment. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com