Beta titanium alloy and preparation method thereof

A technology of beta titanium alloy and alloy material, applied in the field of low cost and high strength beta titanium alloy and its preparation, can solve the problems of high price and high melting point, and achieve the effect of low cost and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

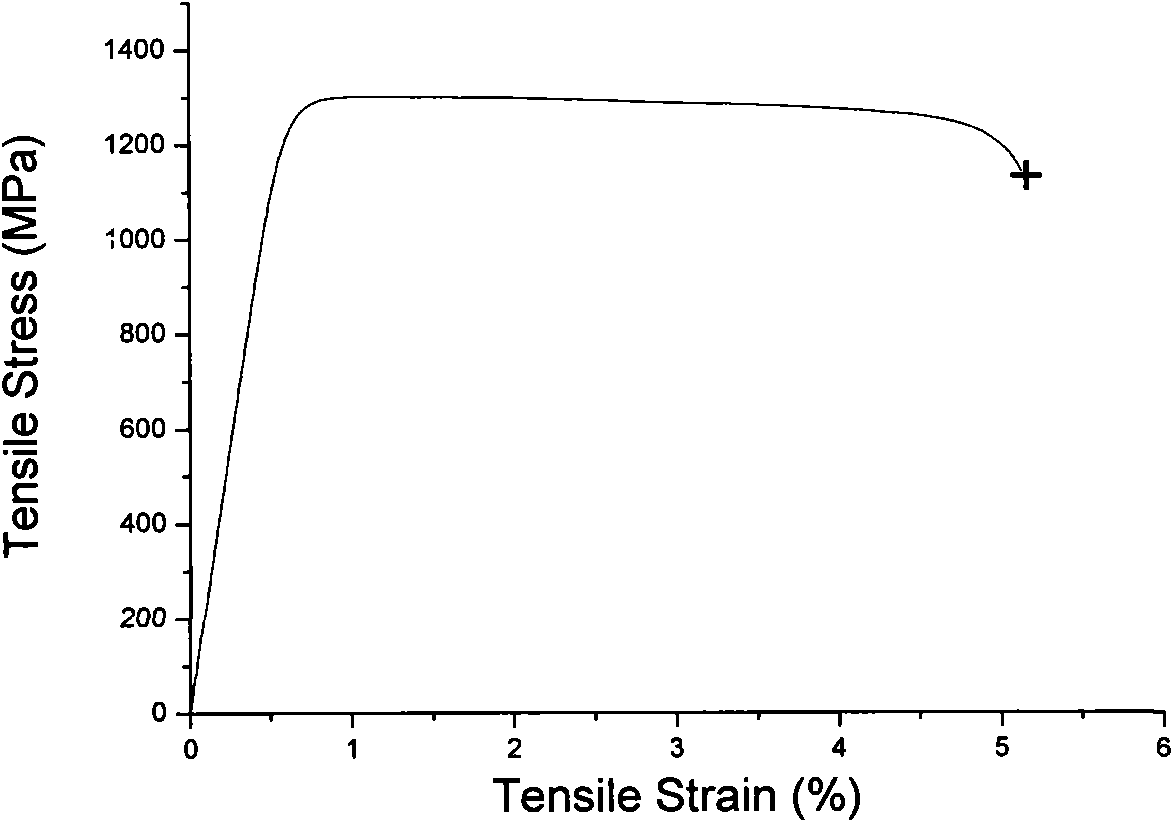

Image

Examples

Embodiment 1

[0024] Embodiment 1: Preparation of Ti-1.5Fe-2Al-4Cr-8Nb titanium alloy

[0025] Put the spongy titanium into the non-consumable vacuum electric arc furnace first, and evacuate to 5×10 -3 Pa, filled with high-purity argon to 0.7×10 5 After Pa, flip and smelt twice. Then put the high-purity iron, aluminum, chromium, niobium and previously smelted titanium into the non-consumable vacuum electric arc furnace after weighing and cleaning, and repeat the smelting for 5 times according to the previous method with magnetic stirring to obtain β titanium alloy ingot. Put the β titanium alloy ingot obtained above into a vacuum heat treatment furnace for homogenization heat treatment, and the vacuum degree is 5×10 -3 Pa, after heat treatment at 900°C for 24 hours, cool with the furnace. The heat-treated β-titanium alloy ingot is hot-rolled at 700° C., and hot-rolled into a sheet-shaped alloy material with a thickness of 1 mm. The alloy sheet obtained above was cut into dumbbell-shape...

Embodiment 2

[0027] Embodiment 2: Preparation of Ti-2.5Fe-1.5Al-2Cr-11Nb titanium alloy

[0028] Put the spongy titanium into the non-consumable vacuum electric arc furnace first, and evacuate to 5×10 -3 Pa, filled with high-purity argon to 0.7×10 5 After Pa, flip and smelt twice. Then put the high-purity iron, aluminum, chromium, niobium and previously smelted titanium into the non-consumable vacuum electric arc furnace after weighing and cleaning, and repeat the smelting for 5 times according to the previous method with magnetic stirring to obtain β titanium alloy ingot. Put the β titanium alloy ingot obtained above into a vacuum heat treatment furnace for homogenization heat treatment, and the vacuum degree is 5×10 -3Pa, after heat treatment at 1000°C for 12 hours, cool with the furnace. The heat-treated β-titanium alloy ingot is hot-rolled at 800° C., and hot-rolled into a sheet-shaped alloy material with a thickness of 1 mm. The alloy sheet obtained above was cut into dumbbell-sh...

Embodiment 3

[0030] Embodiment 3: Preparation of Ti-0.5Fe-3.5Al-3Cr-6Nb titanium alloy

[0031] Put the spongy titanium into the non-consumable vacuum electric arc furnace first, and evacuate to 5×10 -3 Pa, filled with high-purity argon to 0.7×10 5 After Pa, flip and smelt twice. Then put the high-purity iron, aluminum, chromium, niobium and previously smelted titanium into the non-consumable vacuum electric arc furnace after weighing and cleaning, and repeat the smelting for 5 times according to the previous method with magnetic stirring to obtain β titanium alloy ingot. Put the β titanium alloy ingot obtained above into a vacuum heat treatment furnace for homogenization heat treatment, and the vacuum degree is 5×10 -3 Pa, after heat treatment at 900°C for 24 hours, cool with the furnace. The heat-treated β-titanium alloy ingot is hot-rolled at 800° C., and hot-rolled into a sheet-shaped alloy material with a thickness of 1 mm. The alloy sheet obtained above was cut into dumbbell-sha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com