Barium zirconate titanate-potassium sodium niobate piezoelectric ceramics and preparation method thereof

A technology based on potassium sodium niobate and barium zirconate titanate, applied in the field of electronic ceramics, can solve problems such as poor process performance of high-performance barium titanate ceramics, and achieve the effects of low production cost, simple process flow and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

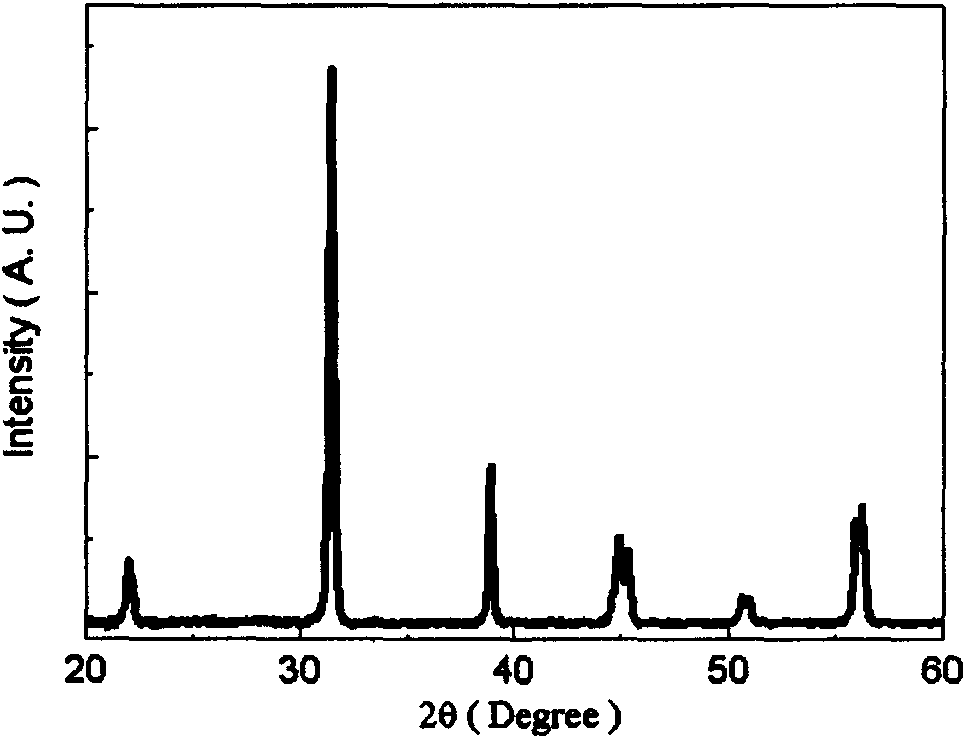

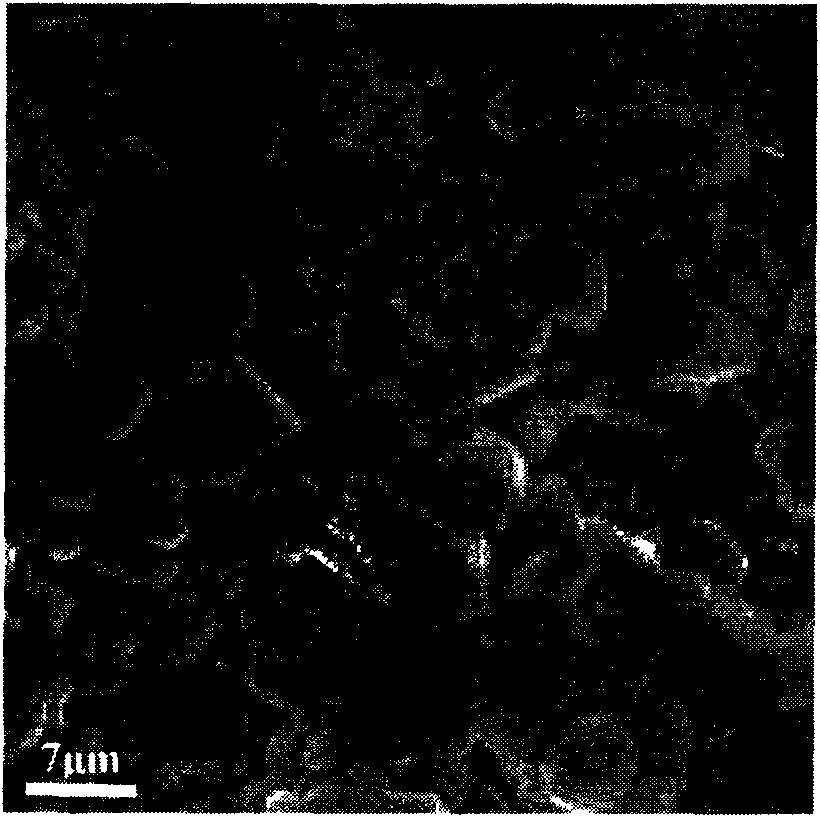

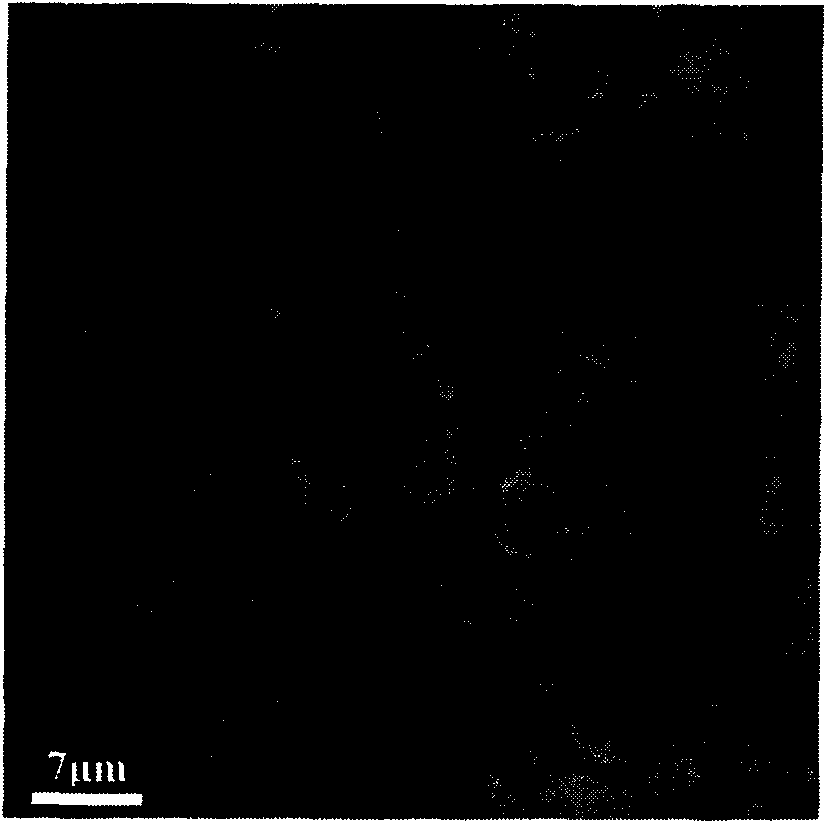

Embodiment 1

[0021] The barium carbonate whose mass percentage content is 99.9%, the sodium carbonate whose mass percentage content is 99.8%, the potassium carbonate whose mass percentage content is 99.0%, the titanium dioxide whose mass percentage content is 99.0% and the Zirconium dioxide, niobium pentoxide with a mass percentage content of 99.5%, stoichiometric ratio is 0.74K 0.5 Na 0.5 NbO 3 -0.13BaTiO 3 -0.13BaZrO 3 Weigh ingredients. Put the prepared material into the ball mill and mix according to the ratio of zirconia ball: material 10:1, and do not add other media during the mixing process. The time of ball milling is 6 hours, and the rotating speed is 400 rpm. The mixed material briquette is pre-fired at 900°C for 2 hours, the calcined material is taken out and ground, and then passed through a 40-mesh sieve after ball milling for 6 hours. The ball milling speed is 400 rev / min; add the powder to its mass ratio of 32% pure water, mass ratio of 1.2% polyacrylic acid ammonia di...

Embodiment 2

[0023] The barium carbonate whose mass percentage content is 99.9%, the sodium carbonate whose mass percentage content is 99.8%, the potassium carbonate whose mass percentage content is 99.0%, the titanium dioxide whose mass percentage content is 99.0% and the Zirconium dioxide, niobium pentoxide with a mass percentage content of 99.5%, 0.75K according to the stoichiometric ratio 0.5 Na 0.5 NbO 3 -0.15BaTiO 3 -0.10BaZrO 3Weigh ingredients. The prepared materials are put into a ball mill and mixed according to the ratio of zirconia balls:materials at 15:1, and no other medium is added during the mixing process. The time of ball milling is 6 hours, and the rotating speed is 350 rpm. The mixed material briquette is pre-fired at 1000°C for 2 hours, the calcined material is taken out and ground, and then passed through a 40-mesh sieve after ball milling for 6 hours. The ball milling speed is 350 rev / min; add the powder to its mass ratio of 30% pure water, mass ratio of 1.1% po...

Embodiment 3

[0025] The barium carbonate whose mass percentage content is 99.9%, the sodium carbonate whose mass percentage content is 99.8%, the potassium carbonate whose mass percentage content is 99.0%, the titanium dioxide whose mass percentage content is 99.0% and the Zirconium dioxide, niobium pentoxide with a mass percentage content of 99.5%, and a stoichiometric ratio of 0.74K 0.5 Na 0.5 NbO 3 -0.18BaTiO 3 -0.08BaZrO 3 Weigh ingredients. The prepared materials are put into a ball mill and mixed according to the mass ratio of zirconia balls:materials at a ratio of 8:1, and no other medium is added during the mixing process. The time of ball milling is 5 hours, and the rotating speed is 450 rev / min. The mixed material briquette is pre-fired at 1150°C for 2 hours, the calcined material is taken out and ground, and then passed through a 40-mesh sieve after ball milling for 5 hours. The ball milling speed is 450 rev / min; add the powder to its mass ratio of 40% pure water, mass rati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com