Composite lining plate of ball mill and preparation method thereof

A compound ball and mill technology, applied in the field of mechanical equipment, can solve the problems of inability to carry out large-scale industrial production, fail to meet the needs of actual use, complex preparation process, etc., achieve high wear resistance, prevent collapse, and simple manufacturing process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

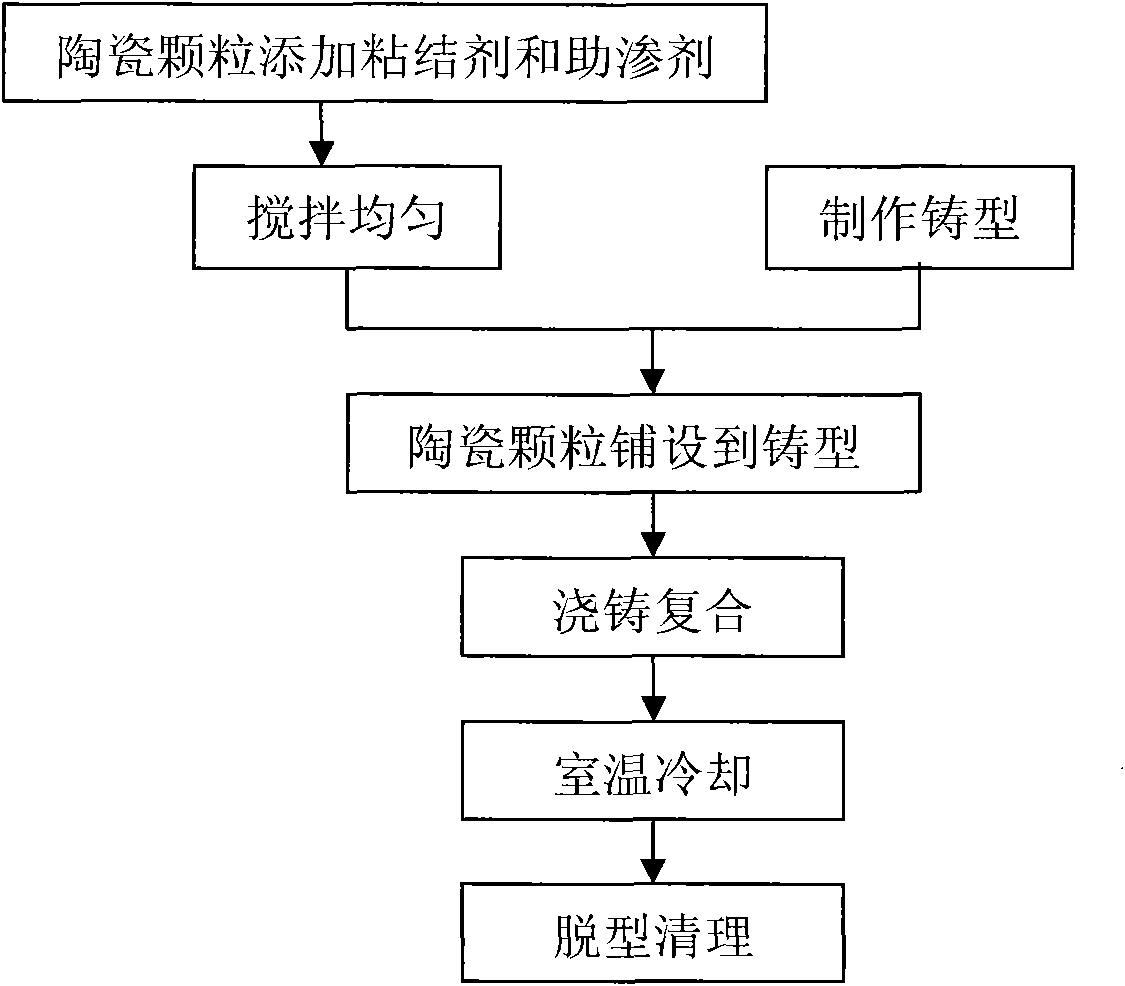

[0022] A composite ball mill liner with tungsten carbide particles as the hard phase and Mn13Mo2 high manganese steel as the matrix was prepared.

[0023] 1. Select tungsten carbide particles 1 with a particle size range of 40 to 60 mesh, add 3% furan resin and 1% borax by weight of the tungsten carbide particles, and stir evenly;

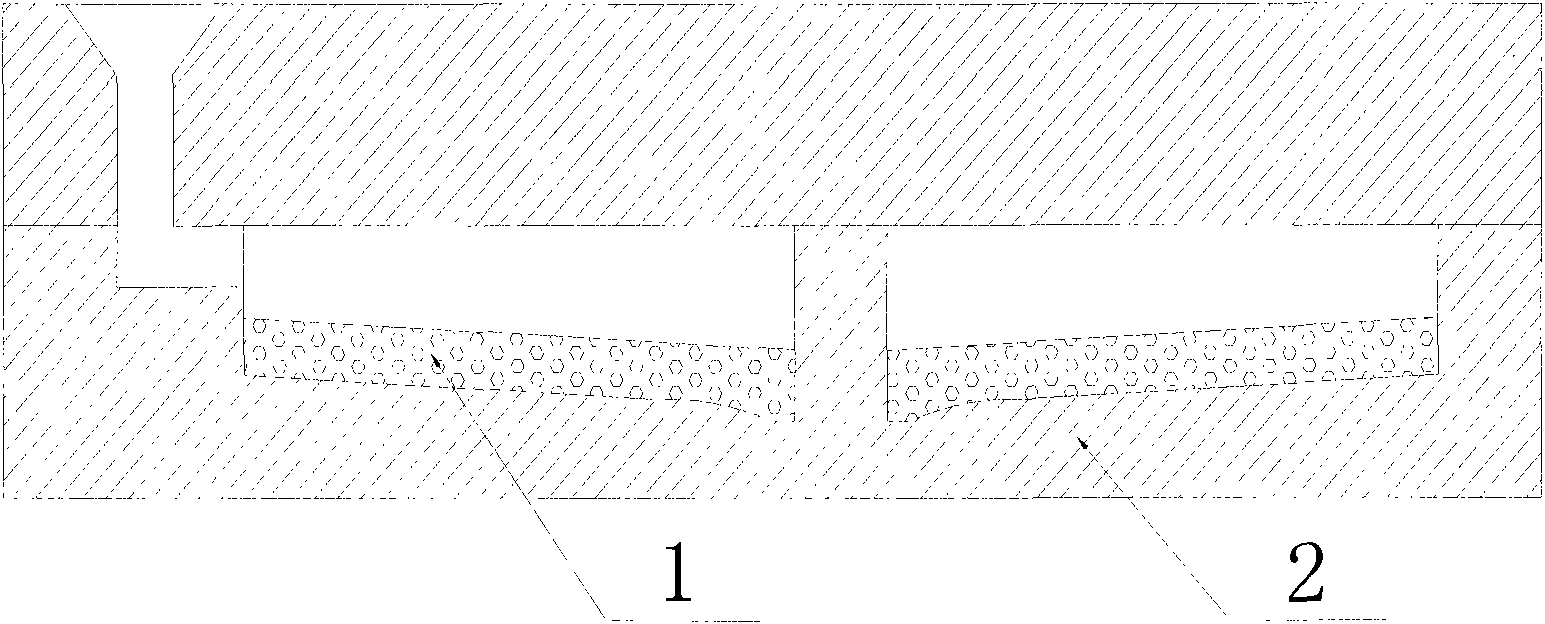

[0024] 2. Make the mold 2 according to the requirements of the casting process;

[0025] 3. Lay the stirred tungsten carbide particles 1 to a thickness of 2 mm in the cavity of the mold 2 and compact them properly;

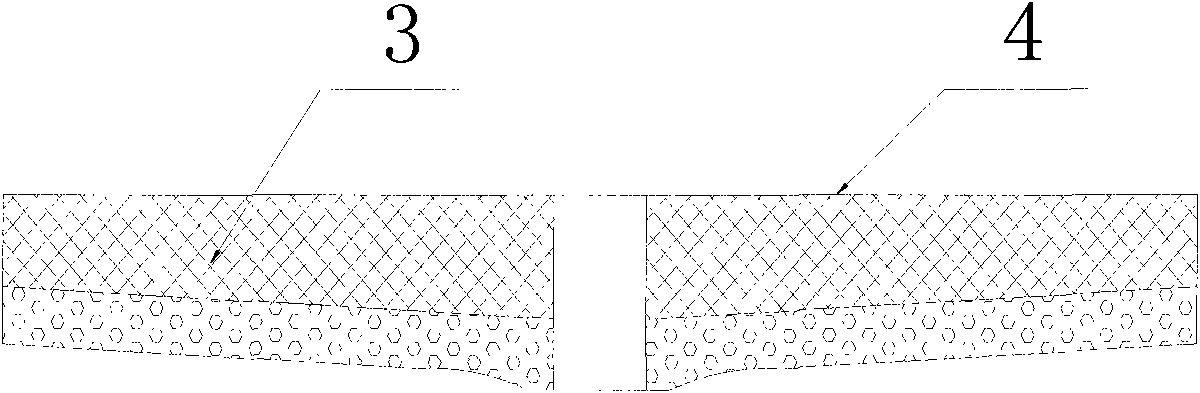

[0026] 4. Select Mn13Mo2 high manganese steel as the base metal 3. After smelting and melting in an intermediate frequency furnace, it reaches 1600°C and is released from the furnace. Pour Mn13Mo2 high manganese steel liquid into the cavity of the mold 2 until it is full;

[0027] 5. After the molten metal is cooled and solidified, take out the casting and clean it, and then make the liner 4 of the composite ball mill with tungsten ca...

Embodiment 2

[0029] A composite ball mill liner with silicon carbide particles as the hard phase and Mn13 high manganese steel as the matrix was prepared.

[0030] 1. Select silicon carbide particles 1 with a particle size range of 20 to 40 mesh, add 2% furan resin and 0.5% borax by weight of the silicon carbide particles, and stir evenly;

[0031] 2. Make the mold 2 according to the requirements of the casting process;

[0032] 3. Lay the stirred silicon carbide particles 1 to a thickness of 10mm in the cavity of the mold 2, and compact them properly;

[0033] 4. Select Mn13 high manganese steel as the base metal 3. After smelting and melting in an intermediate frequency furnace, it is released at 1600°C. Pour the Mn13 high manganese steel liquid into the cavity of the mold 2 until it is full;

[0034] 5. After the molten metal is cooled and solidified, take out the casting and clean it, and then make the liner 4 of the composite ball mill with tungsten carbide particles on the working s...

Embodiment 3

[0036] A composite ball mill liner with silicon nitride (or titanium nitride) particles as the hard phase and Mn13Mo2 high manganese steel as the matrix was prepared.

[0037] 1. Select silicon nitride (or titanium nitride) particles 1 with a particle size range of 60 to 80 meshes, add 5% furan resin and 1.5% borax by weight of the silicon nitride particles, and stir evenly;

[0038] 2. Make the mold 2 according to the requirements of the casting process;

[0039] 3. Lay the stirred silicon nitride (or titanium nitride) particles 1 to 6 mm in the cavity of the mold 2, and compact them properly;

[0040] 4. Select Mn13Mo2 high manganese steel as the base metal 3. After smelting and melting in an intermediate frequency furnace, it reaches 1600°C and is released from the furnace. Pour Mn13Mo2 high manganese steel liquid into the cavity of the mold 2 until it is full;

[0041] 5. After the molten metal is cooled and solidified, take out the casting and clean it, and then make the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com