Preparation method of stainless steel surface copper-silver diffusion coating layer

A technology of stainless steel and permeable coating, which is applied in the direction of coating, sputtering plating, ion implantation plating, etc., can solve the problems of high energy and raw material consumption, unsustainable antibacterial effect, complicated follow-up process, etc., and shorten the sterilization time , easy quality control, good process repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

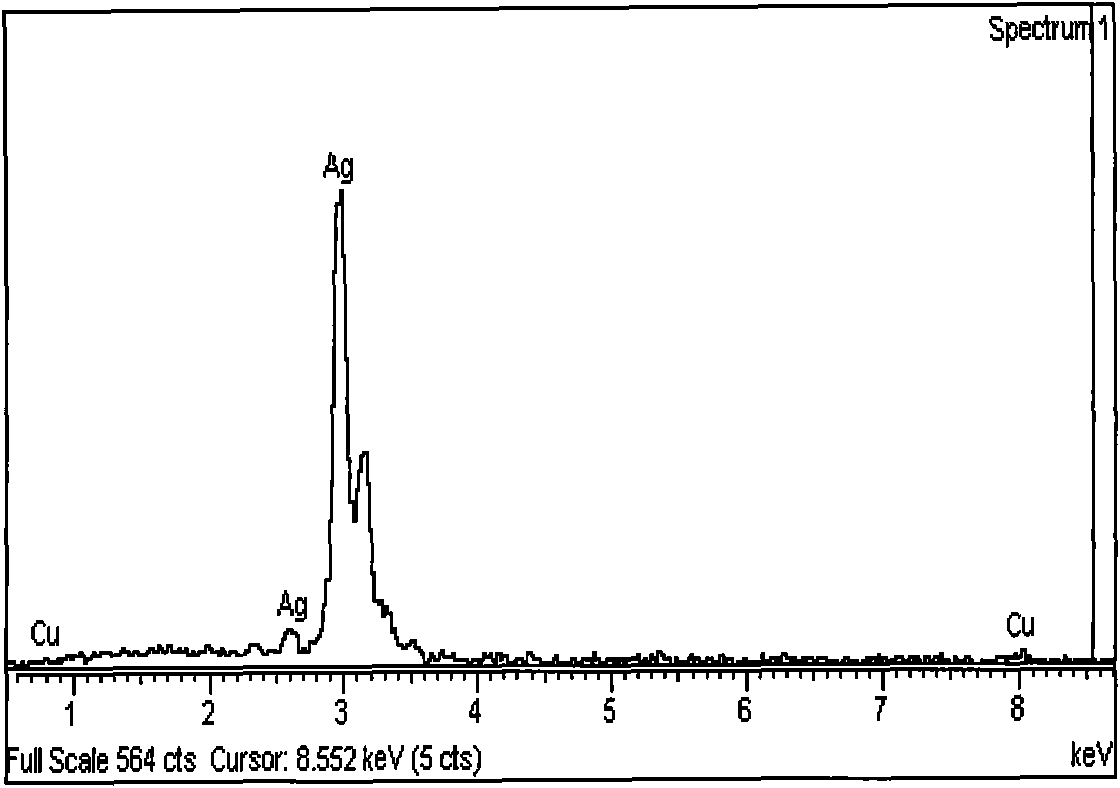

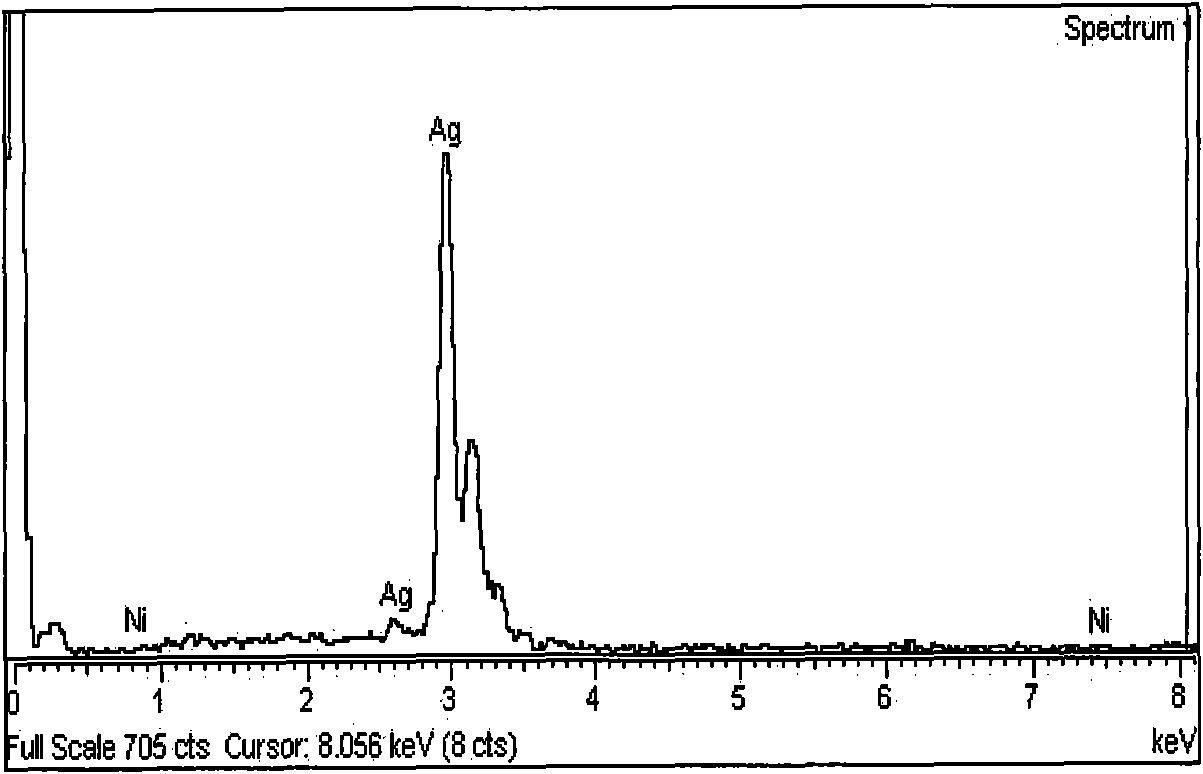

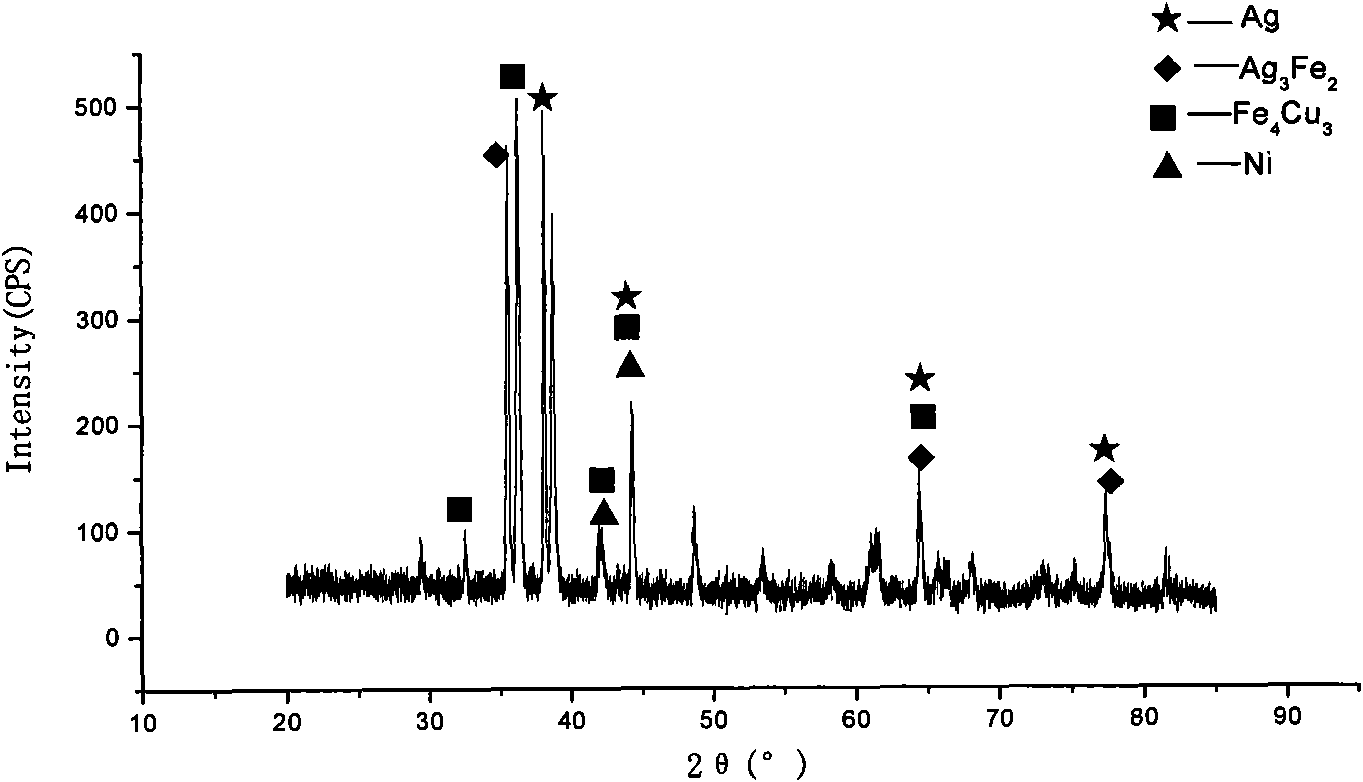

[0027] The present invention claims to prepare a copper-silver coating on the surface of stainless steel. The method has been tested with OCr18Ni9 type austenite, 1Cr13 type martensite and 1Cr17 type ferritic stainless steel. Taking the stainless steel as an example, the method is carried out according to the following steps:

[0028] 1. Double-layer glow ion metal infiltration technology copper infiltration

[0029] (1) Clean the surface of OCr18Ni9 austenitic stainless steel: pass OCr18Ni9 austenitic stainless steel through 360 # Grinding with water sandpaper to remove surface burrs and ensure a better surface smoothness, then use different grades of water sandpaper and metallographic sandpaper to polish in turn, and finally polish on a polishing cloth to ensure a better surface finish, and finally wash and dry.

[0030] (2) Furnace loading: Place OCr18Ni9 type austenitic stainless steel in a double-layer glow ion infiltration metal furnace, use a copper plate with a purity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com