Transparent EVA heat insulating material and preparation method thereof

A thermal insulation material and transparent technology, applied in the direction of adhesive additives, non-polymer adhesive additives, adhesives, etc., can solve the problems of thermal insulation, transparency and adhesion, and achieve high visible light transmission Satisfactory efficiency, transparency, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

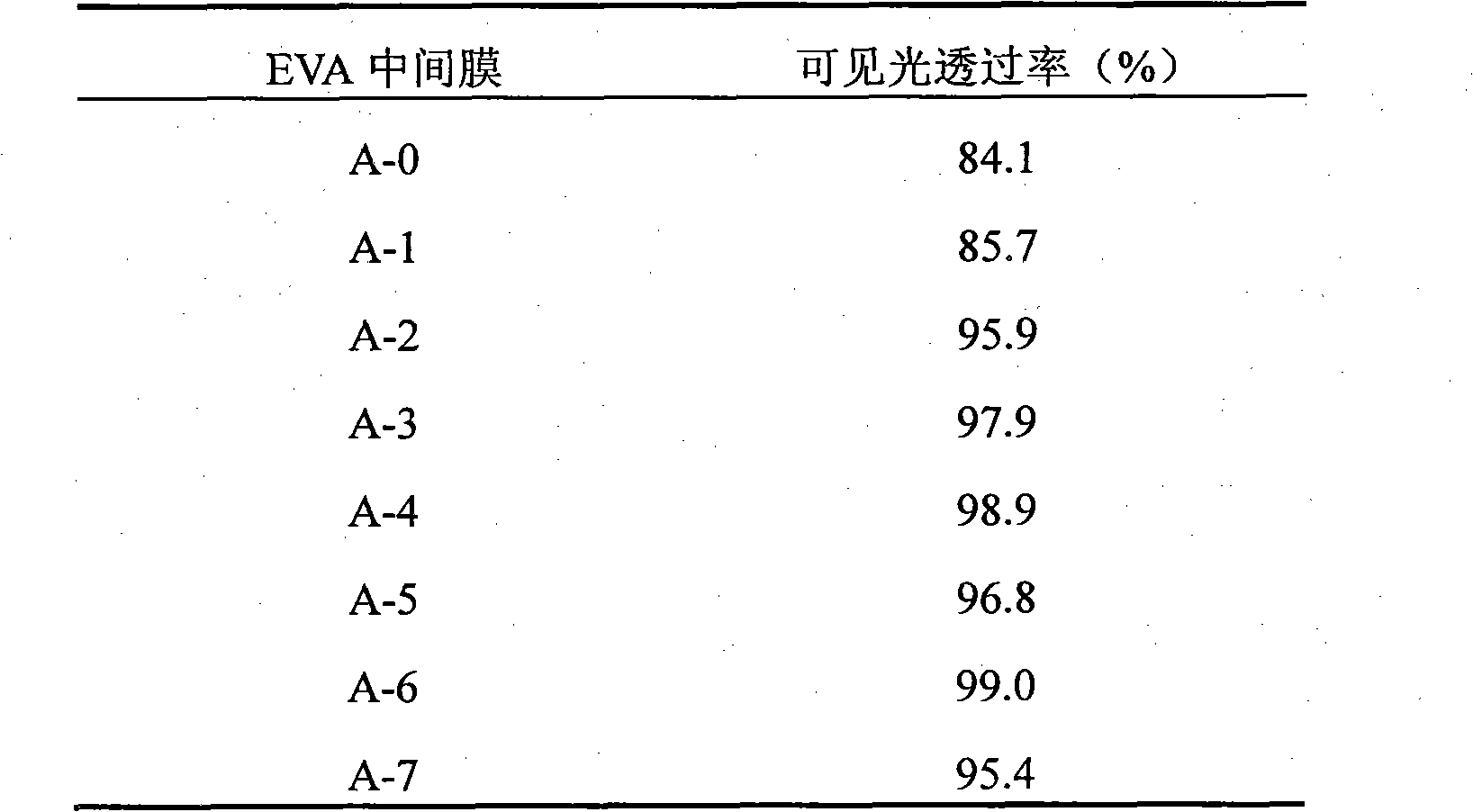

[0027] In terms of parts by mass, 0.3 parts of tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester as an antioxidant, 0.2 parts of 2,5-dimethyl-2 , 5-two (tert-butyl peroxy) hexane joins 100 parts of VA weight content as 33% EVA pellets (ethylene-vinyl acetate copolymer) as cross-linking curing agent and mix uniformly. The mixture is blended and extruded with an extruder, and the temperature is controlled at 90°C. Then the extruded product was remelted and molded, and the temperature was controlled at 145°C and the pressure was 15MPa to obtain the EVA interlayer film A-0 with a thickness of 0.5mm. Then the heat insulation experiment, thermal conductivity, light transmittance and adhesion of EVA interlayer film A-0 were carried out respectively.

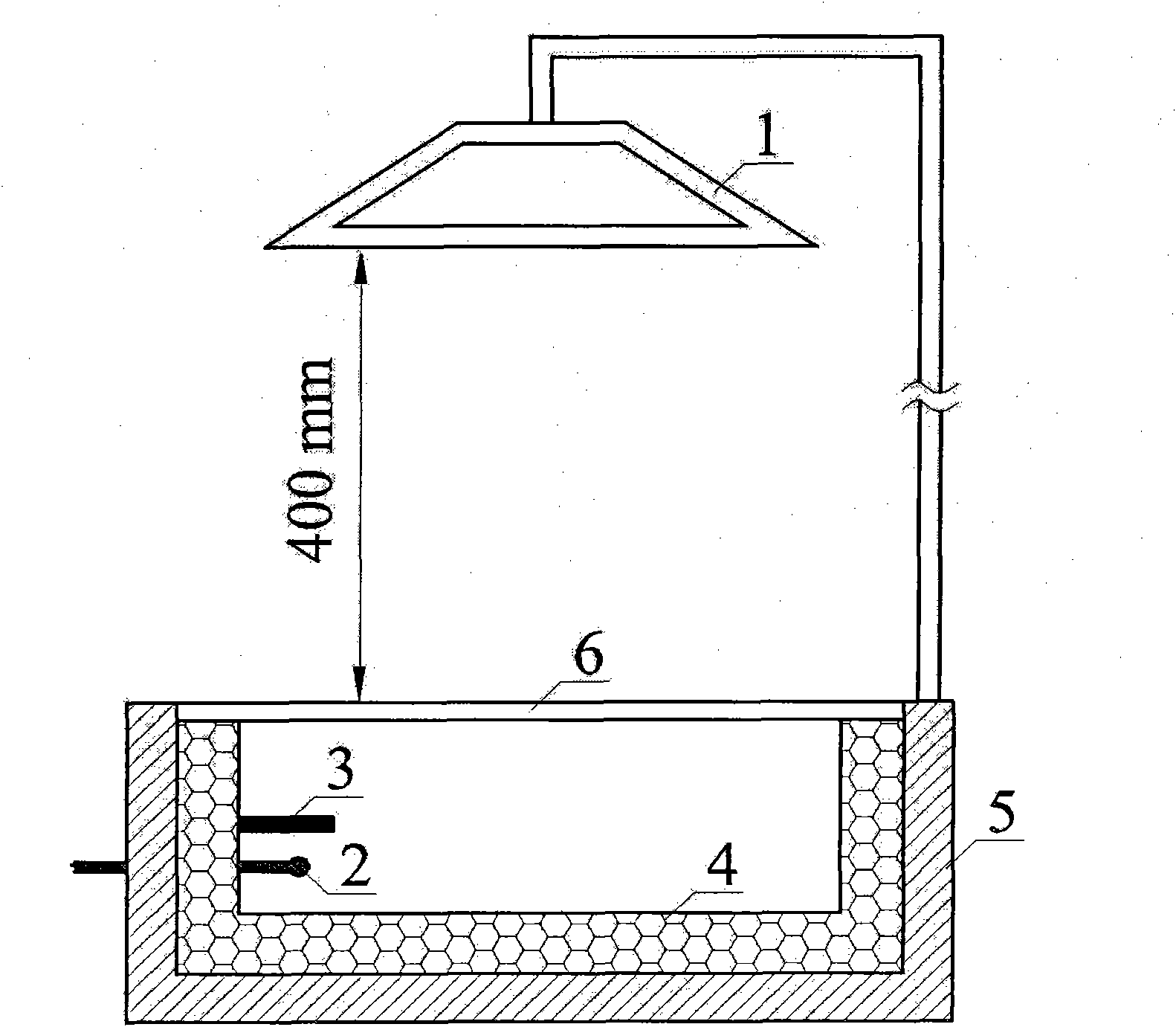

[0028] Such as figure 1 As shown, the EVA interlayer A-0 was tested by the heat shield test method. The test device for the heat insulation box test method includes a 250W infrared light source 1, a the...

Embodiment 2

[0037]In terms of parts by mass, the specific surface area of 6 parts is 150m 2 / g of nano-silica (surface treated with 3 parts of γ-aminopropyltriethoxysilane) as a thermal insulation modifier, 0.2 parts of triethylene glycol bis[β-(3-tert-butyl- 4-hydroxyl-5-methylphenyl) propionate] as antioxidant, 1.0 parts of tert-butyl peroxide cumene as cross-linking curing agent to join 100 parts of VA weight content is the EVA pellet of 28% ( Ethylene-vinyl acetate copolymer) mixed uniformly. The mixture is blended and extruded with an extruder, and the temperature is controlled at 90°C. Then the extruded product was remelted and molded, and the temperature was controlled at 145° C. and the pressure was 15 MPa to obtain an EVA interlayer film A-1 with a thickness of 0.5 mm. Conduct heat insulation experiments, thermal conductivity, light transmittance and adhesion tests on the EVA interlayer film. Test method is the same as embodiment 1.

Embodiment 3

[0039] In terms of parts by mass, the specific surface area of 6 parts is 200m 2 / g of nano-silica (surface treated with 3 parts of γ-aminopropyltriethoxysilane) as a thermal insulation modifier, 0.2 parts of triethylene glycol bis[β-(3-tert-butyl- 4-hydroxyl-5-methylphenyl) propionate] as antioxidant, 1.0 parts of tert-butyl peroxide cumene as cross-linking curing agent to join 100 parts of VA weight content is the EVA pellet of 28% ( Ethylene-vinyl acetate copolymer) mixed uniformly. The mixture is blended and extruded with an extruder, and the temperature is controlled at 90°C. Then the extruded product was remelted and molded, and the temperature was controlled at 145° C. and the pressure was 15 MPa to obtain an EVA interlayer film A-2 with a thickness of 0.5 mm. Conduct heat insulation experiments, thermal conductivity, light transmittance and adhesion tests on the EVA interlayer film. Test method is the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesion strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com