Rigid ceramic/agarose composite microsphere and preparation method thereof

A technology of composite microspheres and ceramic microspheres, which is applied in the direction of microsphere preparation, microcapsule preparations, chemical instruments and methods, etc., can solve the problems of difficult to obtain products with high porosity, difficult control of foaming process conditions, and uneven distribution of pores. Uniformity and other issues to achieve the effect of stable structure, easy control and amplification, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

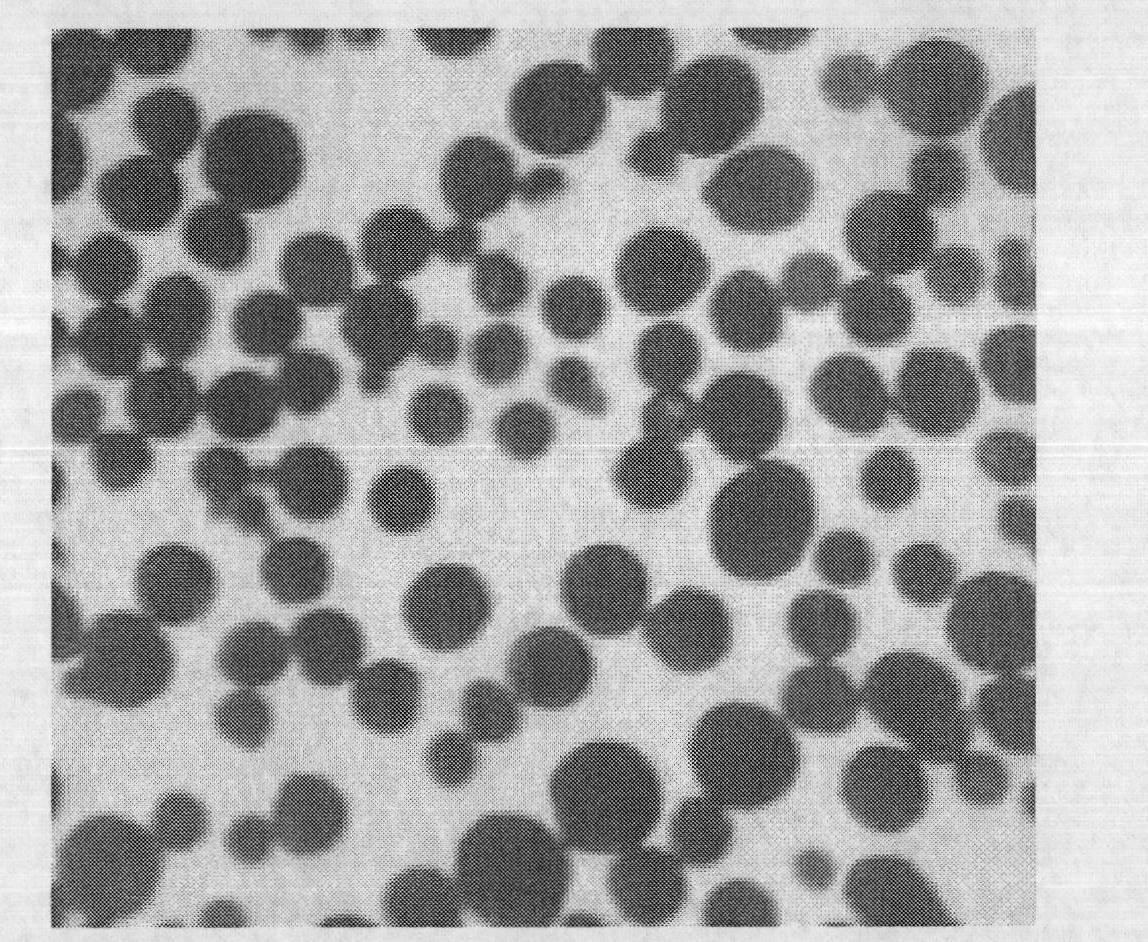

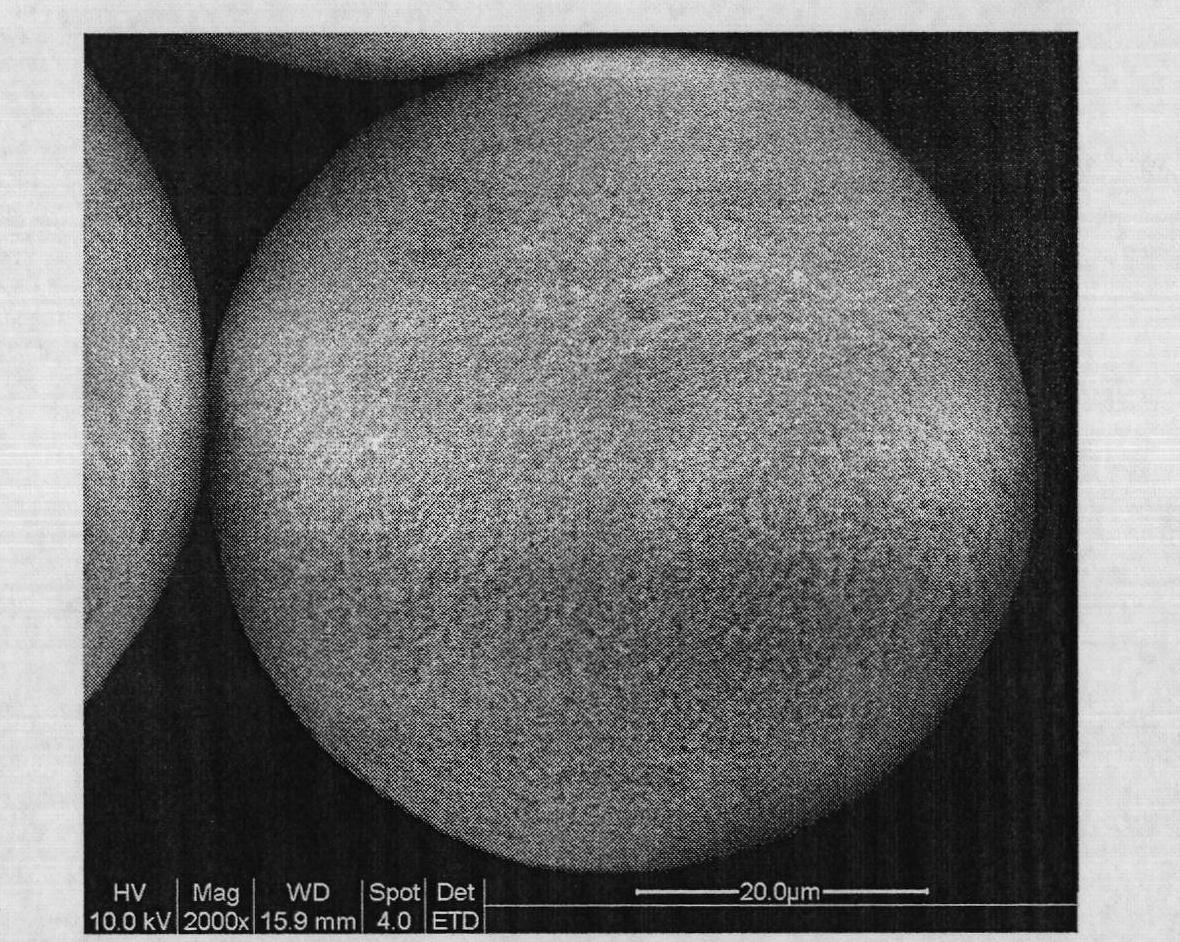

[0024] Mix 12 g of nano-silica, 2 g of citric acid, and 30 mL of water, add 20 mL of 5% sodium alginate solution and continue to stir evenly to a gel. Transfer the above ceramic slurry to a 500mL three-necked flask, add 200mL pump oil, 10mL Span 80, stir for 30min at 600rpm, add 10mL saturated calcium chloride dropwise, and continue stirring for 20min. After the reaction, the microspheres are collected by filtration, cleaned with alcohol and deionized water, dried in an oven at 60°C, heated in a muffle furnace to 1200°C, kept for 30 minutes, and cooled naturally to obtain porous ceramic microspheres. The ceramic microspheres were immersed in a 4% agarose solution, incubated at 105° C. for 30 minutes, cooled naturally, and ground with 25 mL deionized water. The water was sieved to remove the surface agarose, and the microspheres were washed with deionized water three times. The obtained rigid ceramic / agarose composite microspheres have a true wet density of 1.3 g / mL, the volume ...

Embodiment 2

[0026] Mix 12 g of nano-silica, 2 g of citric acid, and 30 mL of water, add 20 mL of 5% sodium alginate solution and continue to stir evenly to a gel. Transfer the above ceramic slurry to a 500mL three-necked flask, add 200mL pump oil, 10mL Span 80, stir for 30min at 800rpm, add 10mL saturated calcium chloride dropwise, and continue stirring for 20min. After the reaction, the microspheres are collected by filtration, cleaned with alcohol and deionized water, dried in an oven at 60°C, heated in a muffle furnace to 1200°C, kept for 30 minutes, and cooled naturally to obtain porous ceramic microspheres. The ceramic microspheres were immersed in a 4% agarose solution, incubated at 105° C. for 30 minutes, cooled naturally, and ground with 25 mL deionized water. The water was sieved to remove the surface agarose, and the microspheres were washed with deionized water three times. The obtained rigid ceramic / agarose composite microspheres have a true wet density of 1.3 g / mL, the volume ...

Embodiment 3

[0028] Mix 14 g of nano-silica, 3 g of citric acid, and 30 mL of water, add 20 mL of 5% sodium alginate solution and continue to stir evenly to a gel. Transfer the above ceramic slurry to a 500mL three-necked flask, add 200mL pump oil, 10mL Span 80, stir at 600rpm for 30min, add 10mL saturated calcium chloride dropwise, and continue stirring for 20min. After the reaction, the microspheres are collected by filtration, cleaned with alcohol and deionized water, dried in an oven at 60°C, heated in a muffle furnace to 1200°C, kept for 30 minutes, and cooled naturally to obtain porous ceramic microspheres. The ceramic microspheres were immersed in a 6% agarose solution, incubated at 105°C for 30 minutes, and naturally cooled with 25 mL of deionized water for full grinding, the water was sieved to remove the surface agarose, and the microspheres were washed with deionized water 3 times. The obtained rigid ceramic / agarose composite microspheres have a true wet density of 1.5 g / mL, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com