Abietic resin allyl propionate photo-curing material and preparation method thereof

A light-curing material, allyl acid technology, applied in the direction of coating, etc., to achieve the effect of good acid resistance, good hardness and fast curing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

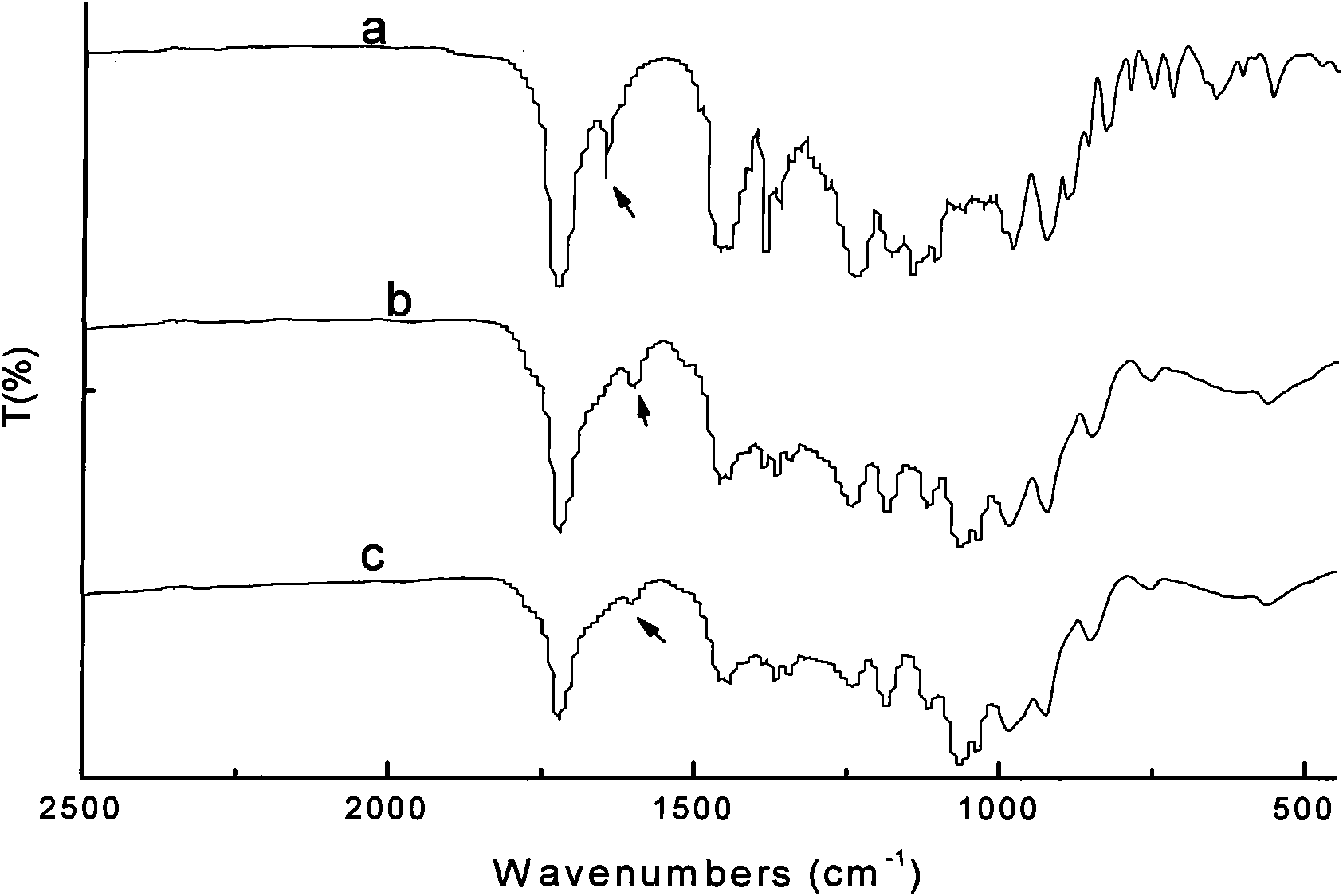

[0053] The preparation method of the allyl rosin resinate photocurable material comprises the steps of: weighing the raw materials in proportion, adding allyl rosin resinate and a conventional photoinitiator into the diluent or active diluent, stirring evenly to prepare Prepolymer solution, the prepared prepolymer solution is made into a uniform liquid film on the tinplate sheet with a wet film preparation device, and put into a UV light curing machine to cure and form a film. After the curing is completed, the rosin resin acid allyl Ester light curing material. After the curing is completed, diluent or active diluent is used to dissolve the cured film formed on the tinplate sheet, carry out infrared spectrum analysis and characterization, and measure the conversion rate of vinyl double bonds.

[0054] When used in conjunction with conventional photocuring monomers, the steps are: Weigh the raw materials in proportion, add allyl rosin resin, conventional photocuring monomers a...

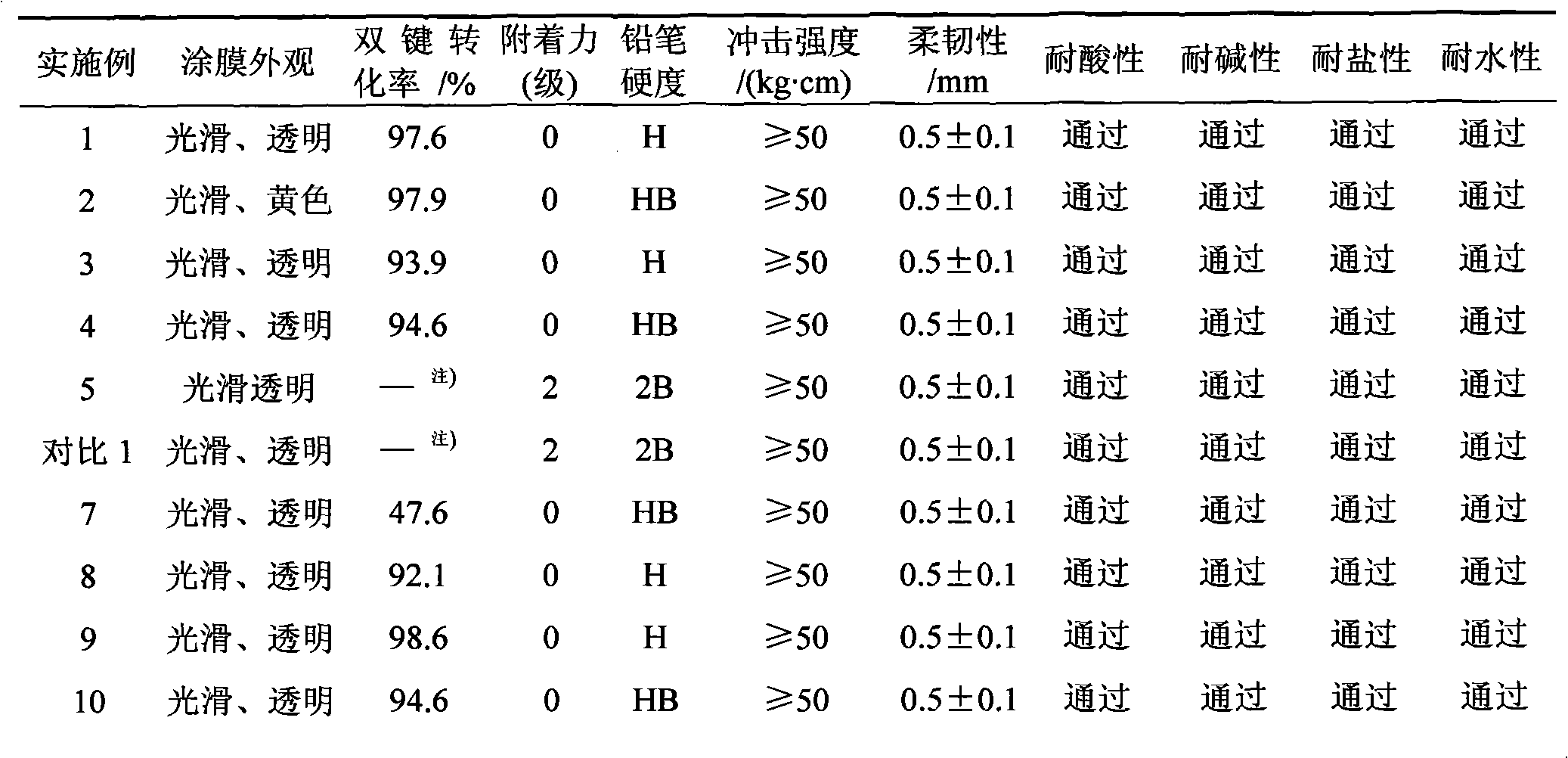

Embodiment 1

[0065] Allyl rosin resinate 50mg, Darocure 1173 photocuring reaction initiator 2.5mg (equivalent to 5% of the mass of allyl resinate) were dissolved in 1.5mL tetrahydrofuran, and stirred evenly to form a prepolymer solution. Use a 100μm wet film preparation device to evenly coat the prepolymer solution on a tin plate with a specification of 80cm×40cm, and place it in a UV light curing machine for curing reaction. The UV curing conditions are: light distance 4.5cm, UV light intensity 100% means the working power is 600W and the light time is 300s. After curing, the performance of the cured film was measured by dissolving the cured film in tetrahydrofuran, and the results are shown in Table 1 (the same below).

Embodiment 2

[0067] 50 mg of allyl rosin resinate, 4 mg of MK photocuring reaction initiator (8% of the mass of allyl resinate), were dissolved in 1.5 mL of tetrahydrofuran, and stirred evenly to form a prepolymer solution. Use a 100μm wet film preparation device to evenly coat the prepolymer solution on a tin plate with a specification of 80cm×40cm, and place it in a UV light curing machine for curing reaction. The UV curing conditions are: light distance 4.5cm, UV light intensity 100% means the working power is 600W and the light time is 250s. After curing, the properties of the cured film were measured.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com