Cerium-ion activated flashing light-emitting material for X-ray detection and method for preparing the same

A scintillation luminescence and X-ray technology, applied in luminescent materials, chemical instruments and methods, etc., to achieve the effects of high light yield, simple preparation process and easy control of conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

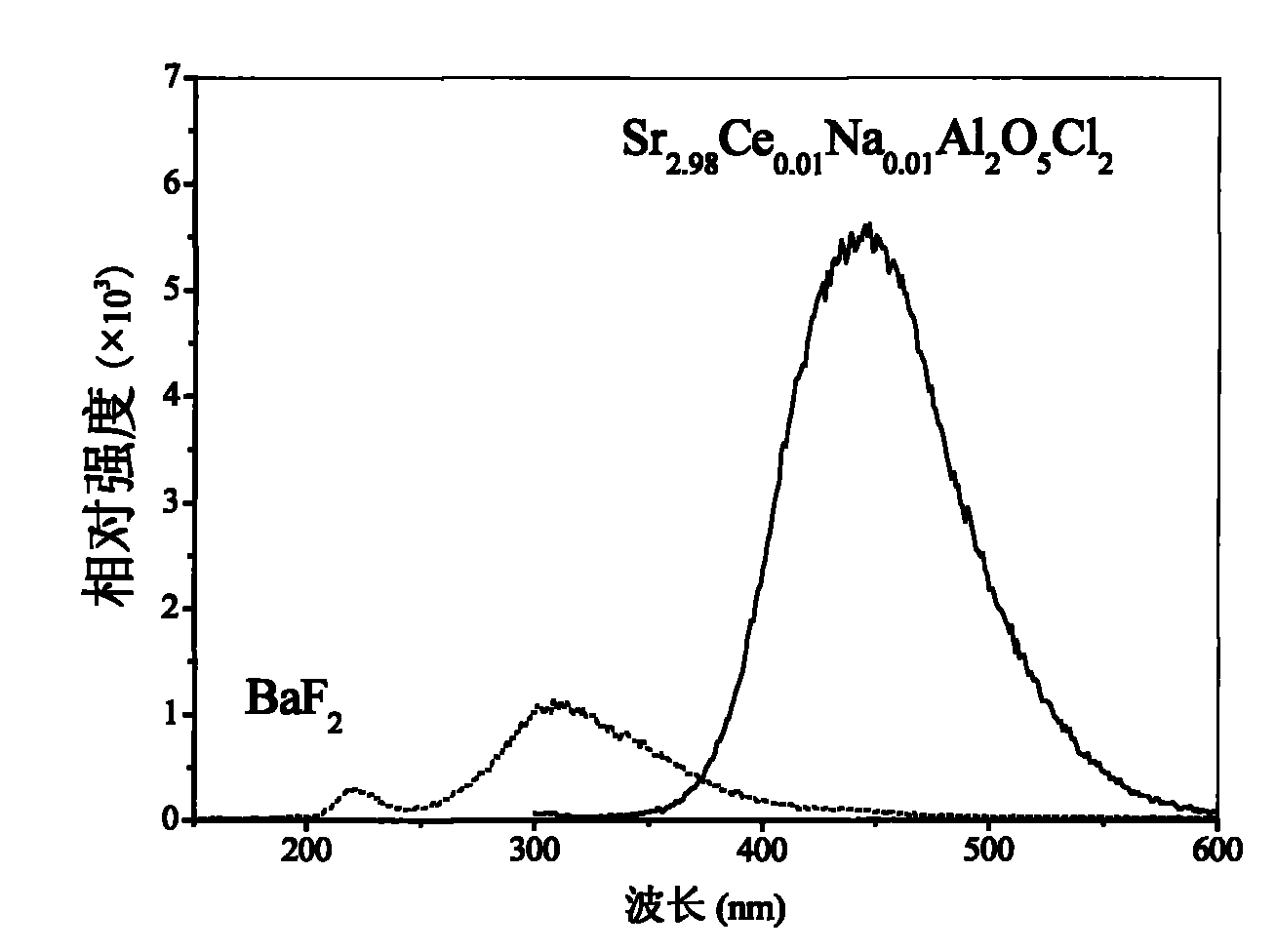

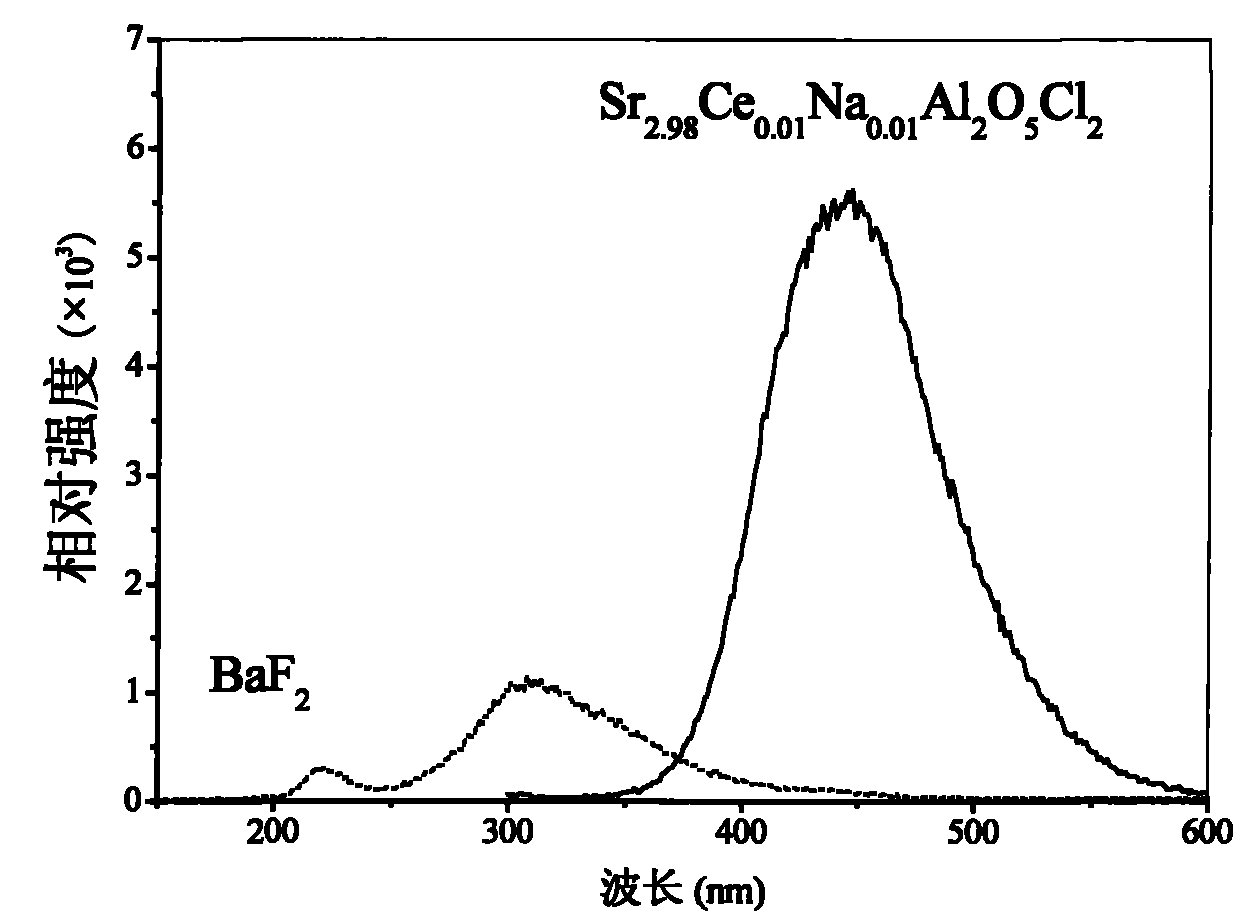

[0013] Weigh anhydrous sodium carbonate (Na 2 CO 3 ) 0.0021g, cerium oxide (CeO 2 ) 0.0069g, aluminum oxide (Al 2 o 3 ) 0.4078g, strontium carbonate (SrCO 3 ) 1.1692g, strontium chloride (SrCl 2 ·6H 2 O) 1.0665g, ground and mixed in a mortar, moved to alumina crucible, 5%H 2 -95%N 2 Calcined at 1000°C for 5 hours under atmosphere. Cooling and grinding, X-ray powder diffraction results of the sample and Sr 3 Al 2 o 5 Cl 2 The standard card (JCPDS no80-0564) is consistent, that is, the composition formula is Sr 2.98 Ce 0.01 Na 0.01 Al 2 o 5 Cl 2 powder scintillation material. When the scintillation material is excited at 340nm, its fluorescence wavelength is between 350nm and 600nm, its strongest emission peak is about 440nm, and the corresponding fluorescence lifetime is 33.8 nanoseconds. Compare the sample with the reference sample BaF 2 Test comparisons under the same conditions, such as figure 1 shown. Calculated sample Sr 2.98 Ce 0.01 Na 0.01 Al 2 ...

Embodiment 2

[0015] This embodiment is basically the same as Embodiment 1, the difference is that Ce is increased 3+ doping content. Weigh anhydrous sodium carbonate (Na 2 CO 3 ) 0.0212g, cerium oxide (CeO 2 ) 0.0688g, aluminum oxide (Al 2 o 3 ) 0.4078g, strontium carbonate (SrCO 3 ) 1.0629g, strontium chloride (SrCl 2 ·6H 2 O) 1.0665g, ground and mixed in a mortar, moved to alumina crucible, 5%H 2 -95%N 2Calcined at 1000°C for 5 hours under atmosphere. Cool and grind to obtain powder scintillation material.

Embodiment 3

[0017] This embodiment is basically the same as Embodiments 1 and 2, the difference is that Ce is further increased 3+ doping content. Weigh anhydrous sodium carbonate (Na 2 CO 3 ) 0.0636g, cerium oxide (CeO 2 ) 0.2065g, aluminum oxide (Al 2 o 3 ) 0.4078g, strontium carbonate (SrCO 3 ) 0.8267g, strontium chloride (SrCl 2 ·6H 2 O) 1.0665g, ground and mixed in a mortar, moved to alumina crucible, 5%H 2 -95%N 2 Calcined at 1000°C for 5 hours under atmosphere. Cool and grind to obtain powder scintillation material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com