Multifunctional gypsum painting ready mixed mortar as well as preparation method and application thereof

A technology for plastering plaster and ready-mixed mortar, which is applied in the field of ready-mixed mortar and can solve the problems of single variety and function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0125] The preparation or commercial purchase source of the test material involved in the present invention

[0126] 1, the preparation of adhesive: be made up of expanded cornstarch, sodium bentonite (or sodium montmorillonite), salicylic acid and sodium diacetate; In order to achieve better effect, adhesive of the present invention is made up of each The components are mixed together to obtain: 96 kg of expanded corn starch, 2 kg of sodium bentonite, 1 kg of salicylic acid, and 1 kg of sodium diacetate; wherein, the expanded corn starch can be purchased from Jiangsu Liyang Huida Machinery Co., Ltd.

[0127] 2. Commercial purchase channels and specifications of other materials:

[0128] β-hemihydrate gypsum was purchased from Guangzhou Changda Trading Company; heavy calcium carbonate was purchased from Tianjin Hongyan Company, and its specification was 400-1250 mesh.

[0129] Calcium hydroxide was purchased from Tianjin Hongyan Company, and its specification was 400 mesh-125...

Embodiment 1

[0131] Example 1 Preparation of multifunctional plaster ready-mixed mortar

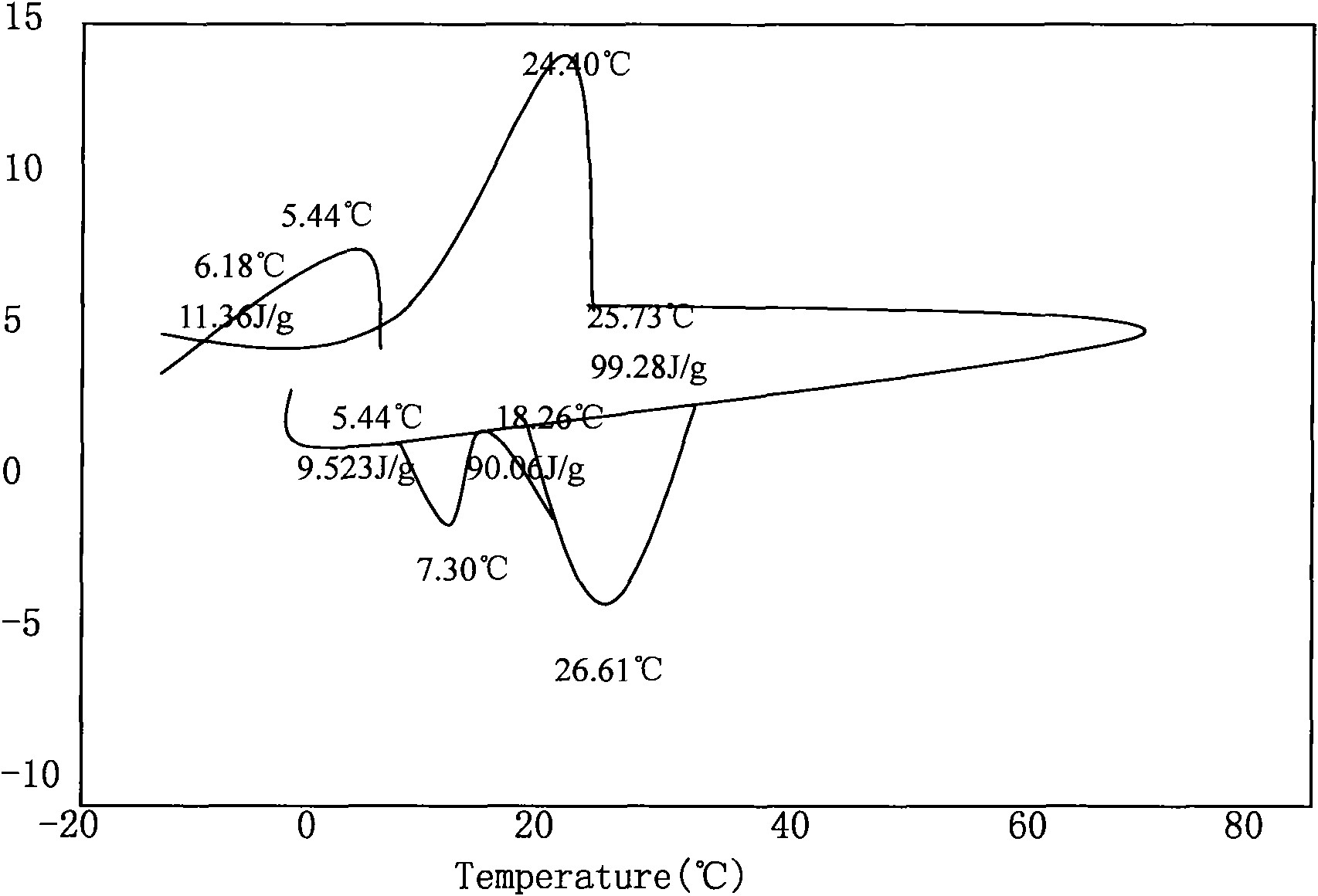

[0132] Weigh each component according to the following weight (unit: Kg): β-hemihydrate gypsum 40, heavy calcium carbonate 20, slaked lime (calcium hydroxide) 20, quartz sand 5, methylcellulose 0.15, adhesive 2, phase change Material (calcium chloride hydrous salt (CaCl 2 ·6H 2 (0)), hydroxypropyl starch 0.05, dispersant sodium pyrophosphate 0.1, anti-shrinkage agent cyclic sodium phosphate 0.15, light calcium carbonate 2.15, heavy stone powder 3, talcum powder 2, tourmaline powder 0.05, diatomaceous earth 2.35;

[0133] Pour β-hemihydrate gypsum, diatomaceous earth, talcum powder, tourmaline powder, and light calcium carbonate into the mixer in turn, mix and stir, and stir forward (76-84 revolutions per minute) for 2 minutes to obtain mixture 1;

[0134]Pour heavy calcium carbonate, anti-shrinkage agent cyclic sodium phosphate, dispersant sodium pyrophosphate, hydroxypropyl starch, and phase change...

Embodiment 2

[0136] Example 2 Preparation of multifunctional plaster ready-mixed mortar

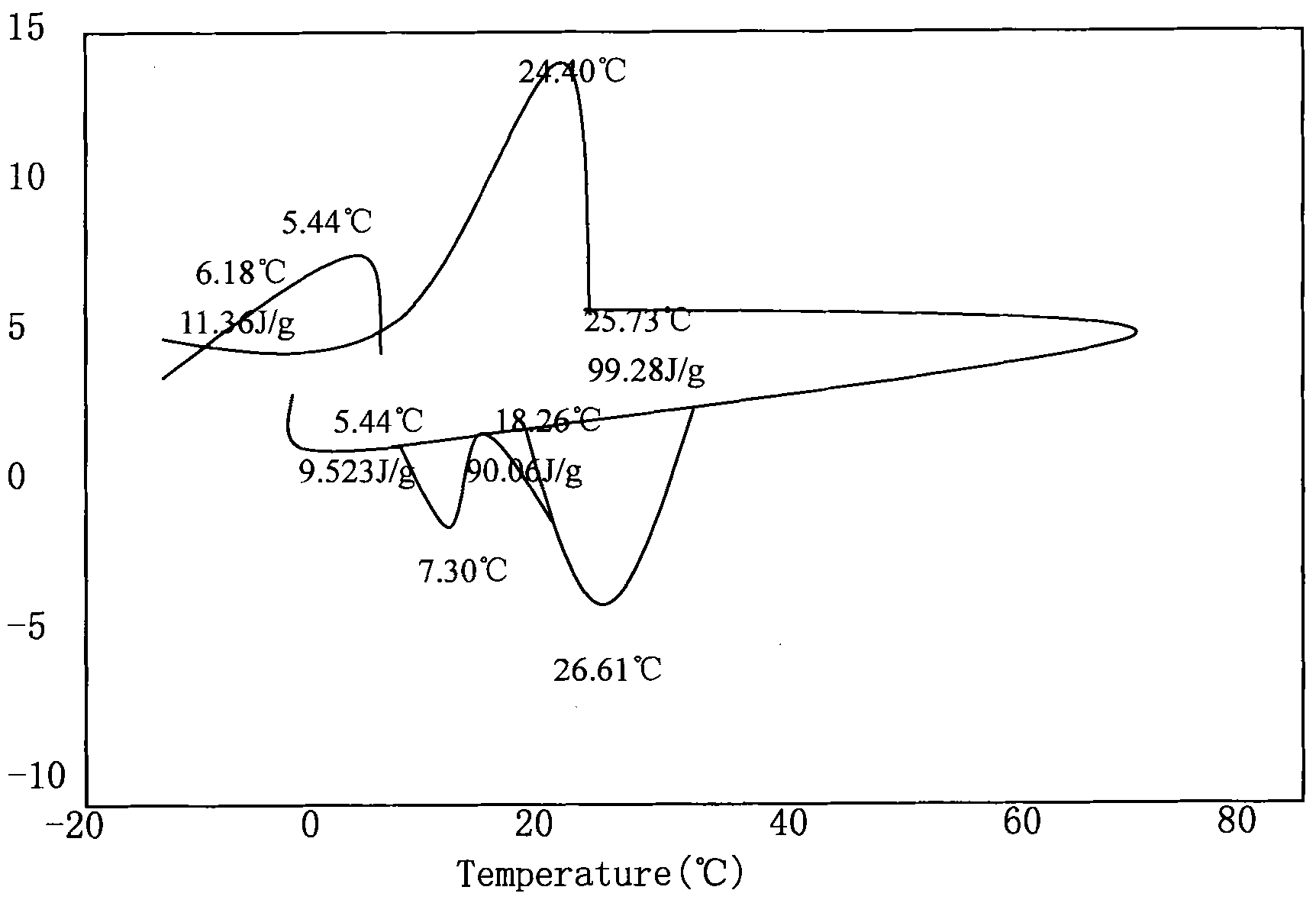

[0137] Take each component (unit: Kg) by the following weight: β-hemihydrate gypsum 50, heavy calcium carbonate 10, slaked lime 10, quartz sand 5, hydroxyethyl methylcellulose 0.15, adhesive 2, phase change material ( Paraffin wax) 5, hydroxypropyl starch 0.05, dispersant sodium pyrophosphate 0.15, anti-shrinkage agent cyclic sodium phosphate 0.12, light calcium carbonate 2.15, barite 5, talcum powder 3, tourmaline 0.2, diatomaceous earth 6.

[0138] Pour β-hemihydrate gypsum, diatomaceous earth, talcum powder, tourmaline powder, and light calcium carbonate into the mixer in turn, mix and stir, and stir forward (76-84 revolutions per minute) for 3 minutes to obtain mixture 1;

[0139] Pour heavy calcium carbonate, anti-shrinkage agent cyclic sodium phosphate, dispersant sodium pyrophosphate, hydroxypropyl starch, and phase change materials into the mixture 1 in sequence, reverse (58-62 revolutions per...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com