Selective laser melting forming device and method of medical magnesium alloy metal part

A technology of selective laser melting and metal parts, which is applied in the field of magnesium alloy parts manufacturing, can solve the problems of difficult to meet requirements, low molding efficiency, waste, etc., achieve high dimensional accuracy and surface finish, smooth powder coating effect, and high molding efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

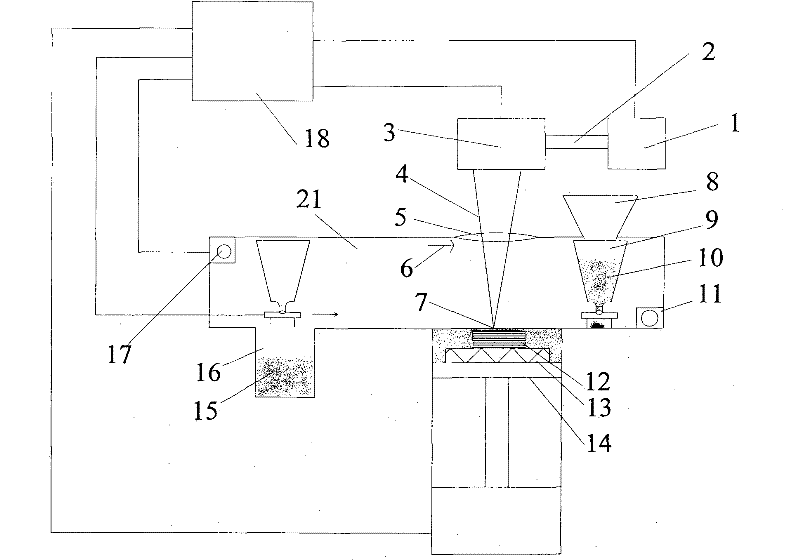

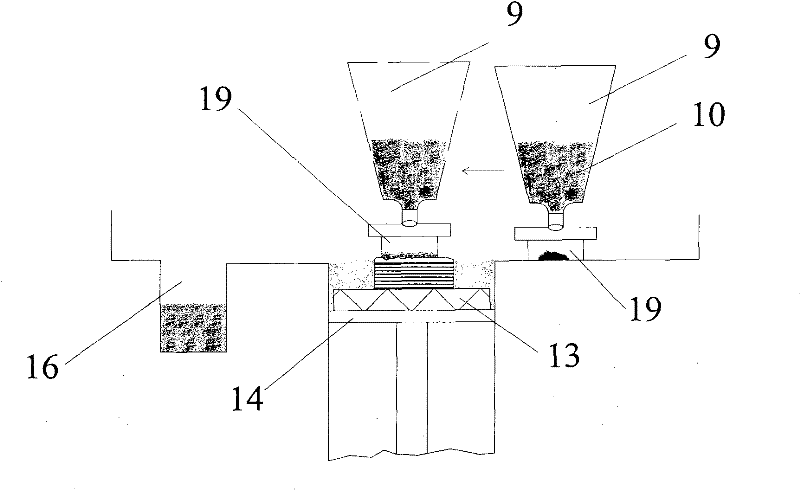

[0058] Such as figure 1 As shown, the selective laser melting forming device for medical magnesium alloy metal parts includes a control device 18, a powder feeding device, a laser transmission mechanism, a gas purification device and a closed forming chamber 21, and the forming chamber 21 is provided with a forming cylinder 14 and recovery cylinder 16, recovery cylinder 16 is located at one side of molding cylinder 14; Described powder sending and spreading device is located in molding chamber 21, comprises hopper 9 and is installed in the powder coating brush on both sides below hopper 9, and described hopper 9 The upper part corresponds to the filling port 8 above the molding chamber 21, and the lower part of the plastering brush corresponds to the upper surface of the molding cylinder 14; The side wall of the molding chamber 21 is provided with an air inlet 17 and an air outlet 11 that are convenient for gas to enter and exit, and the gas purification device is connected to...

Embodiment 2

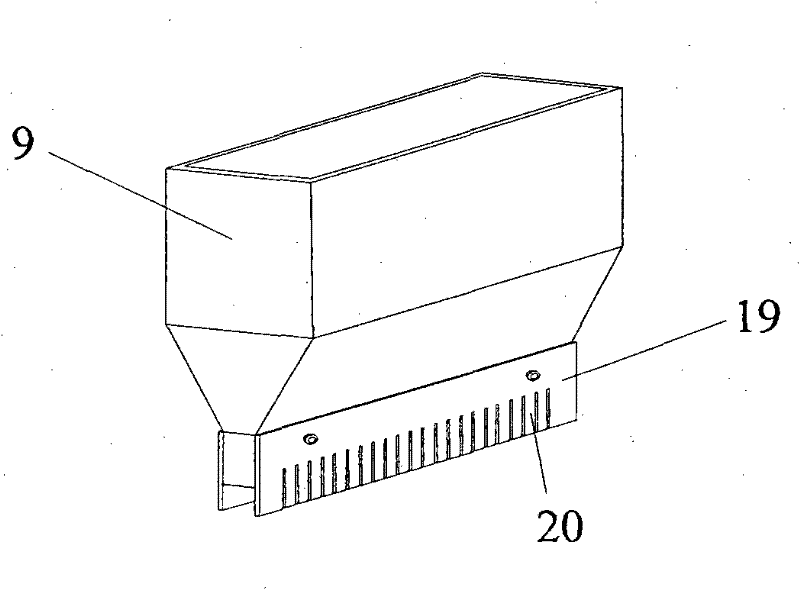

[0087] This embodiment has the same features as Embodiment 1 except for the following features: the plastering brush is four brush sheets 19, two of which are superimposed on each other and located on the lower side of the hopper, and the other two brush sheets are superimposed on each other. and be located on the other side below the hopper 9; the gap between the brush unit 20 of each brush 19 is 0.15mm, and the width of each brush unit 20 is 5mm; the lower end of the scraper is lower than the brush unit The low end of 19 is 200 μm high.

[0088] The brush sheet 19 for painting is made of 100 μm thick 304 stainless steel sheet, and the brush unit 20 of each brush sheet is cut by an ultraviolet fiber laser cutting method, and the gap between the brush unit 20 is the slit width of laser cutting.

[0089] A heating wire is arranged below the molding cylinder 14 .

[0090] The gas knife 6 is 0.2MPa argon.

[0091] The focusing lens is a telecentric lens with a focal length of 2...

Embodiment 3

[0097] This embodiment is the same as Embodiment 1 except for the following features: the plastering brush is six brush sheets 19, three of which are superimposed on each other and located on the lower side of the hopper, and the other three brush sheets are superimposed on each other. and be located on the other side below the hopper; the gap between the brush unit 20 of each brush is 0.1mm, and the width of each brush unit 20 is 4mm; the low end of the scraper is lower than the brush The end height is 100 μm. The brush sheet 19 for painting is made of 50 μm thick 304 stainless steel sheet, and the brush unit 20 of each brush sheet is cut by ultraviolet fiber laser cutting, and the gap between the brush unit 20 is the slit width of laser cutting.

[0098] The gas knife 6 is argon gas of 0.18MPa.

[0099] The focusing lens is a telecentric lens with a focal length of 163mm.

[0100] The power of the fiber laser is 100W, the beam quality M2<1.1, and the laser energy presents ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com