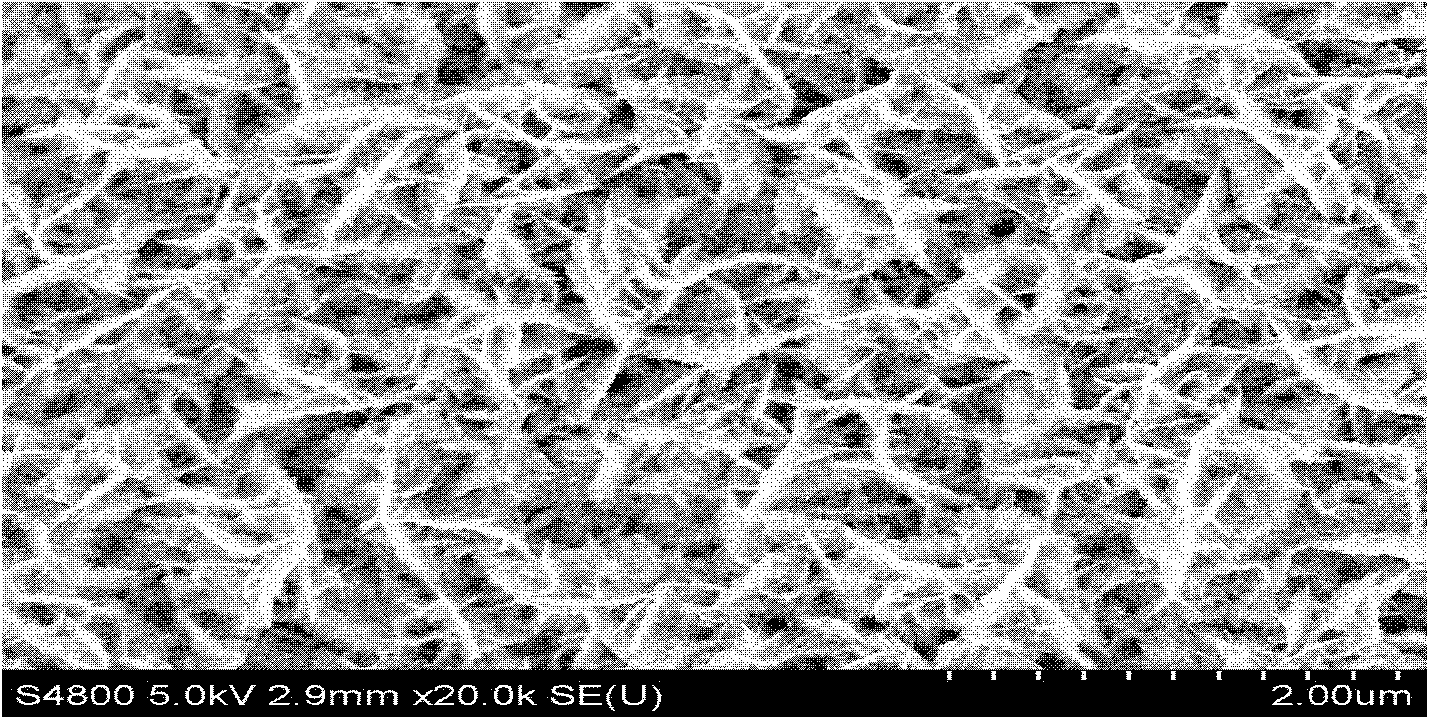

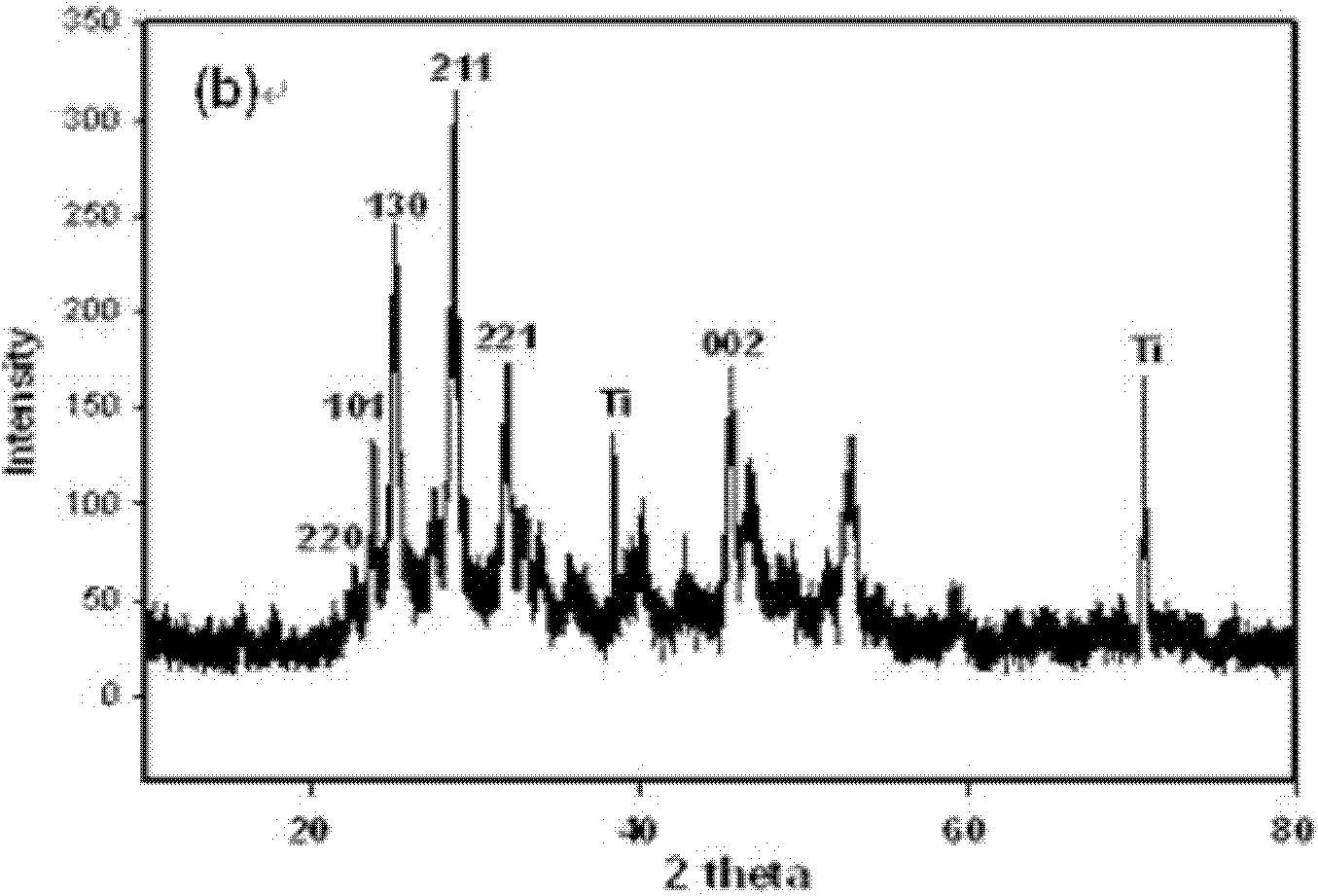

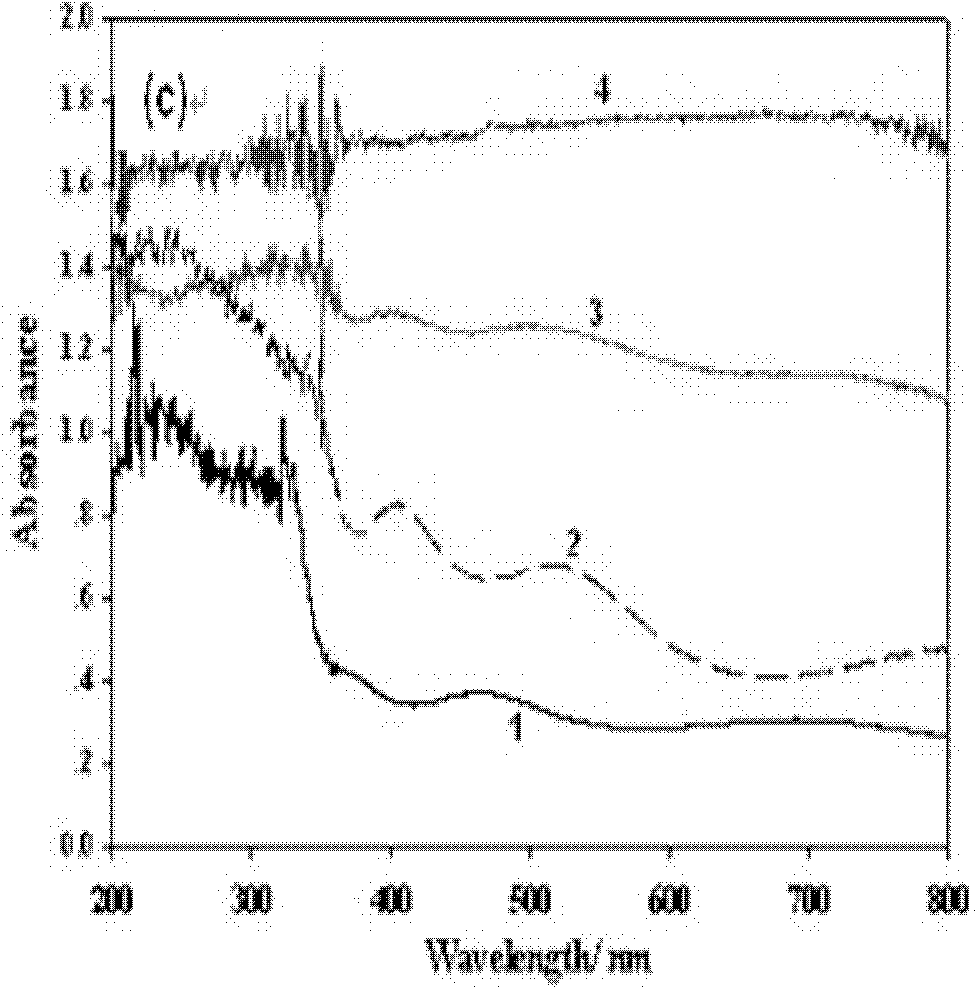

Bi2S3/TiO2 nanotube array and preparation method thereof

A nanotube array, titanium dioxide technology, used in electrolytic coatings, surface reaction electrolytic coatings, coatings, etc., can solve the problems of inability to fully utilize natural sunlight, inability to form nanotube-like structures, and insufficient specific surface area. Photocatalytic efficiency, improving photoelectric conversion efficiency, and the effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] (1) Grinding the surface of the base material, cleaning it for later use;

[0018] (2) Preparation of electrolyte: the electrolyte is composed of hydrofluoric acid and dimethyl sulfoxide or NH with a mass percentage of HF of 0.5-3%. 4 F mass percentage composition is the alcohol solution composition of 0.25-0.5%;

[0019] (3) Under 25-100V DC voltage, using pure titanium or titanium alloy as the anode and platinum sheet as the cathode, electrolytically prepare titanium oxide nanotubes in the electrolyte;

[0020] (4) Calcining the titanium oxide nanotube array prepared above under aerobic conditions at 400°C-500°C for 4-6h to crystallize it into TiO 2 array of nanotubes.

[0021] (5) Bi 2 S 3 Preparation of modified titania nanotube arrays:

[0022] With 0.05mol / L-2mol / L Bi(NO 3 )·5H 2 The sulfur powder of O, 0.1mol / L-3mol / L, the dimethyl sulfoxide of the L-cysteine of 0.12mol / L-3mol / L are plating solution, and taking saturated calomel electrode as reference el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com