Preparation method of Al2O3-SiO3 solid acid catalyst in nuclear shell structure

A solid acid catalyst, al2o3-sio2 technology, applied in chemical instruments and methods, physical/chemical process catalysts, dehydration of hydroxyl-containing compounds to prepare ether, etc., can solve the problems of many by-products, high reaction temperature, high methanol consumption, and achieve The effect of high activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Weigh 11.038 grams of aluminum nitrate and 7.624 grams of hexamethylenetetramine, add 125 milliliters of deionized water, then stir to dissolve them, and record it as solution A. Weigh 0.214 grams of cetyltrimethylammonium bromide, add 20 grams of n-butanol, stir to dissolve it, and record it as solution B. Mix solution A and solution B in a polytetrafluoroethylene-lined autoclave with a certain volume, and seal and stir for 30 minutes. 15 g of silica gel (200-300 mesh, activated at 550° C.) was added under vigorous stirring. Put the reaction kettle into an oil bath, stir and heat vigorously for 24 hours, and the reaction temperature is 150°C. After the reaction, the reactor was cooled to room temperature, and vacuum filtered. Then wash with 2 liters of deionized water for 5 times, rinse with 25 milliliters of ethanol, and then transfer to a vacuum oven at 60°C for 12 hours to dry. Put the dried product into a muffle furnace and bake it at 500°C for 4 hours to obtain...

Embodiment 2

[0032] Referring to the preparation method and steps of Example 1, the difference is that the amount of silica gel is 7.5 grams. Get Al 2 o 320wt% core-shell structure Al 2 o 3 -SiO 2 composite solid acid catalyst.

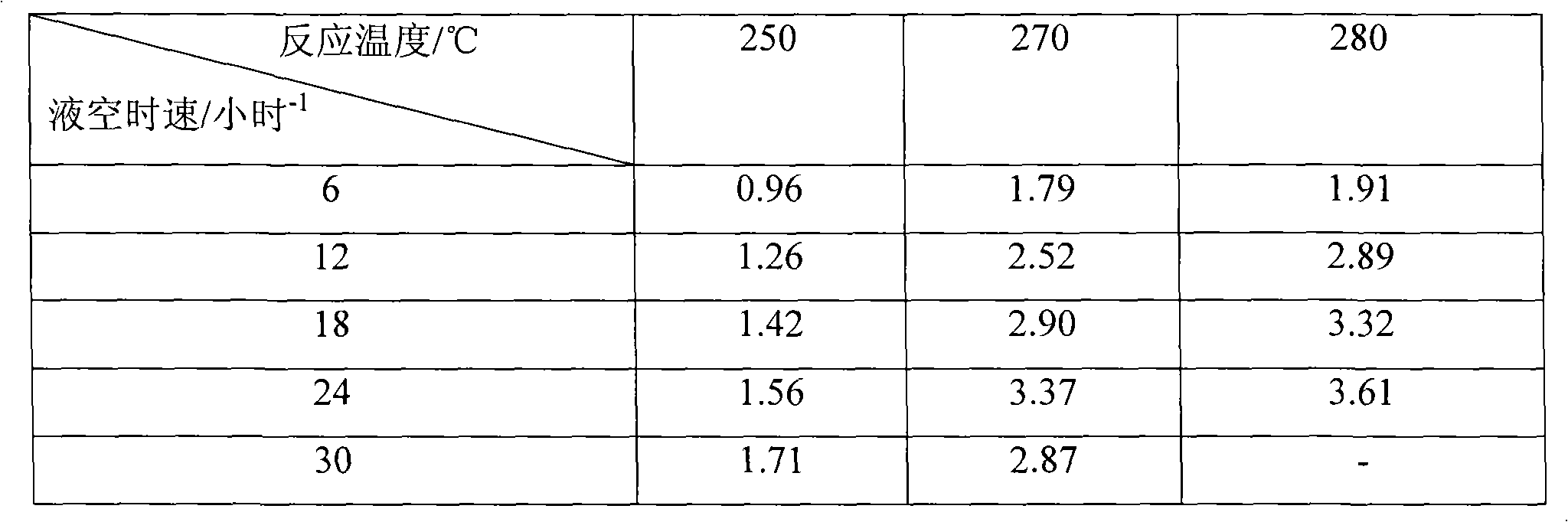

[0033] Weigh 0.2 g of the catalyst prepared by the above method with a particle size of 40-60 mesh, and evaluate the methanol dehydration activity in a fixed-bed reactor.

[0034] Table 2.Al 2 o 3 20wt% core-shell structure Al 2 o 3 -SiO 2 The space-time yield of dimethyl ether on the composite solid acid catalyst ((gram-DME)*(gram-cat) -1 *Hour -1 )

[0035]

Embodiment 3

[0037] With reference to the preparation method and steps of Example 1, the difference is that the amount of silica gel is 3.75 grams to obtain Al 2 o 3 40wt% core-shell structure Al 2 o 3 -SiO 2 composite solid acid catalyst.

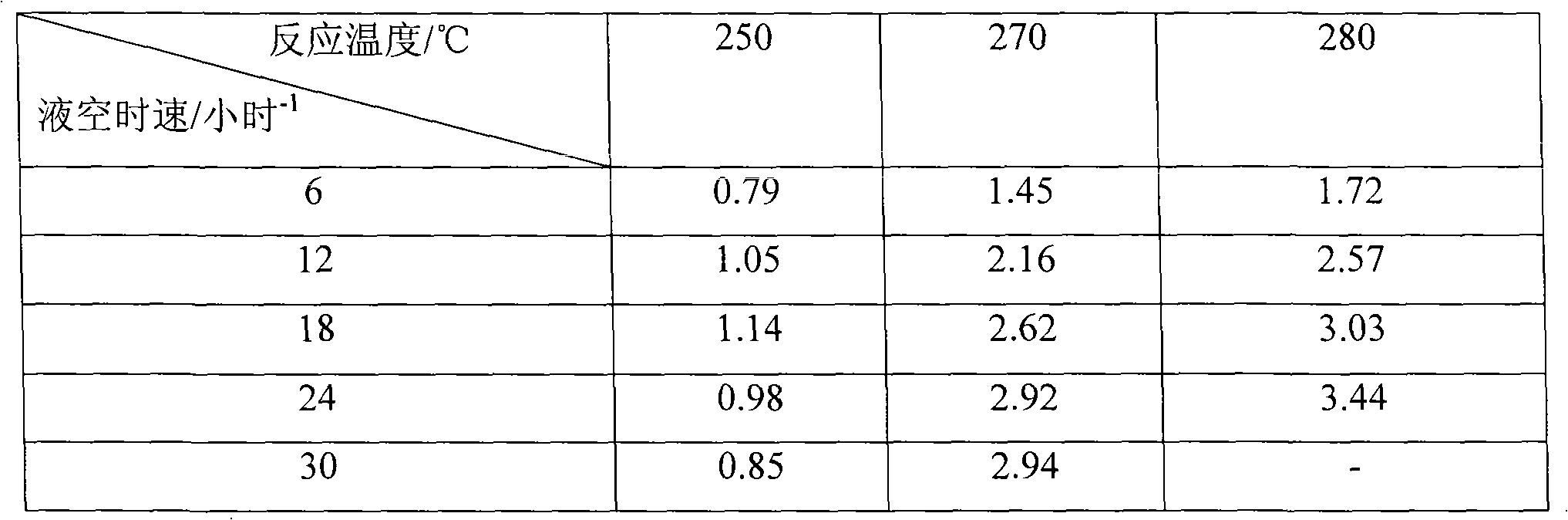

[0038] Weigh 0.2 g of the catalyst prepared by the above method with a particle size of 40-60 mesh, and evaluate the methanol dehydration activity in a fixed-bed reactor.

[0039] Table 3.Al 2 o 3 40wt% core-shell structure Al 2 o 3 -SiO 2 The space-time yield of dimethyl ether on the composite solid acid catalyst ((gram-DME)*(gram-cat) -1 *Hour -1 )

[0040]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com